Military and industrial buyers often face the same dilemma: searching for protective textiles by specification number. One common confusion arises around MIL-PRF-44378E. While it appears in some sourcing lists, it does not actually exist in the official catalog of U.S. military specifications. The correct and relevant designation is PIA-C-44378E, a parachute fabric specification issued by the Parachute Industry Association. From an academic and professional perspective, distinguishing between parachute cloths and true protective fabrics is essential. Parachute cloth focuses on low air permeability and light weight, while fragmentation-resistant textiles emphasize impact absorption and ballistic properties.

Understanding MIL-PRF-44378E and Its Real Scope

The specification PIA-C-44378E defines six types of low-permeability nylon ripstop fabrics, widely used in parachute manufacturing. The differences lie mainly in the air permeability ratings (measured in CFM) and the weights, ranging from 1.17 to 1.5 ounces per square yard. These fabrics are optimized for durability, resistance to tearing, and stable aerodynamic behavior. As an academic researcher, I emphasize that such materials serve a distinct purpose: they are excellent for parachutes but lack the density and layered composition required for fragment protection. For engineers or buyers who misinterpret this code, the outcome may be serious—improper application of fabric in ballistic contexts can compromise safety standards.

What exactly is PIA-C-44378E?

The technical content specifies types I through VI. Type I, for example, maintains 0–3 CFM permeability, while Type VI allows up to 50 CFM. These gradations control how air flows through the fabric, critical to parachute stability and performance. Each fabric undergoes testing in CNAS- or AATCC-certified labs for tensile strength, tear resistance, and dimensional stability. Although highly engineered, they do not exhibit resistance to penetration from high-velocity fragments. Mmi Textiles and PIA provide detailed references.

Is there a MIL-PRF-44378E for protective fabrics?

No official protective version exists. When procurement officers cite MIL-PRF-44378E, they often mistakenly refer to PIA-C-44378E. True fragmentation-resistant textiles fall under entirely different material classes, primarily aramid or UHMWPE composites. This highlights the need for rigorous verification of specifications before acquisition. Fumao Fabric and Flagship Fabric clarify these boundaries.

