Products across aerospace, automotive, and consumer industries constantly face stress, damage, and costly repairs. Traditional composites are strong but cannot heal themselves, leading to frequent maintenance and replacements. This gap fuels the demand for smarter materials.

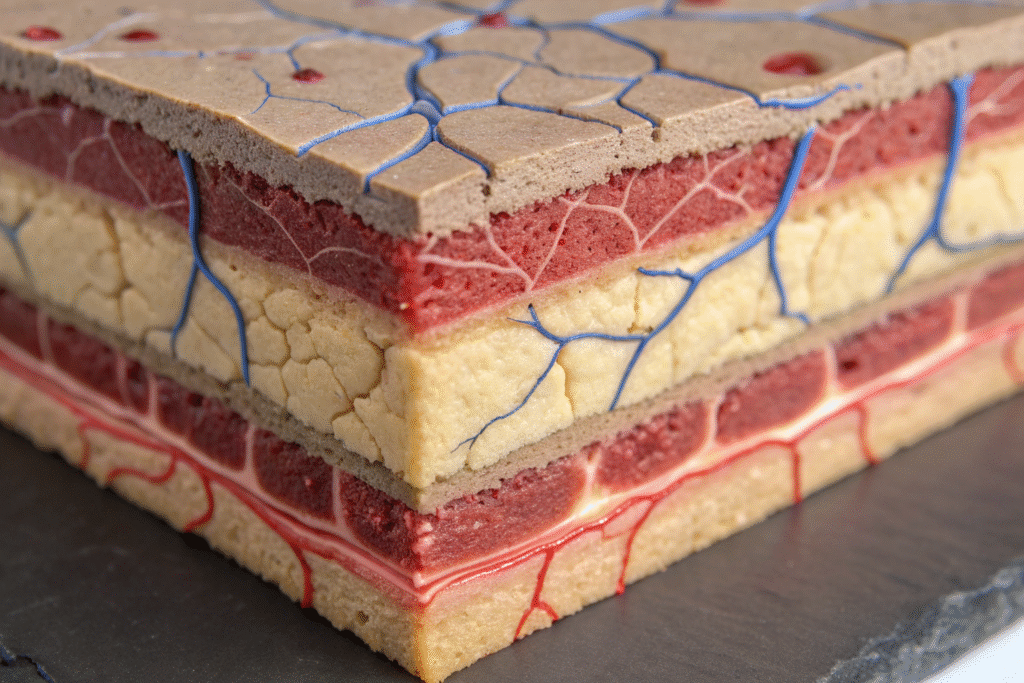

Self-repairing vascular network embedded composites offer a breakthrough by healing cracks automatically, extending service life, and reducing downtime. They mimic the human vascular system, circulating healing agents to repair damage in real time.

This innovation is no longer a concept—it is shaping the future of durable, efficient, and sustainable materials.

How Do Self-Repairing Vascular Composites Work?

Traditional composites fail once cracks appear. In contrast, vascular composites embed a micro-channel system that releases healing agents when damage occurs. This process bonds the structure back together autonomously.

What Makes the Vascular Network Effective?

The vascular design continuously delivers repair agents, enabling multiple healing cycles over the material’s lifetime. This prevents small cracks from escalating into failures.

Why Is Autonomy Important in Material Performance?

Autonomous healing minimizes inspections and repairs. For industries like aerospace, where downtime is costly, these composites ensure safety and efficiency. Learn more about autonomous materials and the NIST research supporting them.

What Are the Key Advantages for Manufacturers?

Manufacturers want lower costs, sustainability, and long-term durability. Vascular composites meet all three.

They reduce maintenance by repairing cracks automatically, extend product life, and support eco-friendly goals by cutting waste.

How Do They Reduce Maintenance Costs?

Self-healing lowers the need for inspections and manual fixes, saving on labor and logistics. See AZoM for cost benefits in advanced composites.

Can They Improve Sustainability in Production?

By reducing replacements, these materials decrease waste and support greener production cycles, as shown in studies from the Journal of Composite Materials.

Where Are These Composites Applied Today?

