Modern fashion and smart wearables are moving far beyond simple aesthetics. Today, many brands and developers are asking how to add programmable haptic feedback to textiles. The problem is that this area sounds futuristic and complex, so most buyers and designers feel uncertain about what the basic requirements are. Without clear knowledge, they risk investing in the wrong technology or suppliers.

The minimum requirements for programmable haptic feedback textiles are a reliable actuation mechanism, programmability, seamless integration into fabric, low-power operation, and optional sensing for interactivity. These elements ensure that the fabric delivers real tactile sensations without losing softness or comfort.

This topic is not only relevant for research labs. Fashion houses, sportswear developers, and medical device makers are all exploring haptic textiles. In the following sections, I will explain the five essential factors that define the minimums for programmable haptic feedback textiles and show how they apply to real industry use cases.

What Is the Core Actuation Mechanism?

The first requirement for haptic feedback textiles is the actuation system. Without a way to create physical sensation, the fabric is just passive.

Actuation mechanisms for haptic textiles can be magnetic, fluidic, pneumatic, or electroadhesive. Each one provides different tactile qualities while remaining lightweight and flexible.

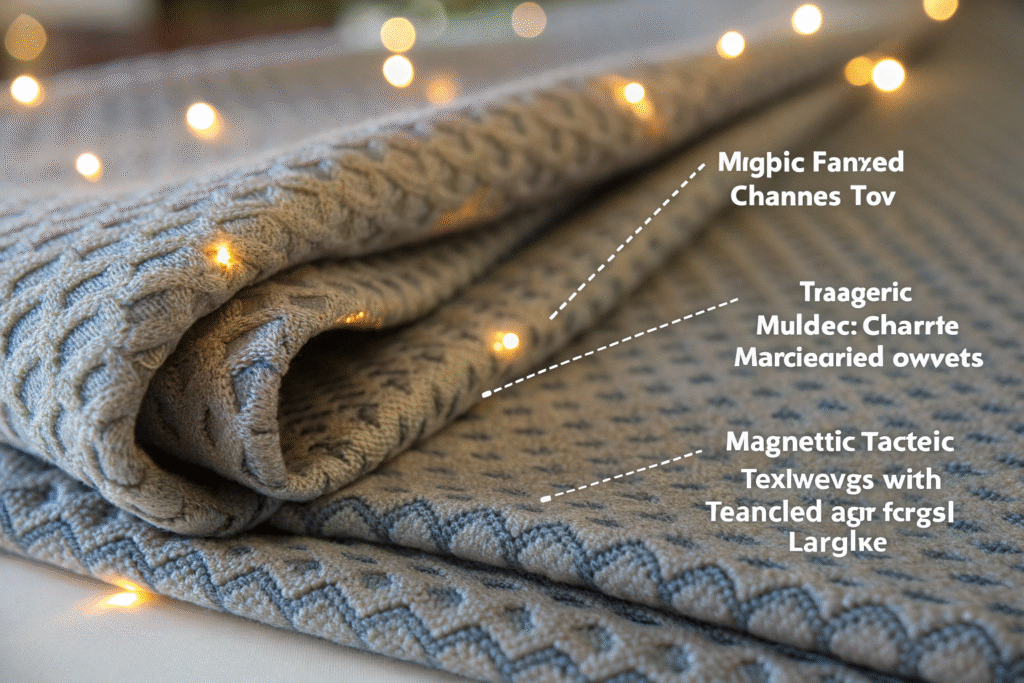

In practice, magnetic systems like MagKnitic embed magnets and ferromagnetic yarns into knitted textiles. This design delivers tactile resistance without requiring high energy input. Meanwhile, fluidic channels allow the fabric to inflate and create pressure sensations. Another approach is electroadhesion, which restricts or releases motion with very low power demand.

Why Does Fabric Integration Matter?

