Shape Memory Alloy (SMA) integrated smart textiles are no longer a futuristic concept—they’re here, shaping the way fashion, sportswear, and medical textiles perform in the real world. But if you’re a brand, a fabric buyer, or a startup founder, knowing where to source these advanced materials can feel overwhelming. I’ve been in the textile manufacturing and export business for over 20 years, and I’ve seen how sourcing the right SMA-integrated fabrics can make or break a product launch.

The truth is, you don’t need to reinvent the wheel. The best sources already exist, but you need to know how to identify them, vet them, and build a partnership that guarantees both quality and supply chain efficiency.

In this guide, I’ll share exactly where to find SMA integrated smart textiles, how to judge quality, the industries adopting them fastest, and whether they’re worth your investment.

Best Global Sources for SMA Smart Textiles

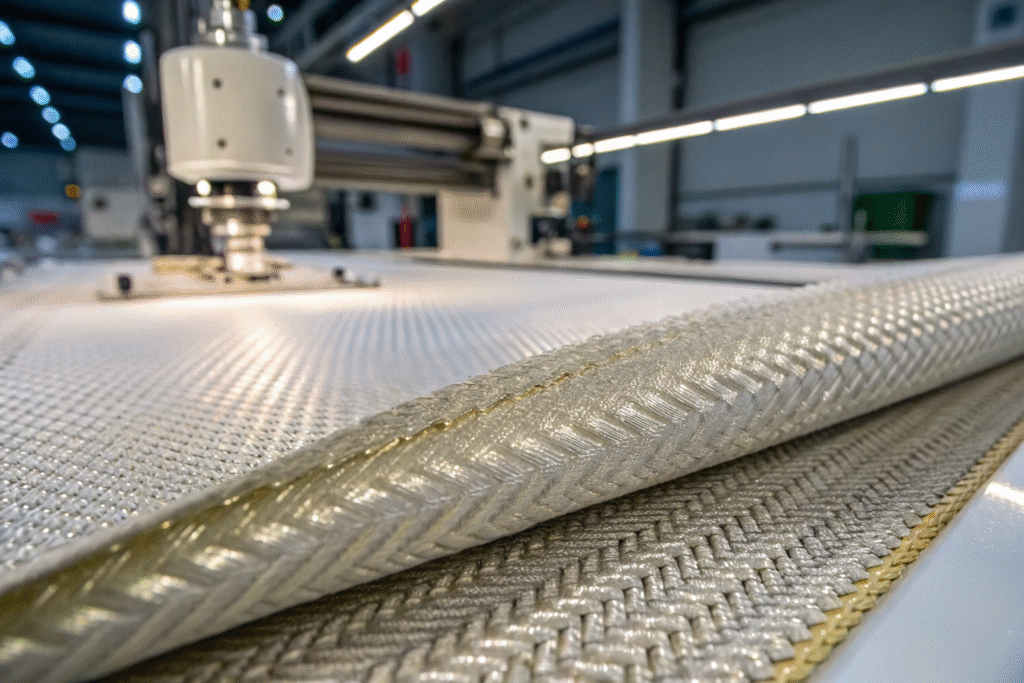

Finding Shape Memory Alloy integrated textiles starts with understanding the global sourcing hubs that dominate production and innovation. SMA fabrics require specialized weaving, knitting, or embedding techniques, so not every textile mill is equipped to make them. The right supplier must have both technical capacity and commercial reliability.

Which countries lead SMA textile production?

China, Japan, and South Korea dominate in SMA textile innovation. China, particularly Keqiao, offers the world’s largest textile cluster with integrated weaving, dyeing, and finishing capabilities. Japan focuses on high-precision SMA wire manufacturing, while South Korea leads in high-performance sportswear applications. European producers, especially in Germany and Italy, excel in technical textile R&D for automotive and medical use.

How to locate trusted suppliers online?

You can start with verified B2B marketplaces like Alibaba and Global Sources, but for SMA textiles, trade fairs like Techtextil (Germany) and Première Vision (France) give you hands-on inspection opportunities. Working with a certified exporter ensures compliance with safety and performance standards.

How to Choose High-Quality Shape Memory Fabrics?

Choosing high-quality SMA fabrics means focusing on material authenticity, integration method, and performance testing. Poorly integrated SMA wires can break, corrode, or fail under repeated stress.

What certifications matter most?

Look for ISO 9001 for quality management and OEKO-TEX Standard 100 for fabric safety. If you’re importing to the U.S., make sure suppliers meet ASTM International performance standards. European buyers often require REACH compliance to avoid restricted substances.

How to verify supplier claims?

Request third-party lab test reports from agencies like SGS or ITS. Ask for sample swatches and test them for recovery time, deformation resistance, and comfort. For SMA textiles, the actuation temperature (often between 30–45°C) is crucial—too high, and it becomes unusable in apparel.

Top Applications of SMA in Modern Apparel

SMA smart textiles aren’t just for tech enthusiasts—they’re redefining how clothing reacts to environmental changes.

How is SMA used in sportswear?

Brands are integrating SMA into jackets and shoes for adaptive fit technology. For example, SMA laces in sneakers tighten automatically when heated by body temperature. Sportswear makers in South Korea lead in this segment, offering apparel that adjusts insulation levels in real time.

What role does SMA play in medical textiles?

In the medical sector, SMA fabrics are used in compression garments, adaptive casts, and rehabilitation aids. Hospitals working with suppliers like Medline source SMA-based devices for patient comfort and improved mobility. This is an expanding market in both North America and Europe.

Are SMA Integrated Textiles Worth the Investment?

The upfront cost of SMA textiles is higher than conventional fabrics, but the long-term benefits can outweigh the price if applied strategically.

What’s the ROI for brands?

When used in premium products, SMA textiles create unique selling points that justify higher retail prices. Outdoor gear brands and medical textile companies report repeat customer rates above industry averages after introducing SMA-based products. Data from Statista shows smart textile revenue growing at 20% CAGR.

How to manage sourcing risks?

Work with suppliers offering flexible MOQs (minimum order quantities) and clear after-sales support. Signing long-term agreements with reputable SMA producers in China or Europe helps stabilize pricing and supply consistency.

Conclusion

Shape Memory Alloy integrated smart textiles are the next leap in functional fashion and technical apparel. Knowing where to find them, how to judge their quality, and which industries adopt them fastest gives you an edge in a competitive market. From Keqiao’s large-scale production hubs to Europe’s advanced R&D centers, opportunities are global and growing.

If you’re ready to develop SMA-integrated fabric products, we at Shanghai Fumao can help. With full-scale weaving, finishing, and export capabilities, plus CNAS-certified testing, we ensure quality and reliability for every shipment. You can reach our Business Director, Elaine, at elaine@fumaoclothing.com to start your custom project today.