In today’s fast-paced fashion and textile markets, brands and manufacturers are constantly seeking performance fabrics that combine style, comfort, and functionality. Traditional waterproofing often fades after several washes, leaving consumers dissatisfied and leading to costly returns. This is where plasma-treated fabrics offer a game-changing solution — providing long-lasting hydrophobicity without compromising breathability or aesthetics.

Plasma-treated fabrics deliver permanent water repellency by altering the fiber surface at a molecular level, not by coating it with chemicals. This ensures the treatment withstands repeated washing, exposure to sunlight, and mechanical abrasion. For brands competing in high-demand sectors like sportswear, outdoor apparel, and luxury fashion, this technology translates into higher product value, greater customer satisfaction, and fewer warranty claims.

By understanding how plasma treatment works, why it outperforms conventional waterproofing, and where to source these fabrics, you can make a smarter investment in your supply chain — one that meets the expectations of a global market increasingly driven by quality and sustainability.

How Does Plasma Treatment Create Lasting Hydrophobicity?

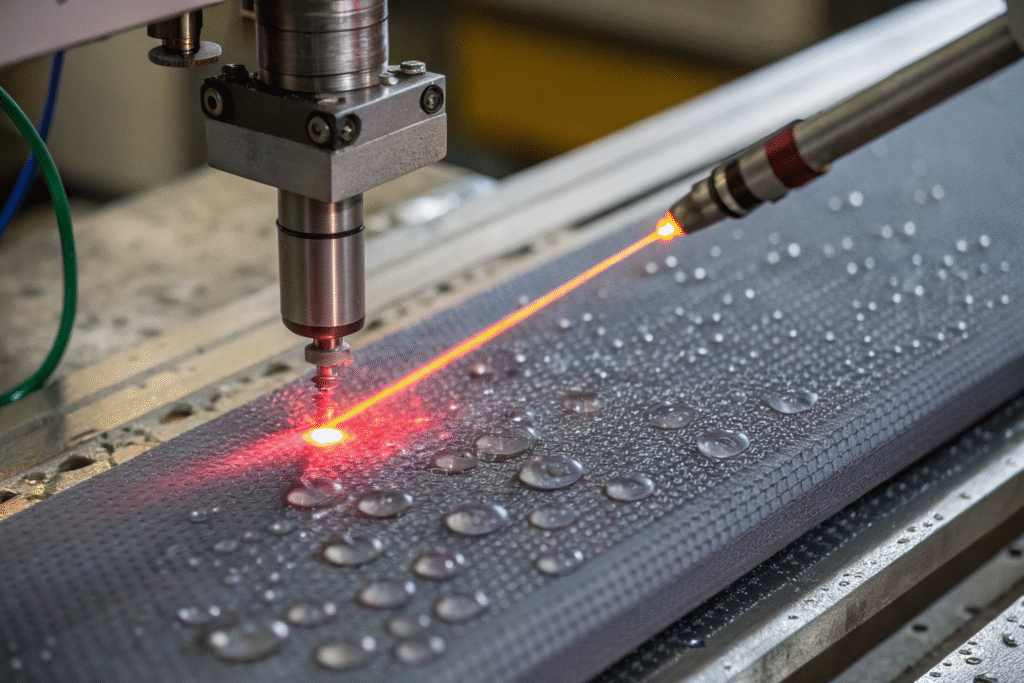

Plasma treatment modifies the fabric’s surface using ionized gas, creating a nano-scale structure that repels water. Unlike topical finishes that rely on a chemical layer, plasma technology permanently changes the fiber’s surface energy, making it hydrophobic for the life of the fabric. This method avoids the problem of coatings washing away or degrading over time.

By using plasma treatment, manufacturers achieve permanent hydrophobicity without adding extra weight or altering the fabric’s hand feel. This is especially critical for applications like activewear and outdoor gear where flexibility and breathability are as important as water resistance. In addition, the process is eco-friendly, using minimal resources and generating little to no harmful waste.

What Makes Plasma Technology Different from Spray-On Coatings?

Plasma treatment works at the atomic level, ensuring uniform coverage and deep surface modification. Traditional waterproof sprays or dip coatings only create a superficial layer. As a result, sprays are vulnerable to abrasion and laundering, leading to reduced performance after just a few uses. Plasma-treated fabrics, by contrast, retain hydrophobicity even after dozens of wash cycles.

The technology also offers better adhesion between the treatment and the fiber, meaning you avoid the “peeling” effect seen with some PU-coated fabrics. This long-lasting performance can reduce product returns and strengthen brand trust.

Why Is Plasma Treatment More Sustainable?

Because plasma treatment uses less water and no harmful chemicals like PFCs, it meets stringent environmental standards such as OEKO-TEX® Standard 100 and bluesign®. Traditional methods often require energy-intensive drying and curing, but plasma treatment is energy-efficient and scalable. For brands targeting eco-conscious markets, this aligns with growing demand for sustainable sourcing and transparent manufacturing practices.

What Are the Key Advantages for Apparel and Outdoor Brands?

For apparel and outdoor brands, plasma-treated fabrics offer a rare combination of functional performance, sustainability, and cost-efficiency. They are particularly suitable for markets where durability, breathability, and eco-compliance are major selling points.

These fabrics maintain their hydrophobicity under heavy use, meaning consumers experience consistent performance over the lifetime of the garment. This builds brand loyalty and supports premium pricing strategies. Additionally, because plasma treatment is compatible with a wide range of fibers, brands can use it across product categories — from lightweight summer jackets to heavy-duty tents.

How Do Plasma-Treated Fabrics Improve Product Longevity?

