As the demand for wearable technology and sustainable energy grows, photovoltaic-integrated solar charging textiles have emerged as a revolutionary solution for industries ranging from fashion to outdoor gear. Yet for many buyers, knowing exactly where to source these innovative fabrics can be a challenge. The market is fragmented, and misinformation is common.

You can find photovoltaic-integrated solar charging textiles from specialized textile manufacturers, research-driven fabric suppliers, and industry trade shows. China, particularly Keqiao in Zhejiang, has become a key hub for producing these advanced fabrics at scale while maintaining high quality and customization options.

If you want to integrate solar technology into your textile products, you must understand not just where to buy them, but also what makes a supplier reliable, how to evaluate technical quality, and how to handle logistics for global shipment. Let’s break it down step-by-step.

Top Global Sources for Solar Charging Fabrics

Finding the right source starts with knowing who leads the market. Global suppliers vary in terms of quality, innovation, and scalability, but certain hubs consistently stand out.

The top global sources for photovoltaic-integrated solar charging textiles include China’s Keqiao textile cluster, specialized European technical textile firms, and select US-based research spin-offs. China offers unmatched production capacity and cost efficiency, while Europe often leads in high-end R&D applications.

These sources have not only invested in solar cell integration technology but also have supply chain systems to deliver on time. The key is to identify those with proven track records.

Which regions lead in production capacity?

China’s Keqiao region is the undisputed leader in textile manufacturing scale. Many companies here, such as textile exporters with integrated weaving and coating facilities, have adopted photovoltaic modules into their production lines. Europe’s technical textile industry is smaller in volume but strong in research, especially in countries like Germany and Italy.

Are trade shows a good place to find suppliers?

Yes. Trade fairs such as Techtextil Frankfurt and China’s Keqiao Textile Expo bring together innovators in solar-integrated fabrics. They allow buyers to touch, test, and negotiate directly with producers, reducing sourcing risks.

Key Features to Look for in Photovoltaic Fabrics

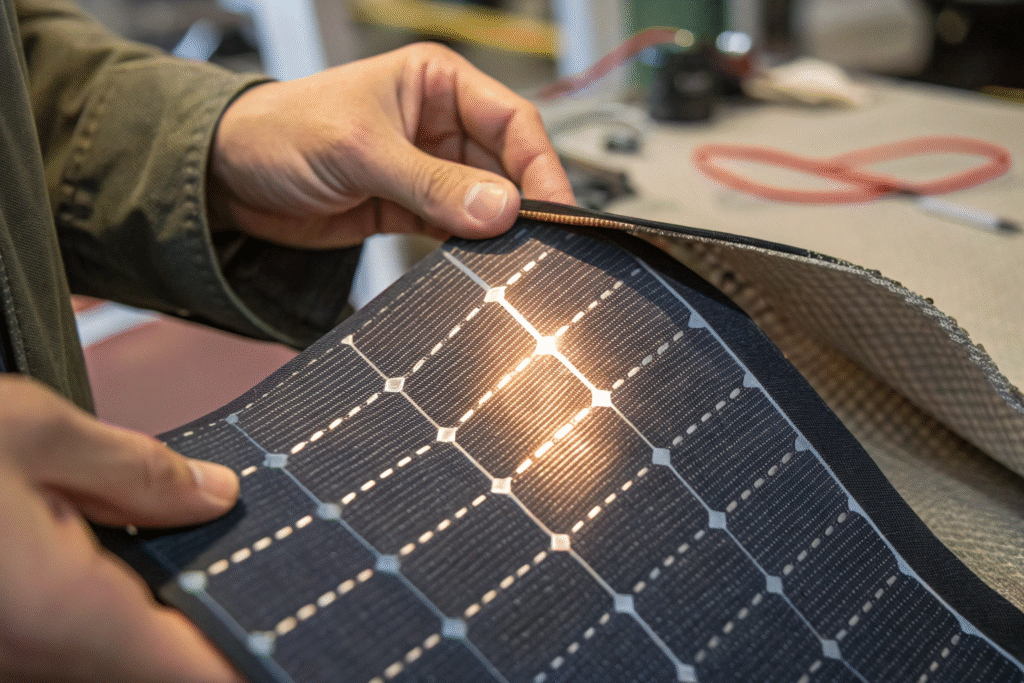

Not all solar charging textiles are created equal. Some may have higher conversion rates, better flexibility, or improved weather resistance.

When sourcing, focus on conversion efficiency, durability, flexibility, weight, and integration quality. These determine not just performance, but also user comfort and product lifespan.

What is the ideal solar conversion efficiency?

A good benchmark is 10–15% conversion efficiency for flexible photovoltaic fabrics. Many suppliers provide lab-tested results certified by SGS or Intertek. These certifications verify that the fabric’s photovoltaic layer performs as promised.

How important is flexibility and washability?

Very important. Fabrics must retain flexibility without cracking, and ideally be washable under gentle conditions. This is crucial for wearable applications where comfort and maintenance matter.

How to Verify Supplier Reliability

Even with attractive product claims, you must ensure your supplier is credible and capable.

Verifying reliability involves checking certifications, conducting factory audits, requesting production samples, and evaluating past client feedback.

Should I request third-party quality testing?

Absolutely. Engaging third-party labs like Bureau Veritas or TÜV SÜD ensures unbiased quality verification. They can check photovoltaic output, fabric strength, and coating durability.

How can I assess their production capacity?

Request a factory visit or virtual tour. Reliable suppliers will show weaving machines, coating lines, and solar integration units. Many Chinese factories in Keqiao provide live video factory tours to international buyers.

Best Practices for Global Shipping and Customs

Even if you secure the perfect fabric, poor logistics can delay your product launch.

Best practices include using experienced freight forwarders, understanding tariff codes, and preparing complete documentation for customs clearance.

What shipping terms are most common for these fabrics?

Terms like FOB (Free on Board) and CIF (Cost, Insurance, Freight) are standard. Many exporters work with freight forwarding companies who can handle complex solar fabric shipments efficiently.

How can I minimize tariff and clearance delays?

Work with suppliers who have export experience in your target country. For the US, understanding HTS codes for solar-integrated textiles can reduce errors. Some Chinese exporters offer bonded warehousing to speed up customs processing.

Conclusion

Photovoltaic-integrated solar charging textiles are no longer a futuristic concept—they are a market reality. Knowing where to find them, what features to prioritize, how to verify your supplier, and how to handle global logistics will give you a competitive edge in this emerging sector.

If you are ready to explore custom manufacturing for solar-integrated fabrics, we at Shanghai Fumao have the capacity, certifications, and global logistics expertise to deliver from sample to bulk shipment. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start your project today.