When businesses overlook safety standards in electrical environments, the risks are far-reaching. Workers face threats of burns, shocks, and even fatalities from arc flashes or direct contact. Employers face lawsuits, downtime, and damaged reputations. The problem grows when companies purchase protective suits that look durable but lack compliance with international safety standards.

NFPA 70E certification is vital because it provides a benchmark for electrical safety apparel, ensuring workers are shielded from arc flash and shock hazards. This certification standard, widely recognized across industries, defines how protective suits are designed, tested, and rated, giving both employers and workers the assurance that the gear can perform when lives are on the line.

Without NFPA 70E, there’s no guarantee of protection. This makes understanding and demanding certification a non-negotiable step for businesses that prioritize safety. Let’s dive deeper into why NFPA 70E-certified electric hazard suits matter so much.

What Does NFPA 70E Certification Really Mean?

NFPA 70E isn’t just a number. It is the National Fire Protection Association’s standard that sets guidelines for protecting workers from electrical hazards like arc flashes and electrical shock. Many companies underestimate the importance of these requirements, assuming all protective clothing provides equal protection.

NFPA 70E certification means the fabric and construction of the suit have been tested against arc flash exposure and meet minimum performance criteria to reduce injury risks.

When a suit carries this certification, it signals that it can withstand specific levels of heat, flame, and energy released during electrical incidents. Without such certification, clothing may ignite, melt, or fail under pressure, leaving workers dangerously exposed.

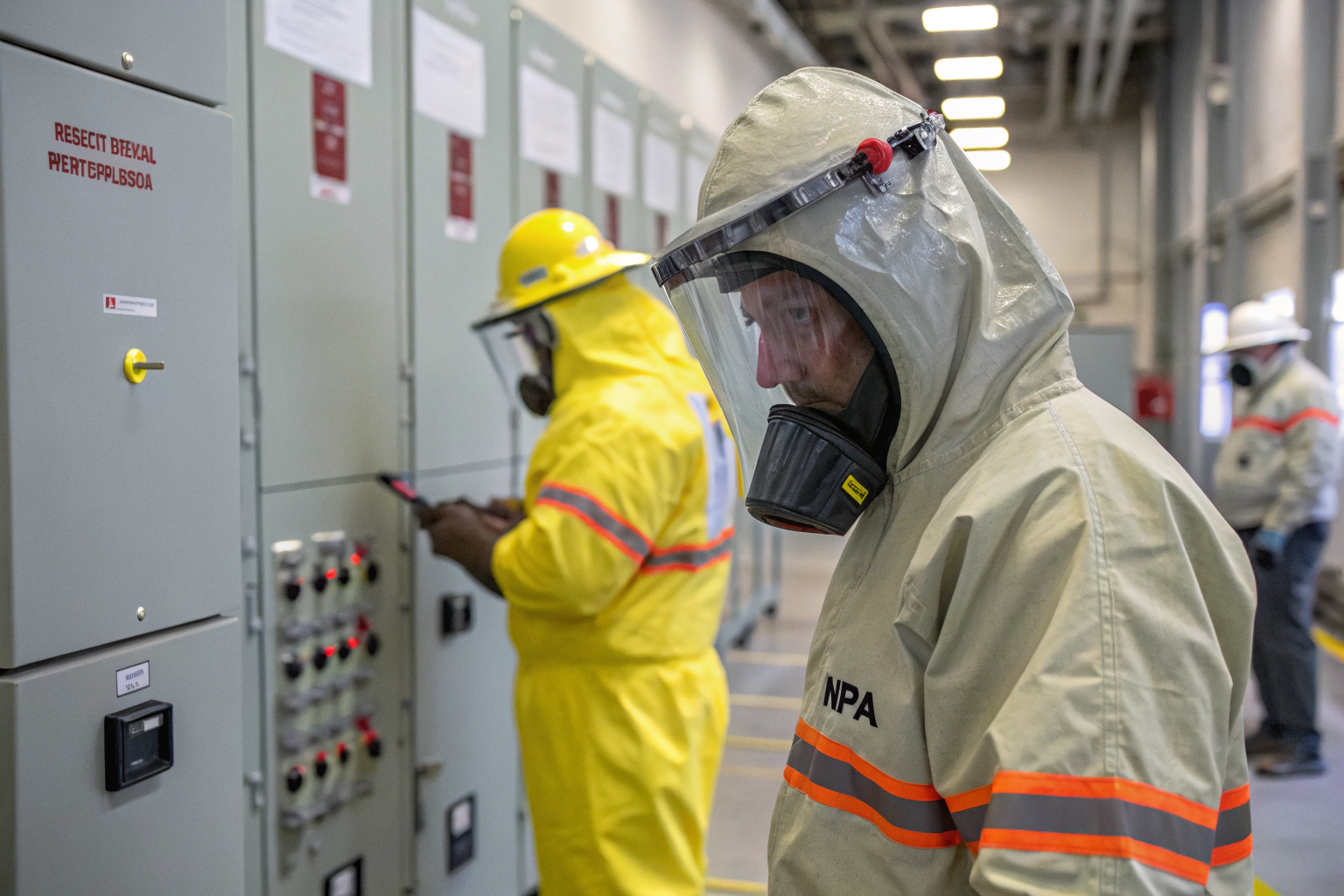

Why Do Workers Need Certified Protection?

