Medical graduated garments, such as compression stockings, arm sleeves, and recovery wear, require fabrics that combine precision engineering with medical-grade performance. The right choice of fabric not only determines comfort but also impacts the garment’s therapeutic effectiveness, durability, and safety. After decades in the textile industry, I have seen how subtle changes in fiber composition, weave density, and finishing can dramatically change the way these garments perform in real life.

Selecting the optimal compression fabric is a balance of elasticity, recovery, breathability, and skin compatibility. In my work with global brands, I have observed that the best results come from a careful match between the compression class (e.g., Class I, II, III) and the physical properties of the textile—paired with rigorous quality control and compliance with medical standards.

Medical garments are not just about squeezing the body—they’re about controlled, graduated pressure that supports circulation without causing discomfort or skin damage. This is where fabric technology plays the starring role, and why I’ll walk you through the considerations from both a technical and practical perspective.

How Do Compression Levels Affect Fabric Choice?

Graduated compression garments are prescribed in different levels—measured in millimeters of mercury (mmHg)—and each level demands specific fabric engineering. A Class I garment (15–20 mmHg) may need a softer knit with higher breathability, while Class III (30–40 mmHg) demands a denser structure with strong elastic recovery.

The science behind this is straightforward: the higher the required compression, the greater the tensile strength and modulus of the fabric must be. That means fiber selection, yarn count, and knitting technique all change depending on the target pressure range.

What Fabric Stretch Ratios Are Ideal for Class I Compression?

For light compression, we often use double-covered spandex blended with nylon or polyester, targeting a stretch ratio of 100–120% in circumference. This ensures a snug fit without creating restrictive hotspots. You can read more about spandex textile properties and how they interact with moisture management in light compression wear.

We also factor in warp knitting methods, which allow better control of stretch distribution. For Class I garments, this results in softer handfeel and improved long-term comfort for patients using them daily.

How Does Yarn Denier Influence Class III Compression?

In higher compression classes, we increase yarn denier (thickness) and select high-tenacity fibers to achieve the required pressure. This typically means a 200–300 denier nylon combined with spandex that can handle prolonged elongation without losing recovery. Research from ScienceDirect shows that higher denier yarns distribute force more evenly, reducing localized strain on the skin.

We also employ multi-layer knitting structures that trap less heat but deliver strong compression. This is vital for patients who need to wear Class III garments for extended medical treatment.

Best Synthetic Fibers for Medical-Grade Compression

Synthetic fibers dominate the medical compression sector because they offer predictable stretch, durability, and processing consistency. In our production, the top three synthetic choices are spandex, nylon, and polyester—each playing a different role in compression performance.

Why Is Spandex the Backbone of Compression Fabrics?

Spandex (also known as elastane) delivers the essential stretch and recovery in compression fabrics. It can elongate up to 500% and return to its original length without permanent deformation. This is why brands like Invista’s Lycra have set the benchmark in the industry.

In our factory, we prefer double-covered spandex to protect the elastic core from abrasion and chemical damage. Studies in MDPI Polymers Journal confirm that covered spandex not only extends garment lifespan but also improves patient comfort by preventing skin irritation.

How Does Nylon Add Strength and Smoothness?

Nylon is prized for its tensile strength, abrasion resistance, and smooth texture. This makes it ideal for outer layers of compression garments, where durability and skin glide are critical. The American Fiber Manufacturers Association highlights nylon’s balance between lightweight feel and structural integrity.

In our blends, nylon also boosts dye uptake, allowing us to offer medical garments in a wide range of colors without compromising medical function—important for patients who prefer less clinical-looking apparel.

Natural and Eco-Friendly Options for Graduated Garments

While synthetics dominate, some patients demand natural or sustainable options. For sensitive skin, natural fibers can reduce irritation risk, though they require careful engineering to meet compression standards.

Can Organic Cotton Work in Medical Compression?

Organic cotton is breathable and hypoallergenic, making it a patient-friendly choice. However, pure cotton lacks the necessary elasticity, so we blend it with spandex for controlled stretch. Cotton Incorporated has shown how cotton-spandex blends can achieve both comfort and compression when engineered with tight knits.

