When dealing with cryogenic environments—temperatures below -150°C—choosing the right fabric is not just a matter of comfort, but one of safety, durability, and performance. Many industries like aerospace, medical technology, energy, and research facilities require materials that can maintain integrity and protect workers or equipment under extreme cold. However, not all fabrics are capable of handling the brittleness, condensation, and pressure changes associated with cryogenic conditions.

The best fabrics for cryogenic applications are those specifically engineered with insulation, durability, and protective barriers against liquid gases, while ensuring flexibility in sub-zero environments.

In this article, I will explore the most effective fabrics for cryogenic applications, covering their properties, applications, and why they outperform conventional textiles. Let’s dive deeper into the details.

What Properties Make a Fabric Cryogenic-Ready?

Cryogenic applications demand much more than thermal insulation. The wrong choice can result in frostbite, equipment failure, or leakage during handling of liquid nitrogen, oxygen, or hydrogen.

Cryogenic fabrics must combine insulation, impermeability, and mechanical strength while maintaining flexibility under extreme cold.

Why Is Thermal Insulation Critical in Cryogenic Environments?

Thermal insulation is the first line of defense against extreme cold. Fabrics like aerogel composites and multi-layer aluminized films minimize heat transfer while preventing condensation buildup. These materials are widely used in aerospace and medical containers because they dramatically reduce energy loss.

How Do Barrier Fabrics Protect Against Liquid Gas Exposure?

Barrier fabrics such as PTFE-coated textiles are resistant to liquid penetration, preventing dangerous direct contact with liquid nitrogen or oxygen. These coatings also resist chemical degradation, ensuring long-term protection.

Which Synthetic Fabrics Perform Best in Cryogenic Settings?

Not all synthetics are suitable at -150°C and below. Some become brittle, while others maintain flexibility and toughness.

Aramid fibers (like Kevlar® and Nomex®) and PTFE-coated fabrics are industry leaders for cryogenic safety suits and equipment covers.

Can Aramid Fabrics Handle Ultra-Low Temperatures?

Yes. Aramid fibers such as Kevlar® retain mechanical strength even at extreme cold. They are used in cryogenic gloves, aerospace insulation, and structural reinforcement because they resist cracking under sudden thermal shocks.

Why Is PTFE-Coated Fabric a Standard Choice?

PTFE-coated fiberglass combines thermal resistance with liquid impermeability. It prevents cryogenic liquids from penetrating clothing layers. Companies like Saint-Gobain Performance Fabrics supply these advanced coated textiles to industries handling liquid gases daily.

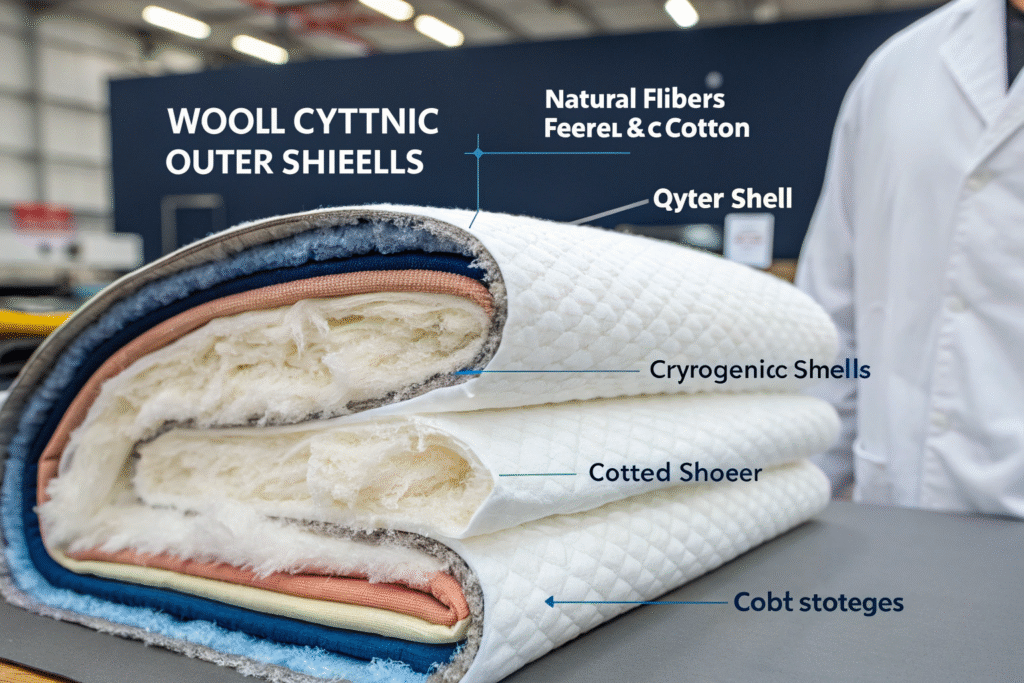

Are Natural Fabrics Suitable for Cryogenic Applications?

Natural fibers like cotton and wool have excellent insulation properties at regular cold conditions, but under cryogenic temperatures, their performance varies.

Natural fabrics are generally not recommended for direct cryogenic exposure but may serve as secondary insulation layers.

Can Wool Still Provide Insulation in Extreme Cold?

Wool has natural insulating and moisture-wicking properties. In cryogenic gear, it is often used as an inner lining layer to enhance wearer comfort. For instance, Merino wool is lightweight and thermoregulating, making it a valuable supportive material when combined with technical outer layers.

Why Is Cotton Risky in Cryogenic Use?

Cotton absorbs moisture easily, which can lead to ice buildup and stiffness at cryogenic temperatures. Although it can be blended into multilayer garments, pure cotton is avoided in critical applications. Industry standards such as OSHA’s guidelines on PPE emphasize avoiding absorbent fabrics in these environments.

What Innovations Are Emerging in Cryogenic Fabrics?

Technology continues to push the limits of textile engineering for extreme cold.

Hybrid composites and nanomaterial coatings are redefining what fabrics can achieve in cryogenic insulation and safety.

How Do Aerogel-Infused Fabrics Change the Game?

Aerogel is one of the world’s lightest and most insulating materials. New textile composites incorporating aerogel provide superior thermal barriers without adding weight. NASA and Aspen Aerogels have pioneered solutions for aerospace and cryogenic industries.

Can Nanotechnology Improve Cryogenic Fabric Safety?

Yes. Nanocoatings add hydrophobic, anti-ice, and flame-retardant properties to fabrics without compromising flexibility. For example, NanoTex® finishes are being adapted to improve protective clothing for workers handling cryogenic fuels.

Conclusion

Selecting the best fabric for cryogenic temperature applications is not just about insulation—it’s about combining thermal protection, chemical resistance, and flexibility. Aramid fibers, PTFE-coated fabrics, and advanced composites lead the field, while wool and other natural fibers serve as secondary supportive layers. With innovations like aerogel composites and nanotech coatings, the industry is moving toward lighter, safer, and more effective cryogenic textiles.

If you are sourcing cryogenic-ready fabrics for industrial, aerospace, or research needs, Shanghai Fumao can provide tailored solutions with our end-to-end fabric production and testing capabilities. To start developing your own cryogenic fabric project, reach out to our Business Director Elaine at elaine@fumaoclothing.com.

One Response

I must voice my gratitude for your kindness giving support to visitors who actually need help with this important issue. Your real commitment to passing the solution across turned out to be quite practical and have in most cases allowed girls like me to arrive at their desired goals. This warm and friendly suggestions can mean a whole lot a person like me and even more to my mates. Many thanks; from all of us.