In the textile industry, finding reliable temperature-regulating Outlast® fabrics can be a challenge. Many buyers waste time on suppliers that promise innovation but deliver subpar quality. This frustration is even greater when dealing with overseas sourcing, where risks in quality control, logistics, and compliance can easily derail projects.

The best solution is to identify trusted suppliers who understand both the technology behind Outlast® and the needs of global buyers. This means working with companies that have proven track records, advanced testing capabilities, and an integrated supply chain to ensure every meter meets international standards.

The good news is, with the right strategy, you can secure high-performance Outlast® fabrics that not only regulate body temperature but also align with your production timelines, compliance requirements, and budget expectations.

What Makes Outlast® Temperature-Regulating Fabrics Unique?

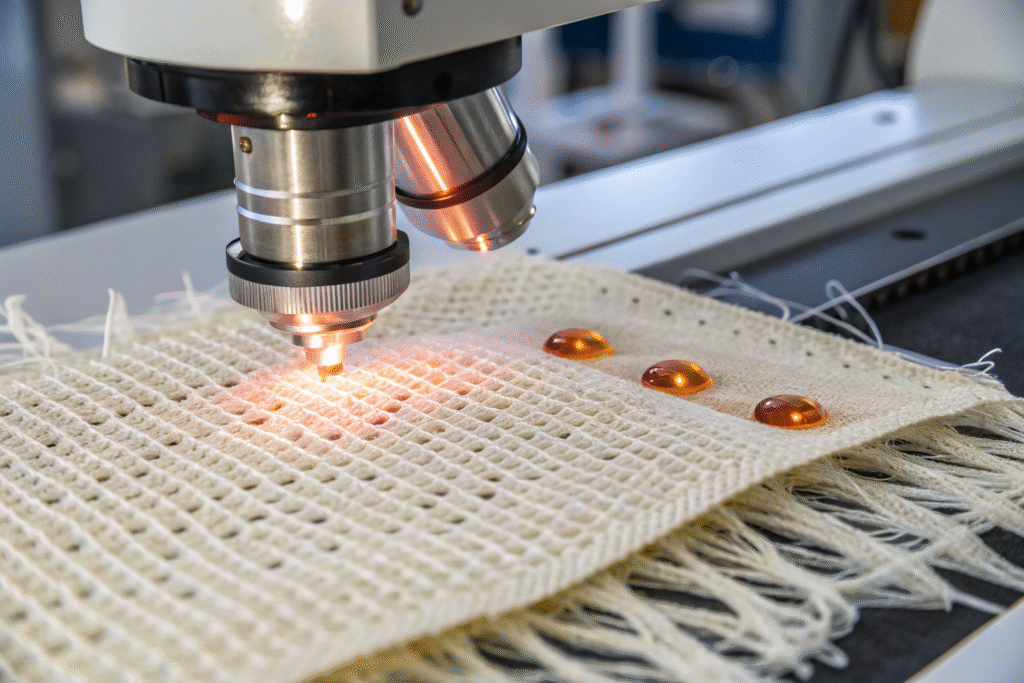

Outlast® fabrics are not ordinary textiles. They incorporate Phase Change Material (PCM) technology, originally developed for NASA, which absorbs, stores, and releases heat to maintain a stable microclimate next to the skin. This makes them ideal for clothing, bedding, and accessories used in variable temperature conditions.

Outlast® technology works by balancing heat and moisture. When your body temperature rises, the PCM absorbs excess heat. When it drops, the stored heat is released back. This reduces overheating and chilling, leading to greater comfort compared to conventional fabrics.

Why is Outlast® better than traditional thermal fabrics?

Outlast® fabrics actively regulate temperature, while traditional materials simply insulate or wick moisture. According to Outlast Technologies, the PCM microcapsules are permanently embedded into the fibers, so the performance does not wash out over time.

How does Outlast® improve product value in apparel?

When integrated into garments, Outlast® fabrics enable brands to market advanced comfort features. This creates opportunities for premium pricing and better differentiation in competitive segments like outdoor clothing and athleisure wear.

