Self-healing polyurethane coated fabrics are not just a trend—they are redefining the textile industry. In an era where customers demand durability, functionality, and sustainability, these innovative fabrics are capturing attention from outdoor gear makers, military suppliers, and high-performance apparel brands. By integrating a polyurethane coating that can "heal" minor cuts or abrasions when exposed to heat or pressure, manufacturers are offering a new standard of resilience.

At Fumao Fabric, we recognize that global buyers are increasingly prioritizing long-term performance over short-term cost savings. Self-healing technology ensures that garments and equipment last longer, withstand harsher conditions, and reduce the need for constant replacement—directly impacting cost efficiency and sustainability goals.

The combination of polyurethane coating and advanced weaving techniques means this fabric is not only strong but also versatile. It adapts to different industries, from protective workwear to luxury fashion accessories. Let’s explore why more and more global buyers—especially in the U.S., Europe, and Southeast Asia—are choosing self-healing polyurethane coated fabrics.

Enhanced Durability for Harsh Environments

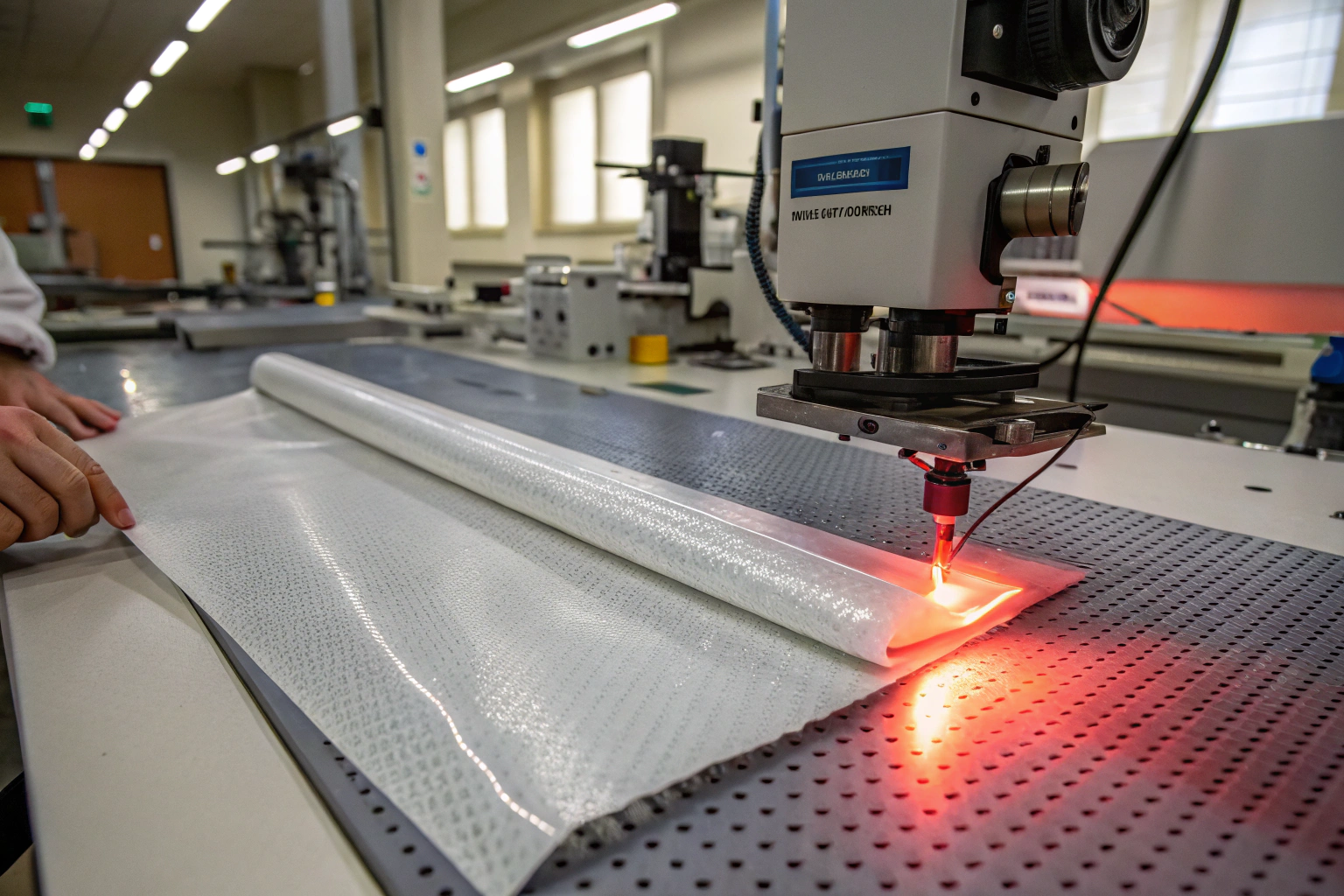

Outdoor conditions can be unpredictable and unforgiving. Traditional fabrics can fray, tear, or degrade quickly when exposed to rough handling, moisture, or sharp edges. This is where self-healing polyurethane coated fabrics make a remarkable difference. The coating acts as a flexible armor, and when minor scratches occur, the material can recover its surface integrity through a heat-activation process.