Correctly Identifying Fragmentation-Resistant Fabrics

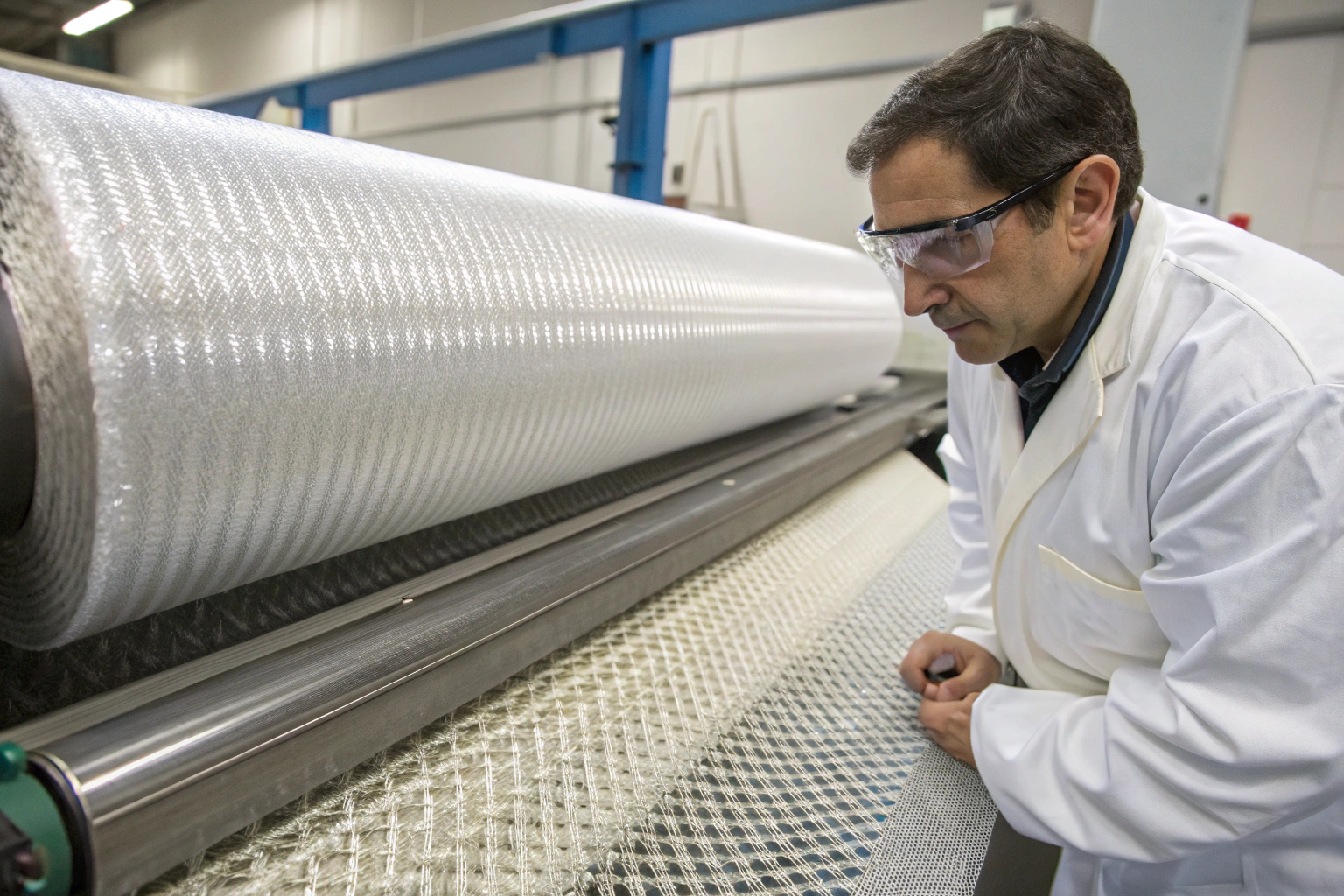

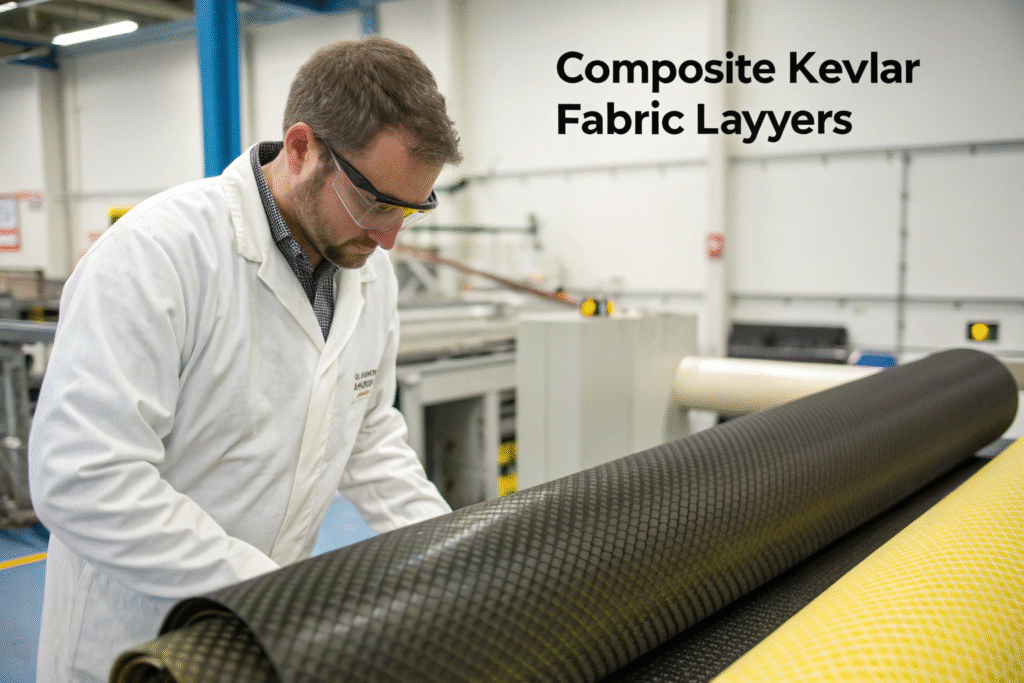

Fragmentation-resistant fabrics must absorb kinetic energy, disperse it across woven layers, and prevent penetration. The most reliable textiles include Kevlar® aramid composites, 1050D ballistic nylon, and UHMWPE (Dyneema®/Spectra®). These are engineered to meet NIJ (National Institute of Justice) standards for ballistic protection. As a researcher, I stress that while parachute nylon and ballistic nylon both carry “nylon” in their names, their structures differ fundamentally: parachute nylon is thin and air-controlled, while ballistic nylon is thick, tightly woven, and layered for resistance.

What fabrics actually work for fragmentation protection?

The standard practice is to rely on aramid fibers like Kevlar® KM2. These fabrics undergo V50 ballistic limit tests, measuring the velocity at which fragments penetrate. Ballistic nylon, first developed during WWII, continues to provide protection in combination with modern resins and coatings. Advanced UHMWPE fibers extend the possibilities with lighter weight and higher resistance. Fabric Catalog HLC and Fumao Fabric give useful insights.

Why not use parachute nylon?

Parachute nylon does not resist impact. It will tear under shrapnel stress. While its tensile strength is high, it lacks the density and laminated construction of ballistic fabrics. In safety engineering, misusing parachute nylon for protective gear is considered a specification error with severe risk consequences. Flagship Fabric explains the aerodynamic intent of parachute fabrics, not protective functions.

Where to Source True Fragmentation-Protective Fabrics

Global sourcing requires precision. HLC Industries provides a wide portfolio of Mil-Spec fabrics, including parachute nylon and ballistic textiles. MMI Textiles specializes in Berry Amendment-compliant ballistic nylon in deniers ranging from 500D to 1050D, widely used in vests and tactical equipment. For international buyers, these suppliers offer not only raw fabric but also certification support and technical datasheets. Academic institutions conducting protective material research also frequently partner with these companies for controlled testing.

