In space, even the simplest action like drinking water or handling liquids becomes a technical challenge. Without gravity, fluids do not pour or flow the way they do on Earth. They tend to form floating globules, stick to surfaces, or spread unpredictably. For astronauts and engineers, finding the right fabrics to control, absorb, and channel fluids in zero-gravity environments is essential.

The best fabrics for zero-gravity fluid management are those that balance capillary action, absorbency, hydrophobic or hydrophilic properties, and durability under space conditions. These textiles can range from highly engineered synthetic fibers to advanced coatings on traditional fabrics, all designed to help astronauts handle water, waste, and even scientific experiments safely.

The journey to space-friendly fabrics is a fascinating mix of material science and space engineering. Let’s explore what makes certain textiles suitable for this unique application.

How Do Fabrics Behave Differently in Zero Gravity?

In microgravity, fluids cling to surfaces rather than falling. This means fabrics must rely on surface tension and capillary action to move or hold liquids.

Fabrics with fine pores and tightly woven structures, such as microfiber polyester or nylon, encourage capillary wicking. These materials allow fluids to be guided along fibers instead of floating freely. At the same time, coatings like hydrophobic treatments can push liquids away, preventing saturation in areas where moisture is unwanted.

Why Is Capillary Action Important in Space?

Capillary action replaces gravity as the driving force for fluid movement. Fabrics that maximize this effect can channel fluids into collection systems or hold them securely for disposal. For instance, NASA’s research on capillary flow experiments shows how structured textiles can control liquid distribution in zero-gravity.

Another example is the use of porous wicks in water recovery systems. These fabrics allow astronauts to manage fluids without spills, which could otherwise damage electronics or contaminate the cabin environment.

Can Hydrophobic Fabrics Help Prevent Fluid Spread?

Yes. Hydrophobic coatings or fibers like PTFE (Teflon-coated textiles) repel liquids, which helps confine fluids to designated areas. For example, Gore-Tex fabrics have been studied for their ability to let vapor escape while blocking liquid water. This property can be adapted to spacecraft life support systems where moisture control is critical.

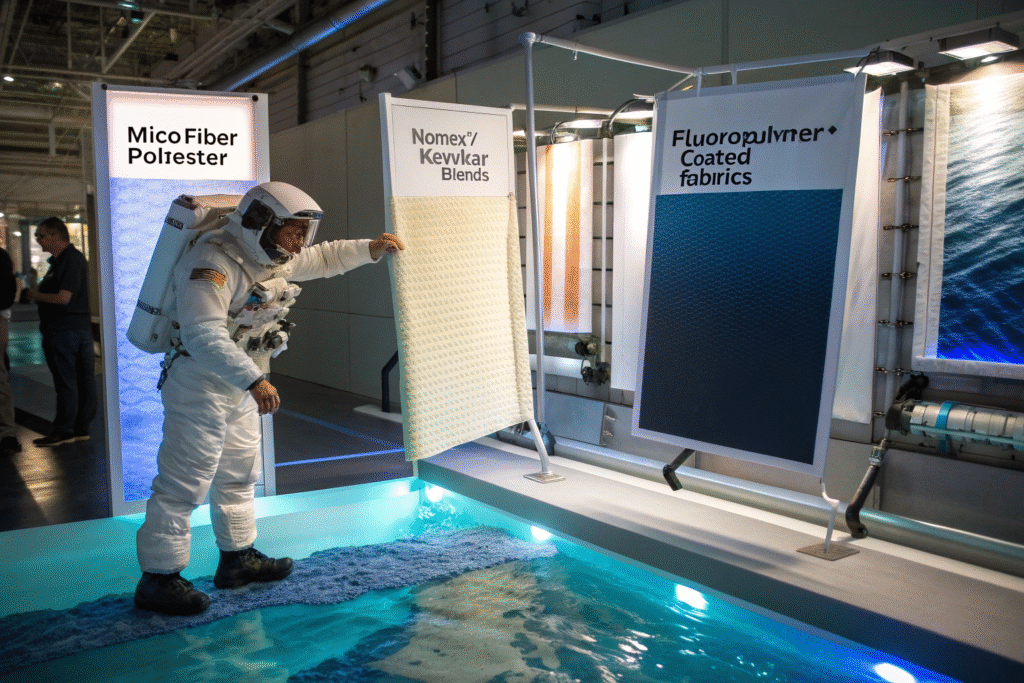

Which Fabrics Are Commonly Used in Space Applications?

