Smart textiles have evolved beyond moisture sensors and temperature control. Now, electroluminescent (EL) thread woven fabrics are redefining the relationship between textiles and light. Whether for wearable tech, stage costumes, safety vests, or dynamic fashion, these glowing fabrics offer mesmerizing aesthetics and real-world utility.

You can find electroluminescent woven textiles through specialty smart textile labs and suppliers in Asia and Europe. The best partners offer fiber integration, driver circuit customization, and support for low-MOQ prototype runs.

This article breaks down the sourcing process, technical requirements, and industry-leading vendors that offer EL-thread fabric integration—whether you need it for wearable LEDs or luminous signage jackets.

What Are Electroluminescent Thread Woven Textiles?

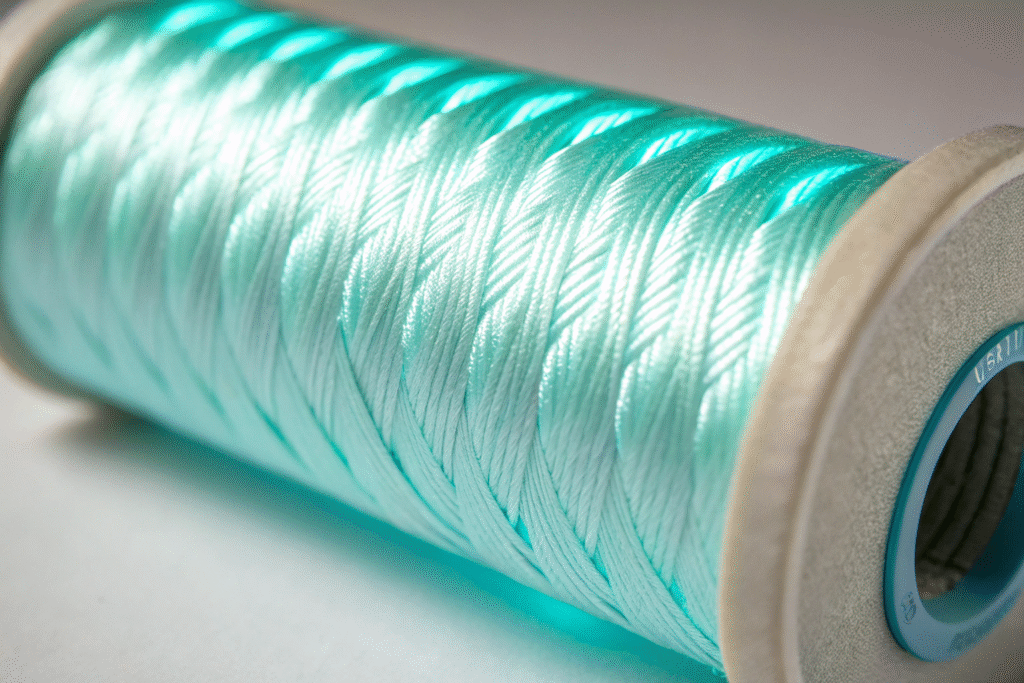

Electroluminescent thread is made of conductive materials like copper wire coated with phosphor, which glows when activated by a low-voltage alternating current.

When this thread is woven directly into fabric, it allows textiles to light up in patterns, pulses, or consistent glows, depending on how the circuits are designed.

How Is EL Thread Different from LED Panels?

Unlike traditional LED textiles, which may feel rigid or bulky, EL thread is ultra-thin, soft, and flexible. It can be sewn or woven directly into clothing without compromising comfort. Its uniform glow is ideal for fashion and visibility, while consuming far less power.

What Fabrics Are Compatible?

Most EL thread fabrics are built on polyester, nylon, or cotton blends—materials that can handle the tension of weaving and heat sealing during driver circuit integration. According to Lumigram, warp-knitted and plain woven bases offer optimal structure for fiber alignment.

Which Applications Benefit from EL Smart Fabrics?

From artistic expression to life-saving visibility, EL woven smart textiles serve multiple industries.

You’ll find them in stagewear, cycling gear, backpacks, pet accessories, and experimental fashion tech. They’re also growing in automotive interiors and military signaling garments.

How Are They Used in Wearable Fashion?

Designers use EL thread for interactive evening dresses, festival costumes, and digital couture. According to MakeFashion, EL-integrated textiles help merge circuits with aesthetics—especially when synced to music or movement.

Are There Safety and Utility Uses?

Yes. EL thread is being embedded into jackets, gloves, and shoes for night workers, cyclists, and emergency responders. Companies like GlowSafe Wearables are commercializing illuminated gear powered by portable drivers under 5V.