For eco-conscious clients, we also use GOTS-certified organic cotton, ensuring full traceability from farm to fabric.

How Does Tencel Contribute to Comfort and Sustainability?

Tencel (lyocell) is a regenerated cellulose fiber known for moisture management and silky softness. The Lenzing Group has documented its use in activewear and medical textiles, where its smooth surface reduces chafing.

We combine Tencel with spandex to produce garments that are not only sustainable but also highly functional, providing consistent graduated pressure without trapping excess heat.

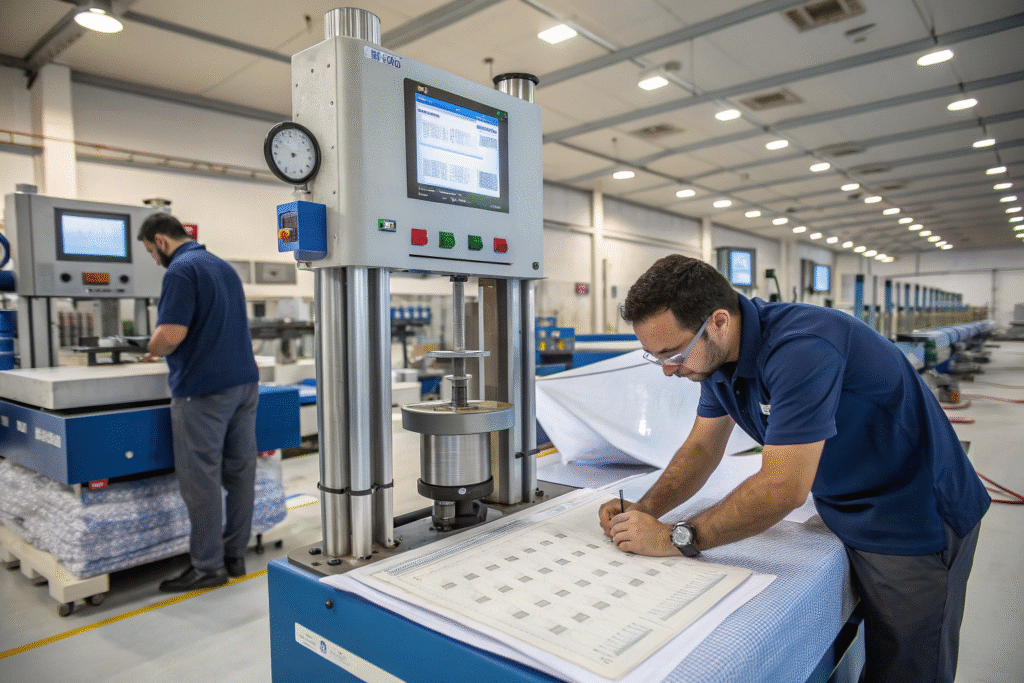

Key Quality Control Standards for Medical Compression Fabrics

Without stringent quality control, even the most advanced compression fabric can fail in medical application. This is why our factory follows international standards like ISO 13485 for medical devices and Oeko-Tex for textile safety.

What Testing Ensures Accurate Compression Levels?

We use pneumatic compression testers to measure the actual mmHg delivered by the fabric when stretched over a leg form. The ISO 14877 standard outlines acceptable tolerance ranges for medical hosiery.

Consistent testing prevents the common issue of “pressure drift” over time, which can reduce the garment’s therapeutic effect.

How Do We Guarantee Skin Safety and Durability?

Every batch undergoes cytotoxicity testing, colorfastness evaluation, and abrasion resistance measurement. According to SGS, these tests ensure that garments remain safe and functional throughout their lifespan.

We also monitor chemical residues to comply with REACH regulations, especially important for products sold in the EU.

Conclusion

Choosing the optimal compression fabric for medical graduated garments is a multi-factor process that balances stretch, strength, breathability, and skin safety. From lightweight Class I stockings to high-pressure Class III sleeves, every specification matters.

If you are looking to produce your own medical-grade compression fabrics or garments, we at Shanghai Fumao have the expertise, infrastructure, and global logistics to deliver exactly what your market needs. Contact our Business Director Elaine at elaine@fumaoclothing.com to start your project today.