These fabrics have been tested to meet stringent international standards, including ISO 12947 Martindale abrasion resistance and ASTM D3884-09 Taber abrasion tests. This makes them ideal for military uniforms, tactical gear, and outdoor equipment that require consistent performance in the field.

How Does Self-Healing Technology Work?

When the coated surface is scratched, the polyurethane molecules realign and close the gap upon exposure to warmth, either from body heat or an external source like a hair dryer. This is similar to how certain synthetic rubbers recover from deformation, but with a much faster response time. For end-users, this means the product looks and performs like new for a longer period.

Which Industries Benefit Most?

Industries such as military, outdoor adventure sports (North Face style applications), marine equipment manufacturing, and protective workwear are adopting self-healing fabrics because they reduce downtime, replacement costs, and waste. For buyers, the ROI is clear—fewer replacements and higher customer satisfaction.

Superior Waterproofing and Weather Resistance

Water resistance is one of the main selling points of polyurethane coatings. When combined with self-healing capabilities, the result is a fabric that not only resists water penetration but also restores its protective layer after damage. This ensures consistent performance in challenging environments.

Compared to traditional waterproof coatings, polyurethane offers better elasticity, meaning the waterproof layer is less likely to crack or peel over time. Tests such as AATCC 22 Spray Test and ISO 811 Hydrostatic Pressure Test confirm that self-healing polyurethane coated fabrics maintain superior performance after repeated folding and flexing.

Why Waterproofing Matters in Self-Healing Fabrics?

If a waterproof layer is damaged, even a small scratch can lead to water leakage. Self-healing technology prevents this by quickly restoring the coating, keeping the fabric waterproof and functional. This feature is especially valuable for camping tents (REI Co-op grade) and marine sails.

Key Benefits for Apparel and Gear

- Long-lasting waterproof barrier

- Resistance to UV degradation

- Maintained flexibility in cold conditions

For buyers looking to differentiate their products, self-healing waterproof fabrics offer a high-tech selling point that aligns with premium market positioning.

Sustainable and Cost-Effective Production

Sustainability is no longer optional in the textile industry—it’s a business requirement. Self-healing fabrics contribute to environmental goals by reducing waste from damaged goods and extending the lifecycle of products. When fewer items are discarded, fewer resources are consumed in replacement production.

At Fumao Fabric, we integrate this technology with eco-friendly production methods, including low-VOC polyurethane formulations and energy-efficient coating processes. These practices comply with OEKO-TEX® Standard 100 and REACH regulations, ensuring safety and sustainability.

How Does It Save Costs for Buyers?

While the initial price may be slightly higher than conventional coated fabrics, the extended service life offsets this investment. Large buyers—especially those supplying uniforms or high-use equipment—can cut replacement rates by up to 40%.

Aligning With Global Green Initiatives

Sourcing sustainable materials also positions brands to align with UN Sustainable Development Goals and appeal to eco-conscious consumers, a growing segment in both the U.S. and EU markets.

Versatility Across Applications

Self-healing polyurethane coated fabrics are not confined to one niche. They perform well across multiple applications, from heavy-duty gear to fashion accessories. This adaptability makes them a strategic choice for buyers aiming to serve different markets with a single material specification.

For instance, the same fabric could be used for a high-performance rain jacket (Arc'teryx level), a protective tool bag, or an industrial tent cover. This cross-functionality simplifies sourcing, reduces inventory complexity, and streamlines supply chain management.

Can It Work in Luxury Fashion?

Yes. With the right finish, self-healing coatings can be applied to delicate fabrics like silk blends, creating luxury items with hidden durability. This opens opportunities for premium handbags, high-end outerwear, and even designer travel gear.

What About Technical and Industrial Uses?

Beyond consumer goods, self-healing polyurethane coated fabrics are being tested in aerospace and automotive interiors, where long-term durability is critical. The ability to maintain both aesthetic quality and functional integrity makes it highly valuable for industrial clients.

Conclusion

Self-healing polyurethane coated fabrics combine durability, waterproofing, sustainability, and versatility into a single advanced textile solution. For buyers in industries ranging from outdoor gear to luxury fashion, this means a competitive edge, lower lifetime costs, and a stronger sustainability profile.

If you are ready to integrate self-healing polyurethane coated fabrics into your product line, we at Shanghai Fumao are here to help. Contact our Business Director Elaine at elaine@fumaoclothing.com to start developing your custom fabric order today.