When you are sourcing biodegradable stent graft vascular textiles, you may feel overwhelmed. The industry is complex, medical regulations are strict, and material performance is critical. If you are a buyer or medical device developer, you face a painful problem: the risk of choosing the wrong supplier may delay your project for years and increase costs.

The best way to source biodegradable stent graft vascular textiles is to focus on three things: trusted material suppliers, proven textile engineering technologies, and a clear regulatory and logistics roadmap. When these three elements align, you can reduce risks, ensure safety, and accelerate your time to market.

This article will show you how to identify the right materials, connect with capable partners, and manage global regulations so you can successfully source biodegradable stent graft vascular textiles without wasting time and resources.

What Are the Best Materials for Biodegradable Vascular Textiles?

When sourcing, many buyers get confused about which materials are suitable. They worry about durability, safety, and cost. This is because the wrong material may degrade too fast, or not at all, causing medical risks.

The best biodegradable vascular textiles are made from absorbable polymers such as PLA, PGA, PLCL, and silk-based biomaterials, or bioresorbable metals such as magnesium and zinc alloys. These materials are proven safe and effective in vascular applications.

Why Are Biodegradable Polymers Popular?

Polymers like polylactic acid (PLA) and polyglycolic acid (PGA) are widely used in medical textiles. They have excellent biocompatibility and predictable degradation rates. Many researchers also use polycaprolactone (PCL) blends because they balance flexibility and strength. In fact, the FDA has approved several medical implants using these polymers.

Can Natural Fibers Work in Stent Grafts?

Natural fibers such as silk fibroin are gaining attention. Silk is strong, elastic, and naturally compatible with human tissue. Researchers at SpringerLink confirm silk-based vascular scaffolds perform well in long-term studies. Bamboo-derived viscose is also being tested, but silk remains the leader in natural-based vascular biomaterials.

Which Textile Techniques Ensure Performance?

Buyers often ask: if the right material is chosen, is that enough? The answer is no. The textile engineering method determines how the graft performs under blood pressure.

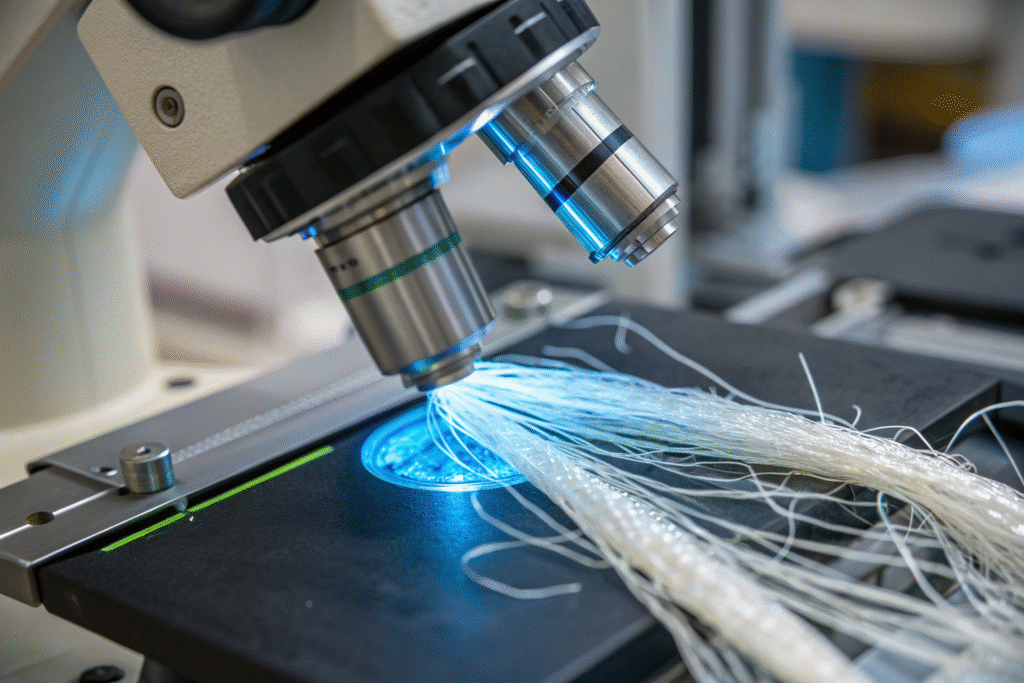

Electrospinning, knitting, and weaving are the three main techniques used to create vascular textiles. Electrospinning is the most advanced, producing nanofiber scaffolds that mimic natural vessels.

Is Electrospinning the Future of Vascular Textiles?

Electrospinning creates very fine fibers that form porous scaffolds, similar to natural extracellular matrix. According to MDPI, these scaffolds allow cells to grow and integrate with the graft. Many European and U.S. labs already use electrospinning to make biodegradable vascular patches.

Do Knitting and Weaving Still Matter?

Yes. While electrospinning is popular, knitted and woven grafts offer durability and higher burst strength. Knitted textiles are elastic and adapt to blood flow, while woven structures are stable and resist leakage. A Textile Tech Source report shows many manufacturers combine weaving with polymer coatings to balance strength and bioactivity.

Where to Find Trusted Suppliers and Partners?

Even if you know the materials and techniques, sourcing is hard without the right partners. Many companies claim to offer biodegradable solutions, but few can deliver medical-grade quality.

The best way to find suppliers is to target polymer producers of medical-grade PLA or magnesium, textile labs with implantable expertise, and OEM device manufacturers with regulatory track records.

How to Evaluate a Supplier’s Capability?

Ask for ISO 13485 certification, which is the global quality standard for medical device manufacturing. Also request test data for tensile strength, burst pressure, and degradation rate. Reliable companies such as Evonik and Corbion supply biodegradable polymers for implants.

Should You Work With Research Labs?

Yes. Partnering with textile research labs helps accelerate innovation. For example, the National University of Singapore and many European labs are leaders in silk and polymer vascular scaffolds. Such collaborations bring access to cutting-edge techniques like nanofiber composites.

How to Manage Supply Chain and Regulations?

Many buyers worry about tariffs, shipping delays, and clinical approval. These are valid concerns because the supply chain for medical textiles is global and highly regulated.

To succeed, you must diversify sourcing, understand regional regulatory pathways, and plan long-term logistics.

What Are the Key Regulatory Challenges?

In the U.S., the FDA demands long-term clinical data, often delaying biodegradable graft approvals. In Europe, the MDR framework allows faster approval, but requires strict monitoring. In China, the NMPA has a faster “Innovative Medical Device” route, which helps local companies enter the market quickly.

How Can You Reduce Supply Risks?

Tariffs on medical-grade polymers have increased costs in the U.S. To reduce risk, companies diversify sourcing between Europe and Asia. Logistics hubs in Singapore and Hong Kong are also used to speed up shipping. Reports from Mordor Intelligence suggest most successful firms rely on multiple partners in different regions.

Conclusion

Sourcing biodegradable stent graft vascular textiles is not just about finding a supplier. It requires deep knowledge of materials, mastery of textile techniques, trusted global partners, and awareness of strict regulatory landscapes. By focusing on proven biodegradable polymers, advanced textile methods such as electrospinning, and building partnerships with certified suppliers, you can achieve safer and more reliable vascular graft solutions.

If you are looking for a reliable sourcing partner with a proven record in textile development and supply chain management, contact our team at Shanghai Fumao. You can reach our Business Director Elaine at elaine@fumaoclothing.com to start your project today.