Many buyers in the textile industry are exploring smart fabrics that can move, change, or adapt. One of the most exciting options is shape-memory alloy (SMA) textiles. These textiles use wires—usually nickel-titanium—that can contract or bend when heated or powered. For buyers, the main problem is finding reliable suppliers and making sure the products meet both performance and compliance standards.

The short answer is this: focus on trusted suppliers with clear technical specifications, understand how SMA wires are integrated into fabrics, check laboratory testing, and secure dependable logistics. With this guide, you can source these advanced textiles more effectively.

Read on for a step-by-step breakdown tailored to global buyers like you.

Where to Find Reliable SMA Suppliers for Textiles?

Reliable sourcing begins with trusted suppliers of SMA wire. The most common alloy is nickel-titanium (NiTi), also known as Nitinol. Key players include SAES Getters (SAES Getters SMA info) and other companies specializing in shape-memory alloys. These suppliers provide detailed data on transformation temperatures and strain limits, which are critical for textile applications.

When selecting suppliers, always review:

- Alloy composition and transformation range.

- Expected strain (usually 6–8% for NiTi).

- Fatigue cycle life.

- Certification such as ISO or equivalent.

What certification and specs matter most?

Suppliers should provide datasheets showing transformation temperatures, strain capability, and force output. You can review Nickel-titanium data to understand baseline expectations. Testing should also confirm mechanical reliability over many cycles.

Which supplier types suit textile use?

- Medical-grade NiTi wires: very consistent, but costly.

- Industrial-grade SMA wires: suitable for prototyping and bulk orders.

- Fe-based alloys: cheaper alternatives being studied (Fe-based SMA review), though less mature for textiles.

How to Evaluate Textile Integration of SMA?