Workers face unpredictable conditions, from live electrical panels to high-voltage environments. Certified suits are engineered to minimize harm, ensuring survival and reducing injury severity. According to the NFPA official site, workplace incidents are significantly less severe when protective gear meets these standards. Another reference, OSHA guidelines, also reinforce compliance with NFPA 70E as part of workplace safety obligations.

How Does Certification Influence Employer Liability?

Employers that provide uncertified suits risk non-compliance with OSHA regulations, potential fines, and lawsuits after accidents. Certification not only protects workers but also shields companies legally and financially. For global brands and factories sourcing protective suits, NFPA 70E certification serves as a guarantee of compliance and responsibility.

How Do Arc Flash Ratings Affect Suit Selection?

Choosing an NFPA 70E suit isn’t just about checking a box. Every suit carries an Arc Thermal Performance Value (ATPV), which measures how much heat it can resist before causing second-degree burns. Many buyers overlook this, opting for cheaper options that may fail when needed most.

Arc flash ratings help match the right suit to the specific electrical environment, preventing under-protection or unnecessary overspending.

What Is ATPV and Why Is It Important?

The ATPV rating, expressed in cal/cm², indicates the maximum incident energy the fabric can withstand. For instance, a rating of 8 cal/cm² suits may protect against small electrical tasks, while environments with higher voltage demand suits rated 40 cal/cm² or above. The Electrical Safety Foundation International highlights how proper ATPV ratings drastically reduce burn injuries.

How Do Employers Determine Proper Suit Ratings?

Employers must conduct arc flash hazard analyses as per IEEE standards. These assessments measure potential incident energy in the workplace, guiding the choice of protective clothing. By aligning ATPV ratings with risk levels, businesses ensure neither overprotection that adds cost nor underprotection that endangers lives.

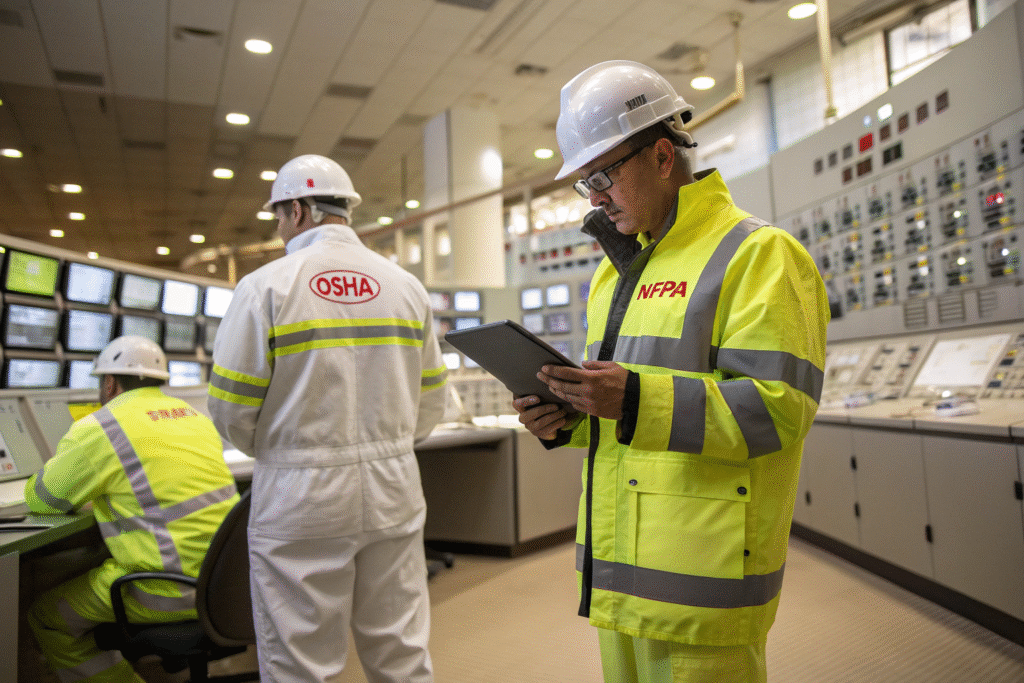

Why Is Compliance With OSHA and NFPA 70E Critical?