U.S. and Global Suppliers of Mil-Spec Protective Fabrics

- HLC Industries: Offers MIL-C-44378 parachute cloth and ballistic nylon for tactical systems. HLC Industries

- MMI Textiles: Provides 1050D ballistic nylon, widely recognized in protective vests and equipment. MMI Textiles

What about fabric suppliers not direct-to-spec?

Other companies, such as Snyder Manufacturing and DAF Products, supply coated fabrics for shelters and covers. While not fragmentation-tested, they support peripheral military needs. They are important when considering environmental resistance but cannot substitute for true ballistic protection. Snyder Manufacturing and Herculite provide these options.

Navigating Specification Confusion and Procurement Tips

Misinterpretation of fabric codes is common in international procurement. To avoid mistakes:

- Verify whether the code is MIL, PIA, or NIJ.

- Request certification documents, including ballistic V50 reports.

- Conduct internal lab testing before bulk purchase.

- Partner with suppliers who maintain R&D support, not just raw fabric supply.

For a company like ours, with expertise in weaving, coating, and inspection, we emphasize due diligence. From academic testing to industrial application, accuracy in specification leads to safety in field operations.

Conclusion

The correct interpretation is that MIL-PRF-44378E does not exist; the real fabric is PIA-C-44378E, designed for parachutes. For grenade fragmentation protection, one must turn to Kevlar®, ballistic nylon, or UHMWPE blends, tested under NIJ or ballistic standards. Buyers must navigate carefully between parachute suppliers and ballistic fabric manufacturers. Companies such as HLC Industries and MMI Textiles remain at the forefront of supplying true protective textiles.

For professional sourcing and production of protective fabrics, you are welcome to contact our team. At Shanghai Fumao, we integrate weaving, coating, inspection, and packaging to meet the strictest global standards. You can reach our Business Director Elaine at elaine@fumaoclothing.com to discuss your specific protective fabric needs.