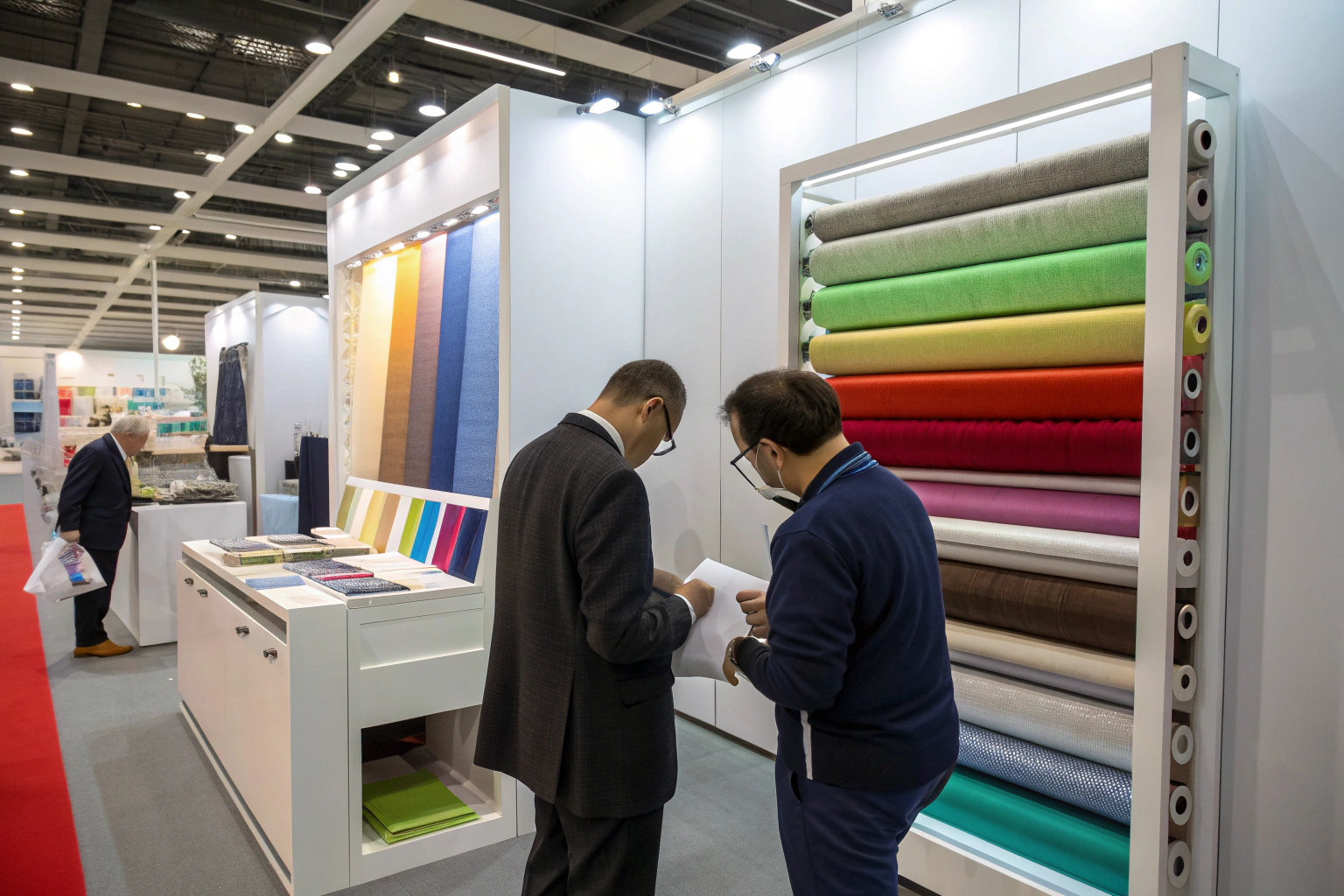

Top Global Sources for Outlast® Lined Textiles

Global demand for Outlast® temperature-regulating fabrics has led to a growing supplier base across multiple continents. The best sources are usually in countries with strong textile infrastructure and certification systems.

China remains the leading production hub thanks to its integrated supply chain, competitive costs, and rapid development capability. However, other countries like Germany (where Outlast Technologies is headquartered) and the USA also offer high-quality production.

Which countries produce the best Outlast® fabrics?

Germany and the USA offer precision engineering, while China offers scale and speed. For example, Keqiao, Zhejiang is home to over 80 manufacturers specializing in advanced functional textiles.

How to identify authentic Outlast® suppliers?

Look for licensing under Outlast Technologies’ trademark. Reliable suppliers should also provide testing reports from SGS or ITS to confirm thermal regulation performance and safety compliance.

How to Choose the Right Outlast® Fabric Supplier?

Choosing the right supplier for Outlast® fabrics is not just about price. It’s about quality assurance, development capacity, and supply stability. The wrong choice can result in shipment delays, inconsistent fabric performance, and brand reputation damage.

The best suppliers offer transparent quality control systems. This includes CNAS-accredited testing, real-time tracking of production batches, and responsive customer service that can adapt to design changes quickly.

What certifications should a supplier have?

Suppliers should have valid OEKO-TEX Standard 100 and GRS (Global Recycled Standard) certifications if they use recycled content. These guarantee safety and sustainability, which are increasingly demanded by Western markets.

How to evaluate supplier development speed?

Ask for sample lead times. In leading textile hubs, premium suppliers can provide Outlast® fabric samples within 48 hours and bulk delivery within weeks, similar to performance standards at Fumao Fabric.

Tips for Buying Outlast® Fabrics from China

Sourcing Outlast® fabrics from China offers great value, but it also requires strategic planning. Many buyers overlook due diligence in areas like quality verification, tariff optimization, and shipping schedule alignment.

To succeed, combine supplier vetting with proactive logistics and compliance checks. This will help you avoid common pitfalls like inconsistent dye lots, customs delays, or unexpected tariff costs.

How to manage tariffs and shipping costs?

Work with suppliers who understand U.S. tariff codes and can ship through bonded warehouses or duty-free zones. This can significantly reduce landed costs for large orders.

What is the best way to ensure quality before shipment?

Use third-party inspection companies like Intertek to check fabric quality before it leaves China. This protects against surprises and ensures your Outlast® fabrics meet your product specifications.

Conclusion

Finding temperature-regulating Outlast® lined fabrics requires understanding the technology, identifying reliable suppliers, and managing the sourcing process with precision. By focusing on suppliers with proven expertise, robust certifications, and strong logistics capabilities, you can secure fabrics that enhance your product performance and market competitiveness.

If you’re ready to develop your own line of Outlast®-based fabrics or garments, Shanghai Fumao is here to help. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can support your project from concept to delivery.