In the global textile industry, heat resistance is more than a selling point—it is a vital measure of safety, performance, and compliance. For buyers in the U.S., Europe, and other regulated markets, choosing fabrics that fail to meet international safety standards can lead to rejected shipments, costly recalls, or even legal consequences. One of the most important standards in this domain is ISO 17493, which specifies a method for testing the heat resistance of protective clothing materials.

ISO 17493 provides a reliable, repeatable way to determine whether fabrics will maintain their protective qualities under high-temperature exposure. At Fumao Fabric, we integrate this standard into our design, production, and quality control workflows to ensure every fabric not only meets the required safety benchmarks but also aligns with buyers’ aesthetic and functional needs.

Understanding ISO 17493 Heat Resistance Standards

ISO 17493 is an internationally recognized standard that defines how to test protective clothing materials for their ability to resist heat. This method is widely used for fabrics designed for heat and flame protection in high-risk industries such as firefighting, foundry work, welding, and certain manufacturing sectors.

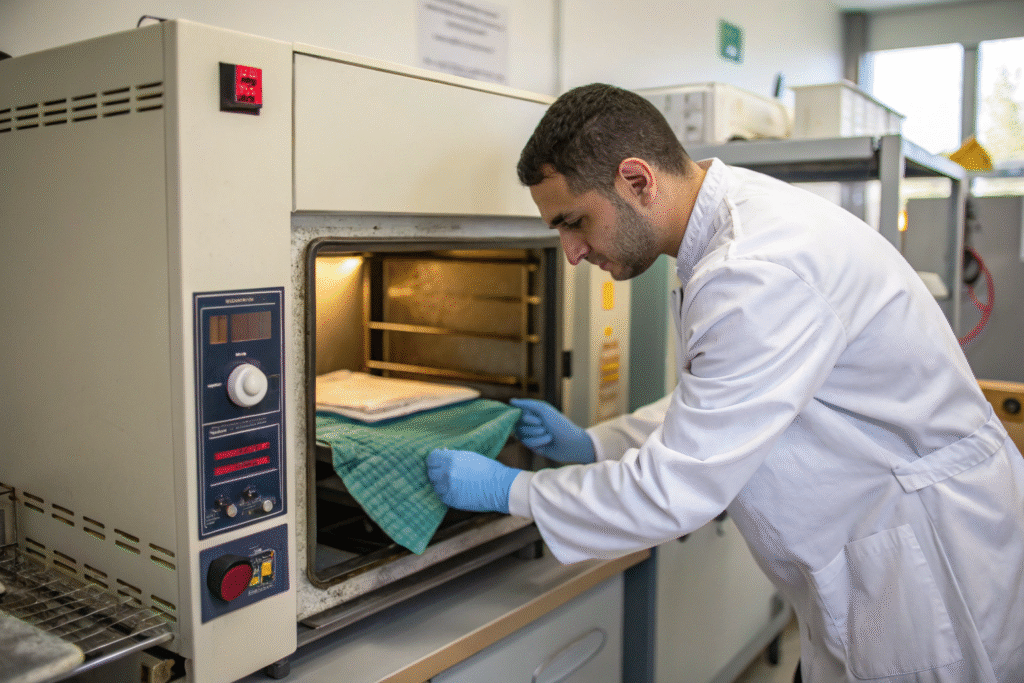

The process involves conditioning the fabric samples, heating an oven to a precise temperature—often 180°C—and placing the samples inside for a set period, usually 5 minutes. After exposure, the fabrics are examined for shrinkage, melting, ignition, or any visible degradation. A pass means the fabric retains structural integrity and protective performance.

What Are the Key Procedures in ISO 17493 Testing?

- Condition samples under controlled humidity and temperature.

- Preheat oven to the exact required test temperature.

- Expose samples for the set duration.

- Evaluate results for changes in size, surface, or integrity.

For detailed procedures, visit the ISO official page or see SGS Textile Testing for practical testing insights.

Why Is This Testing Method Trusted Globally?

This method’s credibility comes from its reproducibility and objectivity. It removes guesswork, ensuring materials meet international safety laws such as those defined by the European Committee for Standardization and supported by global buyers. Reliable results build trust between suppliers and procurement teams.

Benefits of ISO 17493 Compliance for Textile Buyers

For global textile buyers—especially in the U.S.—ISO 17493 compliance is not just about ticking a safety checkbox. It is a competitive advantage that can protect brand reputation, improve customer trust, and streamline customs clearance in strict markets.

How Does It Reduce Procurement Risks?

Non-compliant materials risk shipment rejections, re-testing delays, or safety failures during use. U.S. buyers in the PPE sector must meet OSHA standards. Choosing ISO 17493-compliant fabrics from the start eliminates many of these risks, saving both time and money.

You can also reference the National Fire Protection Association guidelines to understand how these safety requirements align with fabric performance standards.

How Does It Build Buyer Confidence?

Buyers gain confidence when suppliers provide third-party certified test reports. ISO 17493 compliance is a clear signal of professionalism and quality assurance. For a model of transparent textile testing, see Bureau Veritas Textile Services.

Integrating ISO 17493 in Fabric Development

At Fumao Fabric, ISO 17493 testing is a built-in step of our product development. We apply it early—before bulk production—so clients receive only fabrics that meet both safety and style expectations.

How Do We Guarantee Consistency?

We run in-house pre-tests using calibrated equipment, then send samples to CNAS-accredited labs for certification. This double-check ensures reliability before shipping to clients. You can learn more about accredited lab testing from the China National Accreditation Service for Conformity Assessment.

How Does It Encourage Innovation?

Once a fabric meets ISO 17493, our R&D team can explore blends of safety and design, like flame-retardant denim or stylish industrial uniforms. For insights into technical textiles, see Textile World Innovation.

Choosing the Right Supplier for Heat-Resistant Fabrics

Selecting a supplier with ISO 17493 capabilities is vital for both safety compliance and smooth logistics.

What Criteria Should You Use?

- Access to internationally recognized labs.

- In-house pre-testing capability.

- Clear documentation for each order.

The American Apparel & Footwear Association Sourcing Guidelines offer useful criteria for supplier evaluation.

How Can Fumao Fabric Support You?

We combine ISO 17493 compliance, one-stop customization, and global logistics. See our certified fabrics at Fumao Fabric Official Site to explore ready-to-order and custom development options.

Conclusion

ISO 17493 is more than a laboratory test—it is a market entry ticket for heat-resistant fabrics in regulated industries. For buyers, it ensures safety, transparency, and reliability. For manufacturers, it represents a commitment to quality and professionalism.

If you want to source ISO 17493-compliant fabrics with confidence, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let’s create fabrics that meet your functional, safety, and aesthetic goals.