Self-healing composites are not limited to labs—they are already in use.

Aerospace, automotive, construction, and sports equipment industries are integrating them to improve safety, reduce costs, and increase reliability.

Why Are Aerospace and Defense Leaders Adopting Them?

Aircraft and defense systems benefit from materials that withstand extreme conditions. Self-healing reduces inspection needs and boosts safety. Read about NASA’s work on advanced composites.

Are Consumer Products Also Benefiting?

Yes, from bicycles to smartphones, consumers enjoy longer-lasting products. Learn more from ScienceDirect’s application studies.

What Challenges Still Need to Be Solved?

Despite progress, scaling production and lowering costs remain hurdles. Integrating vascular systems in large structures is complex.

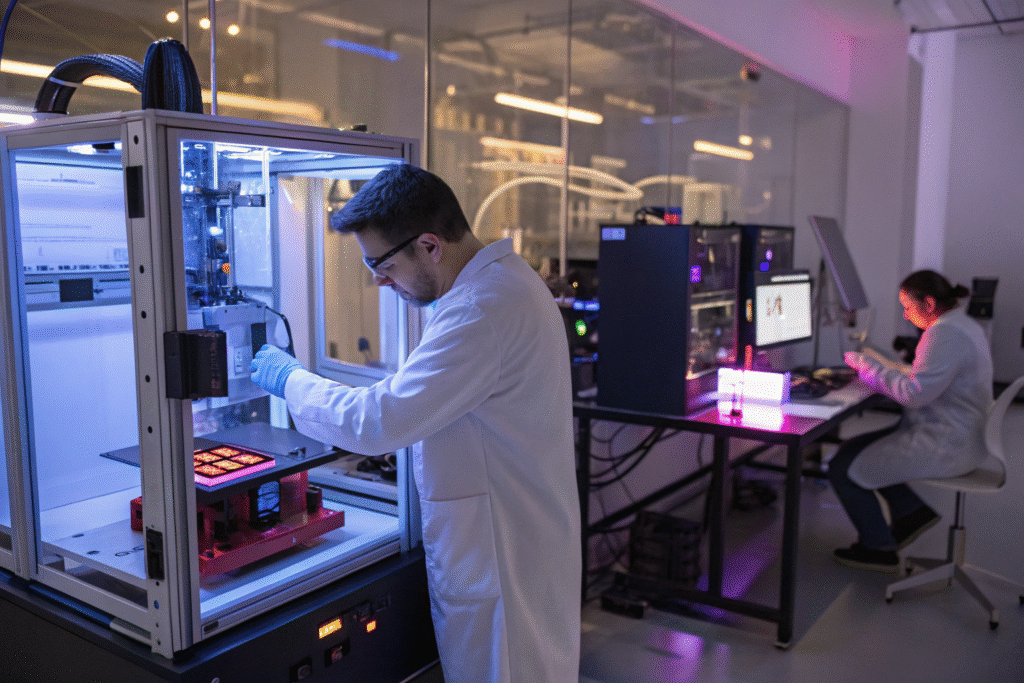

While initial costs are higher, long-term savings and safety gains make adoption worthwhile. Research in 3D printing and nanotechnology continues to push solutions forward.

Are Costs Still a Barrier for Mass Production?

Yes, embedding vascular systems raises expenses. Yet, life-cycle savings offset this challenge. Explore composite economics.

How Is Research Pushing the Boundaries?

Innovations in additive manufacturing make vascular networks easier and cheaper to integrate. Learn more from 3D printing media.

Conclusion

Self-repairing vascular network embedded composites are reshaping durability and sustainability. They extend product life, reduce costs, and enhance safety across industries.

For companies in aerospace, automotive, and consumer markets, adopting these materials is not just an option but an inevitable step forward.

If you are considering innovative fabric or composite solutions for your projects, I invite you to connect with us at Shanghai Fumao. We bring advanced textile expertise and a commitment to co-creating value. Reach out to our Business Director Elaine at elaine@fumaoclothing.com to explore how we can develop your next-generation material solutions together.