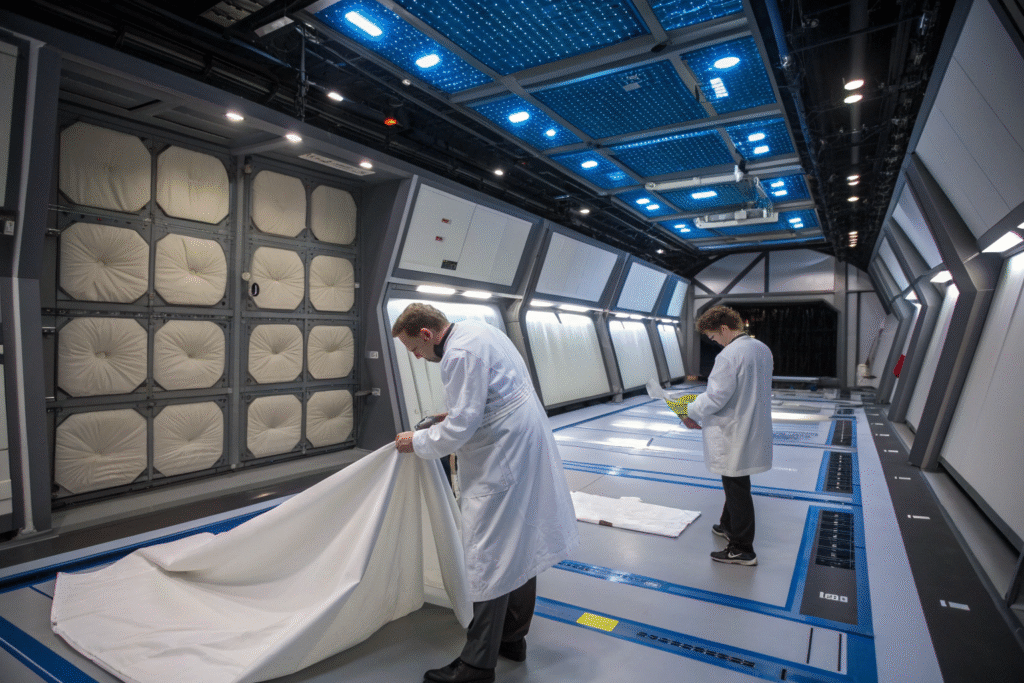

Astronauts already rely on specialized textiles in suits, wipes, and cabin systems. Each material is chosen for its interaction with fluids in microgravity.

Common fabrics include microfiber polyester for absorption, Nomex and Kevlar blends for safety, and fluoropolymer-coated fabrics for repelling water. These materials must also withstand radiation, fire risks, and mechanical wear.

Are Microfiber Fabrics Effective for Absorption?

Microfibers excel at trapping and holding water because of their dense weave and small filament diameter. This is why they are often used in cleaning cloths aboard spacecraft. According to ScienceDirect studies on microfiber absorbency, these fabrics can hold several times their weight in liquid. In zero-gravity, this ensures fluids are absorbed and contained instead of floating around.

Why Use Nomex and Kevlar in Fluid Management?

While not absorbent, Nomex and Kevlar blends are used in areas where fire resistance and structural strength matter. For instance, when combined with fluid-absorbing layers, these fabrics provide safety from electrical shorts or fire hazards. NASA has integrated such textiles into spacesuit layers where moisture, oxygen, and thermal control all intersect.

What Future Innovations Are Being Explored?

Material science continues to push boundaries. New fabrics are being engineered with nano-coatings, smart fibers, and biodegradable properties for sustainable missions.

Researchers are testing fabrics that can actively repel, filter, or even recycle fluids in space. These developments could transform how astronauts manage water, sanitation, and even medical applications during long missions to Mars or beyond.

Can Nanotechnology Improve Fluid Control in Space?

Nanocoatings can change the surface energy of fabrics, making them superhydrophobic or superhydrophilic. A MIT nanotech study demonstrated fabrics that repel nearly all fluids, even oils. Such textiles could prevent contamination in sensitive spacecraft systems.

Are Self-Cleaning Fabrics a Possibility?

Yes. Fabrics with photocatalytic coatings can break down organic matter under UV light, creating self-cleaning properties. This could be revolutionary for long-term missions where laundry is impossible. A study from ACS Publications highlights how titanium dioxide coatings can create fabrics that decompose stains and bacteria when exposed to light.

What Are the Key Challenges in Fabric Development for Space?

Despite progress, there are still limitations. Fabrics must balance absorbency, repellency, weight, durability, and safety.

The biggest challenge is designing textiles that work across multiple functions in unpredictable environments. Engineers are constantly testing trade-offs to make fabrics practical for use in orbit or deep space.

Why Is Multi-Functionality Critical?

Spacecraft have limited storage. Fabrics that can absorb fluids, resist fire, and remain lightweight reduce cargo loads. NASA’s advanced materials research emphasizes multifunctional textiles as a future priority.

Can Fabrics Handle Both Liquid and Vapor Management?

This is where hybrid designs come in. Laminates combining absorbent cores with vapor-permeable membranes can handle both liquid spills and humidity control. An example is Sympatex membranes that block liquid but allow moisture vapor to escape. Such principles could adapt to spacecraft cabins, where humidity and condensation must be carefully managed.

Conclusion

The best fabrics for zero-gravity fluid management are not just about absorbency or repellency. They are carefully engineered to harness capillary action, resist unwanted spread, and adapt to multiple challenges of space travel. From microfiber wipes to nanotech-enhanced textiles, these fabrics are shaping the future of safe and efficient space missions.

As textile producers on Earth, we find inspiration in these innovations. The lessons from space fabrics—lightweight, multifunctional, and sustainable—also guide us in creating advanced materials for fashion, sportswear, and technical industries. If you are looking to explore cutting-edge textiles for your own applications, we welcome you to connect with us at Shanghai Fumao. Reach out to our Business Director Elaine at elaine@fumaoclothing.com to discuss your custom fabric needs.