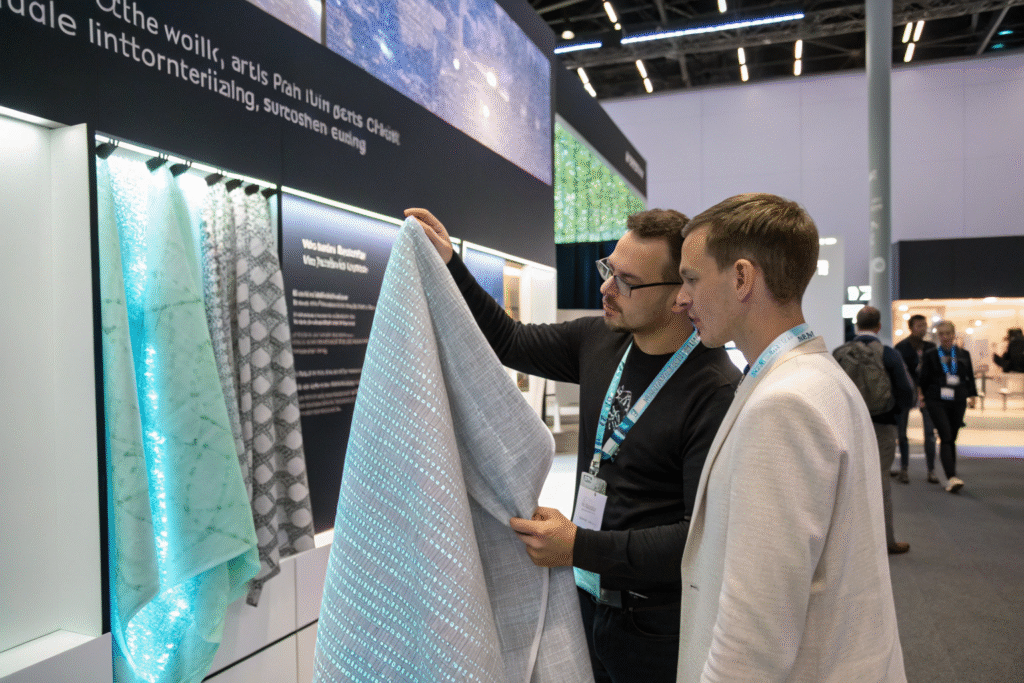

When I tested prototype fabrics from partners, I realized that actuation often made the fabric stiff. If the feedback system compromises softness, the textile loses value. This is why seamless integration of actuators into the fabric weave or knit is crucial. Suppliers who can knit or laminate the actuation elements directly into the fabric structure will be ahead of others.

Which Actuation Type Is Best?

The choice depends on the end use. Sportswear companies prefer low-power electroadhesion for training gear, while luxury fashion may prefer fluidic or magnetic systems for artistic expression. The minimum requirement is that the actuation system must be soft, reliable, and compatible with large-scale textile production.

How Important Is Programmability?

Even with an actuator, the fabric must be programmable. Otherwise, the haptic experience cannot be controlled.

Programmability is the ability to adjust timing, intensity, and pattern of haptic signals, making the fabric more interactive and valuable.

In fluidic systems, programmability comes from controlling air or liquid pressure in channels. In magnetic textiles like MagKnitic, programmability is achieved by digitally designing the pattern of magnetic and ferromagnetic yarn placement. In electroadhesive sleeves, control circuits determine how much resistance is applied at each joint.

What Does Programmability Add for Buyers?

When I discussed with clients in Europe, they often asked if the haptic fabrics could adapt for multiple uses, such as gaming, medical rehabilitation, and fashion. Programmability ensures that the same textile can be reconfigured for different applications. This reduces costs and increases flexibility.

What About Digital Integration?

Programmability also opens the door to software integration. Designers can sync haptic textiles with apps, VR experiences, or IoT platforms. For example, virtual reality companies already test programmable gloves for gaming. The minimum here is that textiles must allow software to change the feedback output easily.

How Can Haptic Elements Be Integrated Into Textiles?

Integration is one of the biggest challenges. Buyers worry that haptic components will make textiles heavy or uncomfortable.

Haptic systems must be embedded in the fabric itself, keeping softness and flexibility intact while delivering reliable tactile signals.

Digital knitting techniques embed ferromagnetic yarns directly into fabric. Fluidic textiles use sealed elastic channels laminated between textile layers. Electroadhesive elements can be printed or coated onto textile substrates.

What Problems Do Buyers Face?

One client once complained that a haptic sleeve prototype felt like wearing a plastic pipe. This shows why integration is not optional. The market minimum is a textile that looks and feels like real fabric while carrying haptic features.

Which Industries Care Most About Integration?

Sportswear and fashion brands cannot compromise on softness, while medical applications care about durability and washability. According to Textile World, seamless integration methods are a primary focus of ongoing smart textile R&D. The takeaway is simple: no integration, no adoption.

Is Sensing a Necessary Feature?

While not a strict minimum, many programmable haptic textiles also integrate sensing functions.

Sensors allow textiles to detect motion, pressure, or touch, creating a feedback loop that makes haptic signals adaptive and interactive.

MagKnitic fabrics detect contact through resistance changes when conductive yarn meets magnets. Other smart fabrics use resistive or capacitive sensing grids. This makes possible adaptive systems where feedback changes based on user interaction.

Why Do Buyers Care About Sensing?

Clients in rehabilitation technology ask if haptic sleeves can detect user movement and give real-time feedback. Fashion buyers ask if garments can react to touch. The answer depends on whether sensing is integrated. According to Wiley Smart Materials, integrated sensing is already redefining textile interactivity.

Is It a Minimum or a Bonus?

While sensing is not a strict minimum, it quickly becomes expected in advanced markets. For many buyers, programmability without sensing feels incomplete. In my experience, companies who prepare for sensing now will gain a stronger position in the global smart fabric supply chain.

Conclusion

Programmable haptic feedback textiles require five core elements: a reliable actuation mechanism, programmability, seamless integration into fabric, low-power operation, and optional sensing. These are the market minimums that every buyer, developer, or supplier must understand. Without them, the textile cannot deliver real value in fashion, sportswear, or medical industries.

If you are exploring ways to co-develop programmable haptic fabrics, Shanghai Fumao is ready to help. We combine large-scale weaving, dyeing, printing, and coating with professional R&D and QC teams. To discuss your project, please reach out to our Business Director Elaine at elaine@fumaoclothing.com.