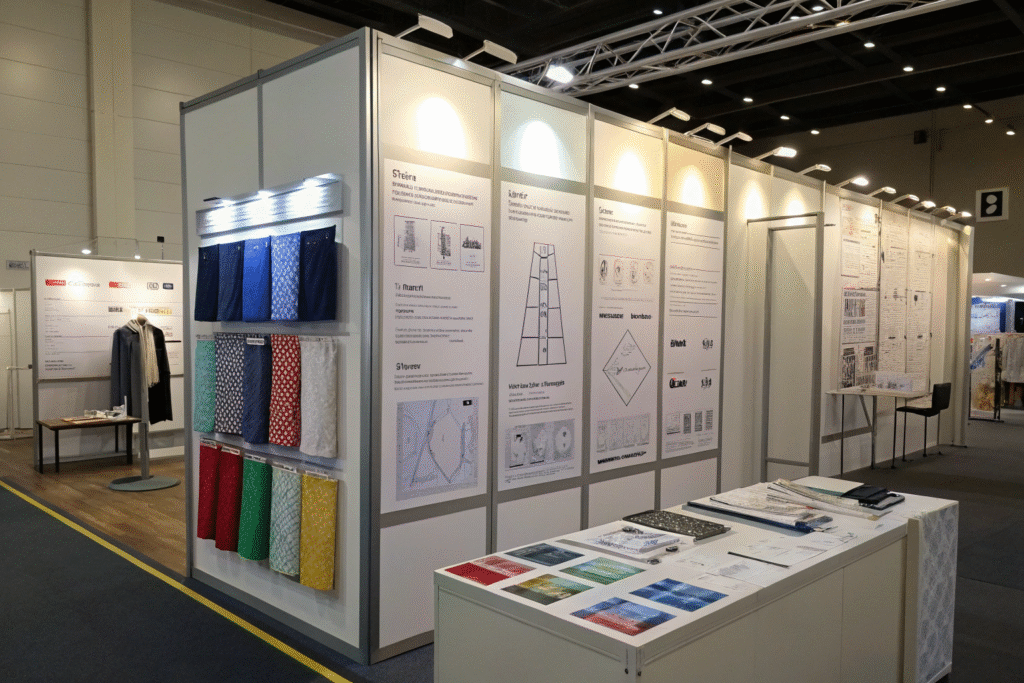

Who Are the Top Suppliers of EL Woven Smart Textiles?

Sourcing these advanced fabrics requires working with suppliers who combine textile engineering with electronics knowledge.

You can find EL textile suppliers in China (Shenzhen, Suzhou), Taiwan, and Germany. Many specialize in customized circuits, pattern programming, and waterproof housing for washable electronics.

Are There Reliable Vendors in China?

Yes. Shenzhen-based LumiGram Asia and Suzhou’s smart textile cluster offer low-MOQ prototypes, programmable controllers, and integration into apparel. We at Fumao Fabric also work with embedded fiber developers to deliver fabric-ready EL thread bases with custom yarn tensioning.

What About EU or US Suppliers?

European firms like Forster Rohner Textile Innovations and German-based Smart Textiles Platform Germany lead in aerospace and automotive applications. U.S.-based Adafruit Industries offers developer kits for prototyping but doesn’t focus on bulk weaving.

What Are the MOQ and Customization Options?

Because of their hybrid nature (textile + electronics), MOQ varies depending on your required features.

Standard EL thread woven fabrics start at 50–100 meters MOQ. Fully integrated garments or panel-ready fabrics with embedded circuits often require 300–500 meter commitments or NRE (non-recurring engineering) fees.

Can I Order Small Batches for Prototyping?

Yes. Many suppliers offer sample modules, 1-yard illuminated swatches, or cut-and-sew ready panels. On Tindie, you can purchase DIY EL textile kits for testing—though not for mass production.

What Can Be Customized?

At Fumao Fabric, you can customize:

- Fiber colors (blue, green, white, pink, etc.)

- Glow animation (steady, pulse, wave)

- Connector type (USB, coin battery, PCB)

- Surface base (woven mesh, oxford, interlock)

We also offer heat-sealing and lamination for outdoor or washable functionality, in collaboration with trusted EL partners.

Conclusion

Electroluminescent thread woven textiles are the future of interactive fabric innovation. They offer light, motion, safety, and art—all in one glowing thread. But sourcing them requires access to integrated suppliers who understand both circuits and cloth.

At Fumao Fabric, we bridge that gap. With textile roots in Keqiao and EL thread partnerships across Shenzhen, we co-develop next-generation fabrics for fashion-tech, smart uniforms, and glowing sportswear.

For prototyping, small-batch orders, or full-scale integration of EL threads into your smart apparel line, contact our Business Director Elaine at: elaine@fumaoclothing.com