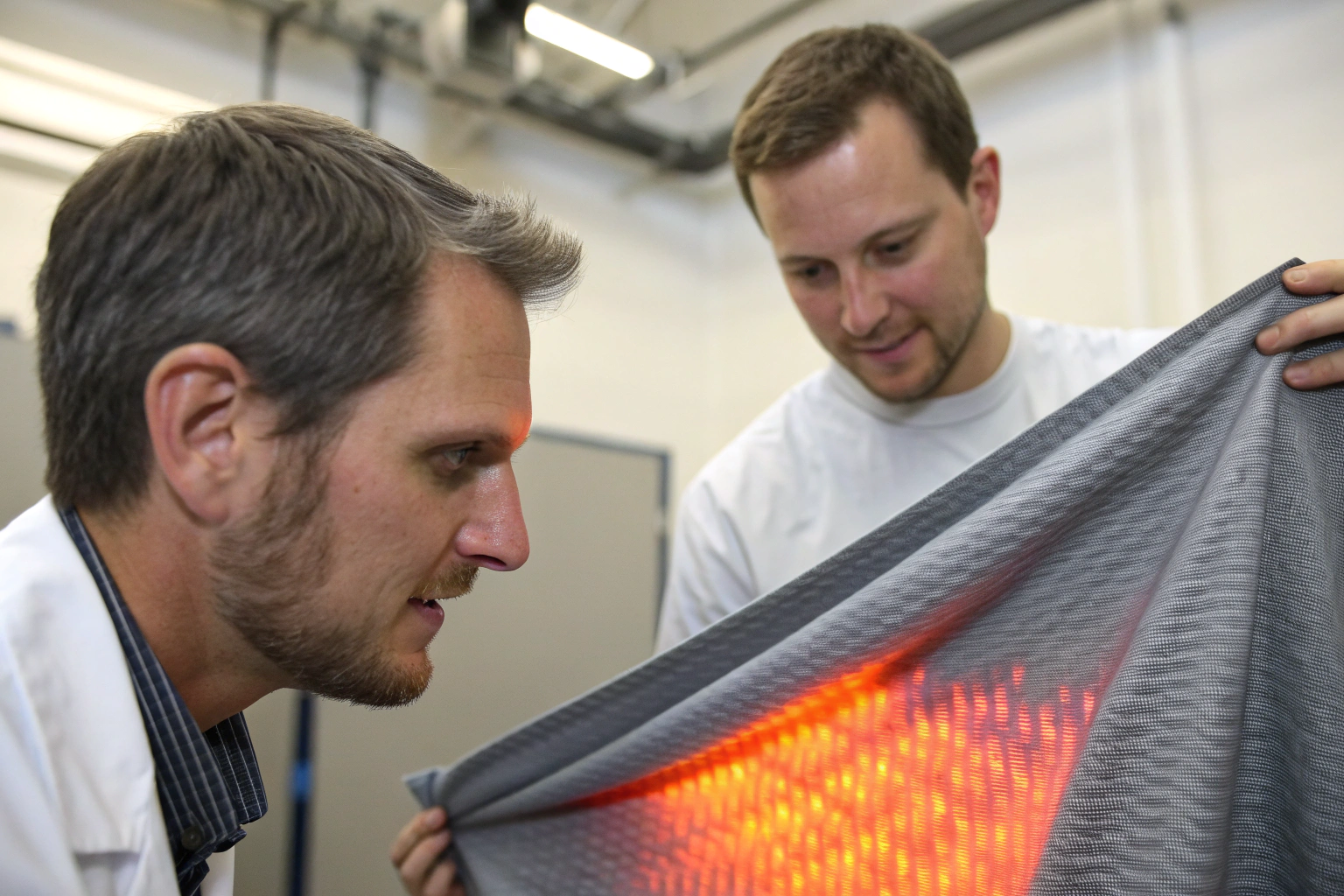

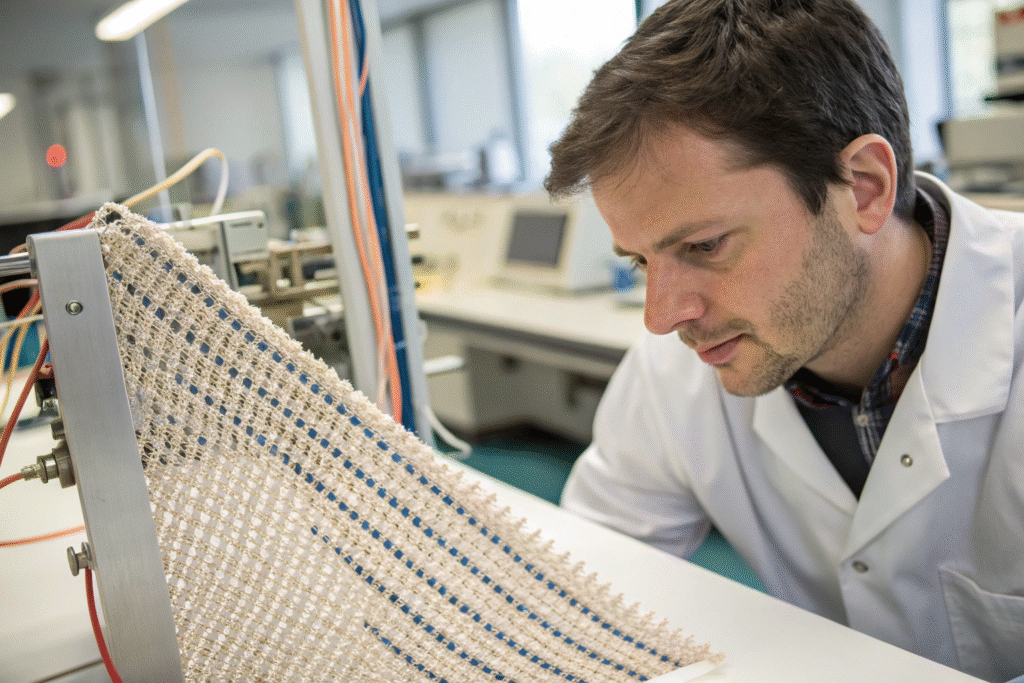

Even the best alloy wire is useless without proper fabric integration. The challenge is to combine SMA with yarns so that the fabric remains flexible but can also move when actuated.

Research shows that knitting SMA wires into fabrics makes them more stretchable and comfortable (SMA textile actuator study). Another promising method is tube-guided SMA wire, which allows longer movement without breaking (Tube-guided SMA actuator).

What textile methods work best?

- Knitting: integrates SMA directly into yarn loops.

- Tube-guided routing: wires move inside small tubes, improving performance.

- Layered composites: SMA placed between textile layers for durability.

What to request in samples?

Ask for sample fabrics that clearly show:

- Actuation stroke and recovery speed.

- Cycle life demonstration.

- Sewing or weaving quality.

What Quality & Compliance Checks Are Essential?

Smart textiles must pass both performance and safety checks before they reach the market. Buyers should never skip this step.

What tests should smart textiles pass?

- Cycle testing to measure long-term actuation.

- Thermal safety checks to confirm safe heating levels.

- Electrical safety if the textile requires current for actuation.

- Chemical compliance with REACH and RoHS.

What documents to demand?

- Lab reports showing test results.

- Safety data sheets for the SMA and coatings.

- Certificates for export compliance.

How to Ensure Logistics & Cost-Effective Supply?

Even after technical approval, sourcing is incomplete without clear logistics and pricing.

What logistics to plan?

- Confirm supplier lead times and stock availability.

- Review shipping documents and HS code classification.

- Use multimodal freight (air, sea, bonded warehouse) for global coverage.

What pricing details to clarify?

- Transparent unit cost (SMA wire + fabric base).

- Clear differences between sample and bulk pricing.

- Payment terms, deposits, and secure banking.

Conclusion

To source shape-memory alloy actuated smart textiles effectively:

- Select suppliers with proven alloy quality.

- Verify fabric integration methods (knit, tube, or layered).

- Ensure compliance with safety and environmental standards.

- Plan logistics and pricing to avoid hidden costs.

Working with Shanghai Fumao Fabric, you benefit from full-service support: design, sample development, bulk production, and global shipping. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to launch your next smart textile project.