In the world of acoustic engineering, fabric is not just decoration—it can be the heart of how sound is controlled, shaped, or absorbed. As a fabric manufacturer based in Keqiao, I have spent years working with designers, engineers, and architects who needed fabrics that do more than look good. Acoustic metamaterials are a prime example of where textiles meet science, and the choice of the right fabric can change the performance of an entire space.

Acoustic metamaterials rely on precise material design to manipulate sound in ways conventional materials cannot. Choosing the right fabric means balancing density, porosity, and durability, while also ensuring it integrates seamlessly into the product or environment. This is not just about muffling noise—it's about shaping sound for clarity, comfort, and function.

When we guide clients—whether they are creating recording studios, open-plan offices, or public installations—we focus on matching their performance requirements with fabrics that deliver on absorption, diffusion, and aesthetic integration. Let’s look at the key questions you might have when selecting the best fabrics for acoustic metamaterials.

How Do Acoustic Metamaterials Work?

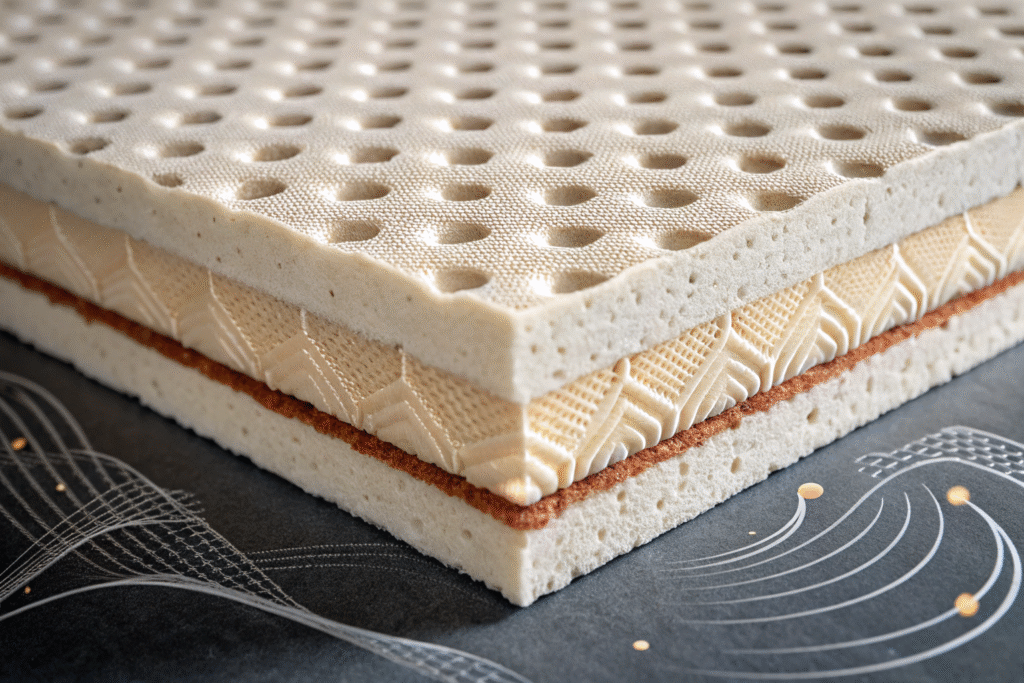

Acoustic metamaterials are engineered to control sound waves beyond the capabilities of standard materials. They often use periodic structures, micro-perforations, or composite layers to manipulate sound propagation. In many designs, fabrics act as the outer layer—both protecting the internal structure and influencing acoustic response.

They work by altering the way sound energy interacts with a surface. This could mean converting sound energy into heat through friction within the fibers, reflecting certain frequencies, or allowing air movement for targeted absorption. The fabric’s weave tightness, fiber type, and surface finish all contribute to this effect.

What role does fabric density play?

Fabric density determines airflow resistance—known in acoustic terms as flow resistivity. A higher-density weave can reflect more sound but may reduce breathability. In contrast, a lighter weave may improve mid-to-high frequency absorption. Many high-performance designs blend polyester microfibers (source) with natural cotton to achieve balanced results.

Why is porosity important in acoustic fabrics?

Porosity affects how air and sound pass through a fabric. Fabrics like open-weave wool blends (source) allow sound to enter the structure, where it can be dissipated by deeper layers. In metamaterials, the surface fabric must be chosen so it doesn’t block the performance of the underlying design.

Which Fabrics Have the Best Sound Absorption?

Sound absorption in fabrics comes from a mix of fiber type, thickness, and weave structure. The best fabrics for acoustic metamaterials are those that can work in harmony with other layers, like foams or honeycomb structures, to enhance the sound-dampening effect.

In most cases, thicker and more textured fabrics absorb better, especially in mid-to-high frequencies. Wool felts, heavy cotton canvases, and special acoustic polyesters are common in high-end projects.

Which natural fabrics are most effective for absorption?

Wool is a standout. Its natural crimp traps air, increasing sound absorption efficiency. For example, merino wool panels (source) combine sustainability with excellent acoustic properties. Cotton, especially in thick twill or flannel forms, also performs well in certain applications.

Are synthetic fabrics better for specific frequencies?

Yes. Microfiber polyester fabrics (source) can be engineered for consistent pore size, optimizing absorption at targeted frequency ranges. This makes them ideal for precision acoustic metamaterials, where designers can tailor the fabric for specific sound control goals.

Can Sustainable Fabrics Be Used for Acoustic Design?

Sustainability is no longer optional—it’s a demand from clients worldwide. Many believe high acoustic performance can only be achieved with synthetics, but our experience shows eco-friendly fabrics can be engineered for exceptional acoustic results.

Natural and recycled fibers offer both environmental and performance benefits. Recycled PET fabrics, organic cotton blends, and bamboo-derived textiles are now common in architectural and product-level acoustic applications.

How does recycled polyester compare in performance?

Recycled polyester, or rPET (source), matches virgin polyester in durability and acoustic efficiency. It’s often used in public spaces where both environmental certifications and fire safety standards must be met.

Can plant-based fabrics meet acoustic industry standards?

Yes. Bamboo viscose and hemp (source) have shown strong potential for mid-frequency absorption. With proper backing materials, they can perform on par with traditional synthetics, while offering a sustainable brand story.

How to Choose Fabrics for Noise Control Applications?

Choosing fabrics for noise control is about more than just sound ratings—it’s about matching the acoustic profile, aesthetic, durability, and compliance requirements of the project. Whether for concert halls, open-plan offices, or home studios, the right choice starts with understanding the sound environment.

The process should involve testing, prototyping, and certification. Our in-house CNAS-accredited lab allows us to test absorption coefficients, flammability, and durability before mass production.

What testing standards should fabrics meet?

For most export projects, fabrics must comply with ISO 354 sound absorption tests (source) and local fire safety regulations. In the US, that often means NFPA 701 compliance.

How can designers ensure aesthetic and functional balance?

We often recommend designers create small mock-up panels using shortlisted fabrics (source) to assess both visual and acoustic qualities before committing to full-scale production.

Conclusion

Acoustic metamaterials represent the meeting point of textile engineering and sound science. The choice of fabric is critical—not only for acoustic performance but also for durability, aesthetics, and sustainability. By understanding factors like density, porosity, and fiber type, buyers can make informed choices that improve both sound quality and the user experience.

If you are considering custom acoustic fabric development, we can provide one-stop support—from weaving and dyeing to testing and export. For collaboration inquiries, contact our Business Director Elaine at elaine@fumaoclothing.com to start developing your own high-performance fabrics with Shanghai Fumao.