When sourcing fabrics, every buyer fears one common problem: clothes losing shape, fading colors, or surface damage after dry cleaning. This issue not only frustrates end consumers but also leads to costly complaints and returns for brands. Without reliable standards, fashion labels risk shipping garments that fail in the real world.

The ISO 3175-4 standard provides an internationally recognized benchmark for assessing a fabric’s resistance to professional dry cleaning. It ensures that garments retain appearance, durability, and performance even after repeated cleaning cycles. For suppliers and buyers alike, compliance means fewer risks, stronger trust, and higher customer satisfaction.

In today’s textile supply chain, efficiency and safety are no longer enough—quality assurance must extend to aftercare. ISO 3175-4 bridges the gap between production and consumer use, giving brands confidence that their fabrics will withstand dry cleaning processes in global markets.

Key Requirements of ISO 3175-4

The ISO 3175-4 standard outlines specific conditions that fabrics must meet to be considered resistant to dry cleaning solvents and procedures.

ISO 3175-4 specifies the testing of textile fabrics using perchloroethylene and alternative solvents, simulating professional dry cleaning conditions to assess fabric stability and appearance.

What solvents are used in ISO 3175-4 testing?

Fabrics are typically exposed to perchloroethylene (PCE), a widely used solvent in dry cleaning. Alternative solvents such as hydrocarbon and siloxane are also included in testing. According to Textile Exchange, solvent selection influences shrinkage, color fastness, and fiber durability. For eco-conscious markets, many brands seek alternatives to PCE due to environmental concerns.

How are fabrics evaluated during testing?

The testing process checks for dimensional stability, color change, seam puckering, and texture alterations. Independent laboratories like Intertek provide third-party verification to ensure fabrics meet the ISO benchmark. Results include detailed reports on shrinkage percentages, color rating scales, and resistance to deformation.

Benefits for Fashion Brands and Buyers

The ISO 3175-4 standard offers significant benefits for global buyers and brands looking to minimize risks and maximize consumer satisfaction.

By requiring suppliers to meet ISO 3175-4, buyers gain confidence that fabrics will maintain quality after cleaning, reducing claims, strengthening brand trust, and supporting sustainability goals.

Why is ISO 3175-4 important for luxury and premium brands?

Luxury brands cannot afford customer complaints about color fading or fabric deformation. Compliance with ISO 3175-4 helps these companies ensure long-term wearability. As SGS notes, rigorous aftercare testing is essential for premium fabrics like silk and wool. Buyers of high-end garments prefer suppliers who invest in certified testing to maintain their brand reputation.

How does it reduce costs for global buyers?

Every return or complaint costs brands money and damages reputation. By working with suppliers compliant with ISO 3175-4, buyers reduce rework, waste, and logistic issues. In markets like the U.S., where FTC care labeling rules require clear care instructions, certified fabrics help ensure compliance and reduce legal risks.

ISO 3175-4 vs Other Textile Standards

ISO 3175-4 is one of many standards governing fabric durability, but it focuses specifically on dry cleaning resistance.

**Unlike ISO 6330 (domestic washing) or ISO 105 (color fastness), ISO 3175-4 replicates professional dry cleaning conditions,

How does ISO 3175-4 differ from ISO 6330 washing tests?

ISO 6330 tests machine washing performance, simulating consumer laundry. However, fabrics that perform well in washing may still fail in dry cleaning. OEKO-TEX® explains that dry cleaning solvents interact differently with dyes and finishes, meaning a separate standard is essential.

Why is ISO 3175-4 preferred for export markets?

Export buyers, especially in Europe and North America, demand compliance with dry cleaning standards to avoid post-sale problems. Certification assures them that garments will meet both consumer expectations and retail quality standards. As Bureau Veritas emphasizes, compliance reduces border inspection risks and delays.

How to Ensure Compliance with ISO 3175-4

Meeting ISO 3175-4 is not just about passing a test—it requires a systematic approach across sourcing, production, and quality control.

The best way to ensure compliance is by working with certified suppliers who integrate ISO 3175-4 testing into their production cycle, supported by third-party labs and transparent QC reports.

What role do suppliers play in compliance?

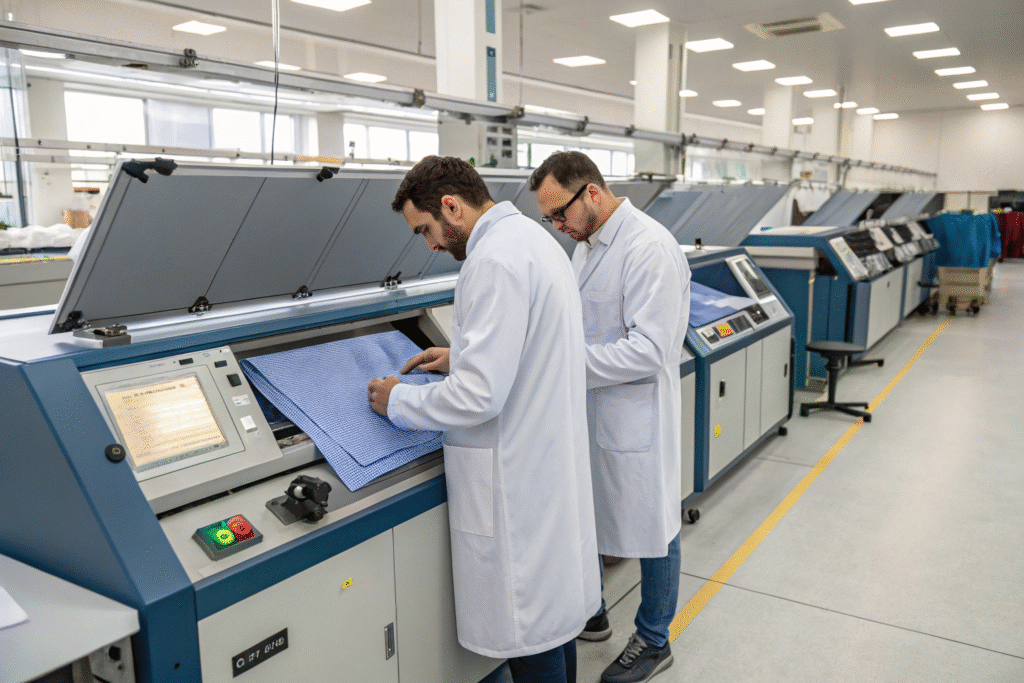

Suppliers must test fabrics during development and production to avoid late-stage failures. As seen on AATCC resources, proactive testing saves time and ensures bulk orders are consistent. Reliable suppliers maintain ISO-compliant labs or partner with accredited agencies to guarantee accuracy.

How can buyers verify compliance before placing orders?

Buyers should request test reports, fabric data sheets, and certification records from suppliers. Independent verification from labs like TÜV SÜD can provide additional assurance. Clear documentation protects buyers from disputes, strengthens supply chain transparency, and ensures smooth international logistics.

Conclusion

ISO 3175-4 is critical for ensuring fabric durability during dry cleaning, a process many consumers rely on for premium garments. By adopting this standard, suppliers and buyers reduce risks, enhance brand value, and strengthen customer trust across global markets.

If you are seeking fabrics that comply with ISO 3175-4 and other international standards, our company Shanghai Fumao can provide comprehensive solutions. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your next fabric order with confidence.