Some companies treat compliance as red tape. But in reality, it is the backbone of workplace safety. When OSHA regulations intersect with NFPA 70E standards, the result is a powerful framework that protects both workers and organizations.

Compliance ensures safety, reduces liability, and maintains trust with employees and clients.

What Happens if Businesses Ignore Compliance?

Non-compliance can lead to severe fines, operational shutdowns, and irreparable reputational damage. According to OSHA penalties, violations can cost tens of thousands of dollars per incident. Worse, ignoring compliance puts workers at life-threatening risk.

How Does Compliance Boost Worker Confidence?

When workers know they are wearing NFPA 70E-certified suits, their confidence grows. They feel secure, which improves focus, productivity, and loyalty. Safety-certified gear is not just a requirement—it’s a message that employers value their teams. More companies are now promoting their safety-first approach as part of their brand reputation, gaining trust with partners and customers alike.

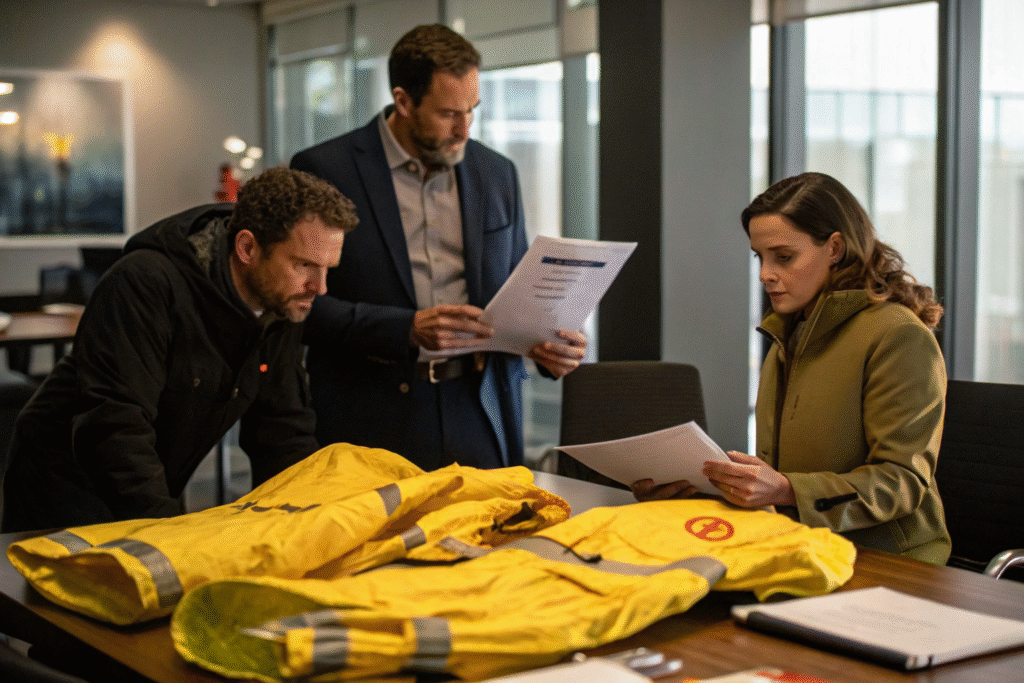

How Can Businesses Ensure Proper NFPA 70E Suit Procurement?

Even when companies want certified suits, the market is full of imitations. Procurement teams often struggle to identify authentic NFPA 70E products.

To ensure safety, businesses must source from trusted manufacturers and demand full certification documentation.

What Questions Should Buyers Ask Suppliers?

Buyers should request test reports, certifications, and fabric specifications before making purchases. Reliable vendors provide transparent documentation, often verified by independent labs like SGS Testing Services. This process ensures that what appears protective on the surface is truly certified at its core.

Why Partner With Experienced Global Suppliers?

Established global suppliers, like those with integrated production, inspection, and logistics systems, guarantee consistency in quality and compliance. They understand international regulations and can support fast, large-scale delivery without compromising standards. Partnering with experienced suppliers reduces risks of counterfeit gear and delays.

Conclusion

NFPA 70E certification is not optional—it is essential. Certified electric hazard suits save lives, reduce injuries, and protect employers from devastating liability. From understanding arc flash ratings to aligning with OSHA compliance, businesses that prioritize certification demonstrate leadership in workplace safety.

If you are considering sourcing NFPA 70E-certified electric hazard suits or other protective fabrics, we at Shanghai Fumao are here to help. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can support your orders with certified, high-quality fabrics and protective solutions.