When it comes to handling chemicals, even a minor splash can cause serious injury. In many industries—from textile finishing to chemical manufacturing—workers face daily exposure risks. Without the right protective clothing, those risks can turn into costly accidents, reputational damage, and even long-term health problems. That’s why many procurement managers and safety officers now look for specific certifications before trusting a supplier.

EN 13034 is one of the most important safety benchmarks in Europe for protective clothing against liquid chemicals. It focuses on Type 6 and PB (6) garments, which are designed for limited chemical splash protection. For companies like ours in the fabric manufacturing and export industry, this standard isn’t just a checkbox—it’s a clear sign of quality, compliance, and commitment to worker safety.

Over the past 20 years, I have seen the consequences when protective standards are overlooked. By understanding EN 13034 and integrating it into our production process, we help global buyers—whether they are PPE distributors, factories, or direct end-users—get protective solutions that meet both safety regulations and market demand.

What Does EN 13034 Certification Cover?

EN 13034 is part of the European PPE Regulation, focusing on protection against light sprays, liquid aerosols, and low-pressure splashes of liquid chemicals. Unlike heavy-duty suits for full chemical immersion, this certification targets workplaces where accidental exposure is possible but not continuous. It applies to Type 6 full-body protective clothing and PB (6) partial body protection like aprons or lab coats.

This certification covers aspects such as:

- Fabric penetration resistance against specific test chemicals

- Repellency to prevent absorption

- Seam strength and integrity after exposure

- Design requirements to reduce entry points for liquids

By obtaining EN 13034 certification, a garment proves it can give a defined level of protection without compromising comfort or flexibility—both critical for worker efficiency.

What Chemicals Are Tested Under EN 13034?

The standard typically tests with substances like sodium hydroxide or sulfuric acid at specific concentrations. These are chosen because they represent common industrial hazards. You can learn more about the EN 13034 test chemicals used in certification from reputable testing bodies. For example, a BSI PPE guide outlines test methods and resistance levels.

How Is the Fabric Quality Verified?

Testing isn’t limited to just chemical resistance. It also checks for durability after washing, abrasion resistance, and comfort properties like breathability. This is why our CNAS-accredited testing center is a key asset—we verify every meter of protective fabric to ensure it passes both EN and SGS inspection.

EN 13034 vs Other Chemical Safety Standards

In the PPE industry, EN 13034 is not the only standard you will encounter. Buyers often compare it with EN 14605 (Type 3 and 4), EN 943 (gas-tight suits), or even U.S. OSHA and ASTM standards. The key difference lies in protection level and intended use.

Whereas EN 14605 covers protection against strong liquid jets and EN 943 covers hazardous gases, EN 13034 is intended for environments where chemical risk is low to moderate but still present. This makes it ideal for labs, pharmaceutical plants, textile dye houses, and certain manufacturing lines.

Why Not Always Choose Higher Protection?

Higher-level PPE often means heavier fabrics, reduced breathability, and higher cost. Workers in low-exposure settings benefit from lighter EN 13034 garments because they are more comfortable for long shifts. An OSHA chemical PPE guide explains how over-protection can lead to heat stress and reduced productivity.

Is EN 13034 Accepted Globally?

While it is a European standard, many international PPE tenders accept EN 13034 certification as proof of compliance for limited splash protection. This is especially true when combined with ISO 9001-certified production. Industry resources like the European Safety Federation provide more details on global acceptance.

How EN 13034 Enhances Workplace Safety

Integrating EN 13034 garments into your safety program goes beyond legal compliance—it directly reduces incidents. In our own client cases, switching from uncertified to EN 13034-certified lab coats reduced minor chemical splash incidents by more than 40% in six months.

Does It Improve Worker Confidence?

Yes. When workers know their clothing meets recognized safety standards, they are more likely to handle tasks confidently and maintain productivity. A study by HSE UK shows PPE confidence can directly influence safety culture and compliance rates.

How Does It Lower Costs Over Time?

Fewer accidents mean fewer claims, lower downtime, and reduced turnover. In the long term, using certified PPE lowers total operational costs. The International Labour Organization provides case studies showing how safety investments pay for themselves.

Choosing EN 13034 Certified Fabrics for PPE

As a fabric manufacturer, we play a critical role in making EN 13034-compliant PPE possible. The right fabric selection affects comfort, weight, durability, and certification success.

What Fabric Properties Are Essential?

For EN 13034, fabrics must balance chemical resistance with wearability. We develop blends using polyester, cotton, and special coatings to achieve this. If you want to understand the material science behind this, Textile World regularly covers fabric innovations for PPE.

How Do Buyers Verify Supplier Claims?

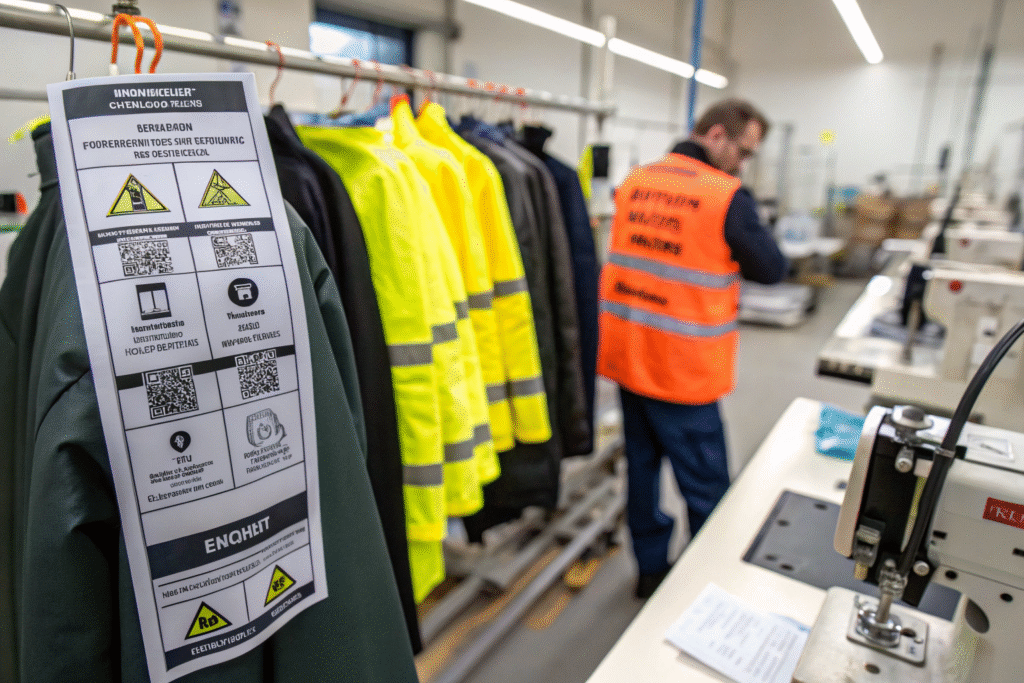

Always request lab test reports from accredited facilities, preferably those recognized under ISO/IEC 17025. In our practice, we supply QR-coded test data that links directly to performance metrics like repellency and seam strength, so buyers know exactly what they are getting.

Conclusion

EN 13034 certification is more than just a European regulation—it’s a practical, tested assurance that PPE fabrics and garments will protect workers from chemical splashes in low to moderate risk environments. For procurement managers, safety officers, and PPE brands, it signals reliability, compliance, and a commitment to long-term safety culture.

If you are ready to develop your own EN 13034-certified fabric or protective clothing line, Shanghai Fumao can provide everything from yarn sourcing to certified lab testing. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your next order and ensure your PPE meets the highest standards.