Protective workwear is more than just a uniform—it is the last line of defense between workers and workplace hazards. For buyers, importers, and manufacturers, ISO 13688 compliance is not optional; it is a global standard that ensures safety, comfort, and durability in garments designed for industrial use. Yet with so many textile options available, choosing the right one can feel overwhelming.

In short, the best ISO 13688 compliant fabrics are those that balance protection, comfort, and cost-efficiency—ensuring they meet rigorous safety standards while also delivering long-term wearability in challenging environments.

That is why, in this guide, I will break down the core requirements of ISO 13688, explore the top-performing fabrics, and share how to choose suppliers that can guarantee compliance while meeting production deadlines.

Key Requirements for ISO 13688 Certified Fabrics

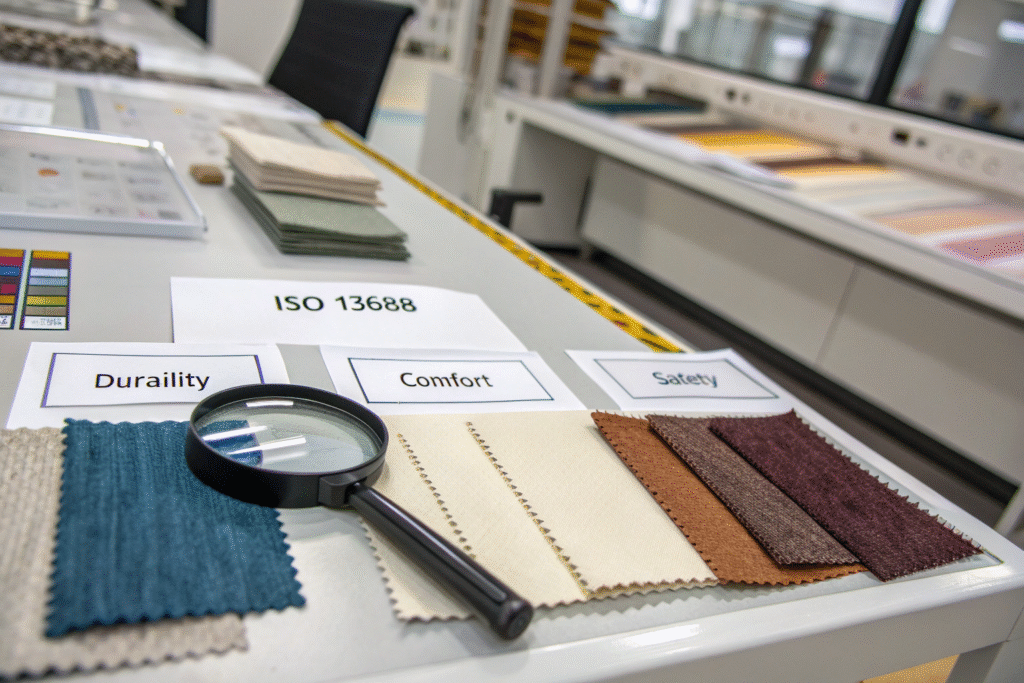

Understanding ISO 13688 is the foundation of making the right textile choice. The standard defines general performance requirements for protective clothing, including ergonomics, innocuousness, size designation, aging, compatibility, and marking. It is often used in combination with other specific protective clothing standards.

The most important part for fabric buyers is that ISO 13688 compliance means the textile is tested for skin safety, durability under stress, and comfort during prolonged wear. This directly influences how the garment will perform in real-life conditions, such as in construction sites, factories, or outdoor environments.

What makes a fabric compliant with ISO 13688?

ISO 13688 compliance requires meeting strict guidelines for mechanical strength, pH neutrality, colorfastness, and dimensional stability. For example, the ISO official guidelines clearly state that fabrics must not release harmful substances that could irritate skin. Additionally, compliance testing ensures that shrinkage stays within a set tolerance after multiple washes. Many buyers rely on certifications from SGS or ITS to validate these claims.

How is compliance tested and certified?

Testing involves multiple phases: lab analysis for harmful chemicals, mechanical tests for tensile and tear strength, and comfort evaluation for breathability and thermal properties. Fabrics like poly-cotton blends often pass due to their balance of durability and comfort. The certification process usually requires collaboration with accredited labs such as Intertek to ensure global recognition.

Top Fabric Types for Protective Workwear

Not all fabrics are created equal. In protective workwear, the choice of textile can make the difference between compliance and costly failure. While ISO 13688 covers general requirements, you also need to consider the specific hazards in the work environment.

Which fabrics offer the best protection in industrial settings?

For high-heat environments, aramid fibers like Kevlar are the gold standard. They resist flames and maintain structural integrity under extreme temperatures. In lower-risk settings, poly-cotton blends dominate due to their comfort and cost-efficiency, as detailed by DuPont’s Kevlar overview and Textile World. Coated fabrics with PU or PVC layers are preferred in environments with liquid hazards.

Are eco-friendly fabrics suitable for ISO 13688 compliance?

Yes—fabrics like recycled polyester and organic cotton can meet ISO 13688 standards if they pass the same performance and safety tests. Innovations in sustainable textiles are making it possible to combine eco-certifications with industrial safety, as seen in OEKO-TEX Standard 100 and Global Recycled Standard.

Balancing Comfort, Safety, and Durability

A compliant fabric is only effective if workers can wear it comfortably over long shifts. That is why ergonomics and fabric hand feel matter as much as tensile strength. ISO 13688 emphasizes not just protection but also ease of movement, weight balance, and comfort in various temperatures.

How can buyers ensure comfort without sacrificing safety?

The key is to select fabrics with blended fiber technology, such as cotton for softness and polyester for durability. Breathable coatings and moisture-wicking finishes further enhance comfort. Industry leaders like Gore-Tex Professional and Cordura have developed fabrics that meet both ISO standards and user comfort needs.

What durability factors matter most in heavy-duty workwear?

Durability is measured by abrasion resistance, seam strength, and resistance to pilling. Buyers should look for fabrics tested to EN ISO 12947 (Martindale test) to ensure longevity. References from BTTG Testing and Klopman International show how technical fabrics maintain shape and strength after months of use.

Choosing the Right Supplier for Compliance

Even the best fabric is useless if it is not sourced from a reliable supplier. Choosing the right partner ensures that quality control, documentation, and delivery timelines align with your business goals.

What should buyers ask suppliers before placing an order?

Questions should cover testing certifications, batch traceability, and after-sales support. You should request ISO 13688 test reports and confirm that the supplier works with recognized testing labs like Bureau Veritas and TÜV SÜD.

How do logistics and payment terms affect compliance projects?

Efficient shipping schedules, clear Incoterms, and secure payment options are critical. Late deliveries can jeopardize compliance contracts. Trusted suppliers often provide flexible payment terms and reliable logistics partnerships, as highlighted by Maersk and DHL Global Forwarding.

Conclusion

ISO 13688 compliance is not just a box to tick—it is an investment in safety, brand reputation, and operational efficiency. The right fabric offers the durability and comfort workers need, while also ensuring your products meet international standards.

If you are ready to develop your own ISO 13688 compliant protective workwear textiles, partner with us at Shanghai Fumao. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start your custom production today.