Long-lasting performance is a major differentiator. With plasma-treated materials, brands can promise water resistance even after repeated laundering and exposure to outdoor elements. This reliability can be marketed alongside certifications like ISO 4920 spray rating tests to prove performance claims. For outdoor gear, this reduces warranty issues and strengthens customer trust.

Can Plasma-Treated Fabrics Enhance Brand Image?

Yes, especially for brands positioning themselves as innovators or eco-leaders. Partnering with suppliers that hold GOTS or GRS certifications helps communicate your commitment to responsible manufacturing. The technical sophistication of plasma treatment can also be used in marketing campaigns to differentiate from competitors who still rely on outdated chemical methods.

How Do Plasma-Treated Fabrics Compare to Chemical Coatings?

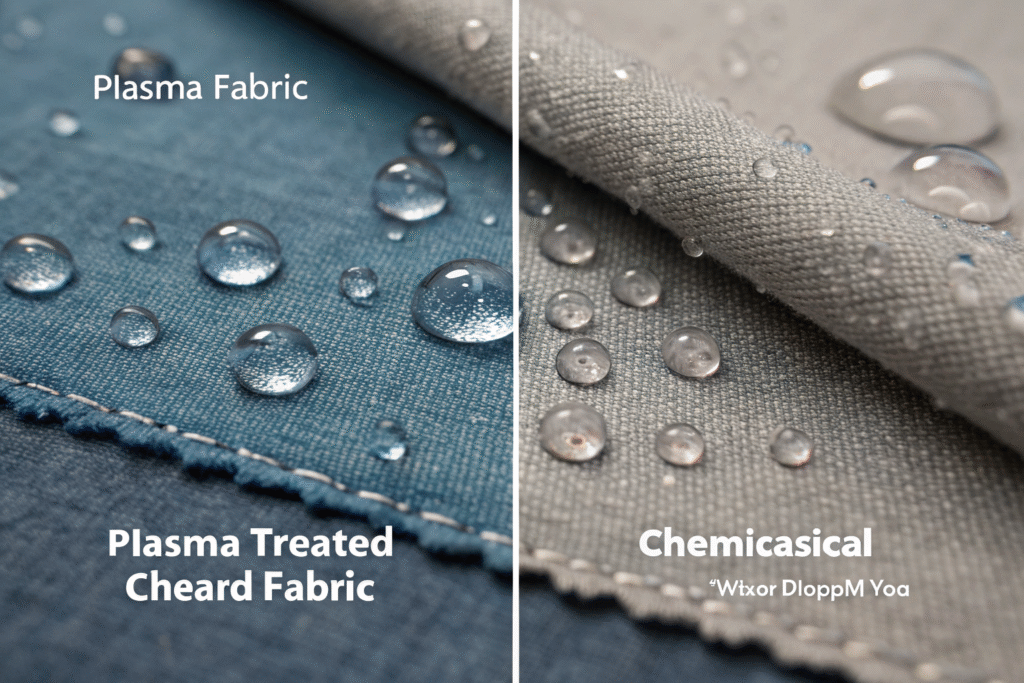

When evaluating hydrophobic solutions, it’s important to understand the fundamental differences between plasma treatment and chemical coatings. While both can repel water, their durability, sustainability, and tactile qualities differ significantly.

Plasma-treated fabrics deliver hydrophobicity without sacrificing breathability or adding stiffness, while chemical coatings often create a plastic-like feel and degrade quickly. Moreover, plasma processes are non-toxic and require less maintenance, making them better suited for high-performance and eco-sensitive applications.

Which Method Offers Better Wash Durability?

Chemical coatings can lose effectiveness after 5–10 wash cycles, especially when exposed to heat or detergents. Plasma-treated fabrics maintain their performance through 30+ washes, as verified by AATCC 22 water repellency tests. This durability is especially valuable for uniforms, sportswear, and reusable outdoor gear.

Are There Cost Differences Over the Product Lifecycle?

While plasma treatment may have a slightly higher upfront processing cost, it often proves more economical over time. The reduced need for re-treatment, fewer product returns, and the ability to market products as "long-lasting" can offset the initial investment. Suppliers who combine plasma technology with efficient logistics solutions can help brands scale without eroding margins.

Where to Source Reliable Plasma-Treated Hydrophobic Fabrics?

Finding a dependable supplier is crucial for integrating plasma-treated fabrics into your product line. Look for manufacturers with proven expertise, in-house quality control, and certifications that meet your market’s compliance needs.

At Fumao Fabric, we offer plasma-treated fabrics tailored to the needs of global fashion and outdoor brands. With over 20 years in the textile industry and a full vertical supply chain, we ensure consistent quality from weaving to finishing. Our CNAS-certified lab verifies hydrophobic performance using international testing standards.

What Should You Check Before Choosing a Supplier?

Evaluate the supplier’s testing capabilities, sample turnaround time, and export experience. Working with a partner who understands customs regulations and offers flexible shipping options can minimize delays. Also, request references from clients in your target market to verify service quality.

Can Fumao Fabric Meet High-Volume and Custom Orders?

Yes. Our integrated manufacturing allows us to handle both small-batch and large-scale production, with the ability to customize fabric weight, weave, and finish. Our experience with Alibaba global buyers and direct partnerships with major brands ensures smooth communication, fast sampling, and reliable delivery.

Conclusion

Plasma-treated fabrics represent the future of durable, eco-friendly hydrophobic textiles. By modifying fibers at a molecular level, they deliver permanent water repellency without compromising breathability or comfort. This technology aligns perfectly with the growing demand for sustainable, high-performance apparel and gear.

If you are ready to explore how plasma-treated fabrics can elevate your product line, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let’s work together to create fabrics that inspire confidence, protect the environment, and stand the test of time.