Photochromic color-changing fabrics are transforming the activewear game. Imagine workout clothes that shift hues under sunlight, making each movement dynamic and expressive. For brands aiming to stand out, these fabrics offer unmatched interactivity and novelty—but they also bring sourcing challenges.

You can source photochromic sportswear fabrics from specialty textile mills that combine UV-reactive chemistry with moisture-wicking base materials. Leading suppliers in China, South Korea, and Japan offer small-batch development, lab testing, and export-ready support.

Whether you're a design startup or a performance wear distributor, this guide will help you understand how to find the right suppliers, certifications, and MOQ options for your project.

What Makes Photochromic Fabric Suitable for Sportswear?

Photochromic fabrics react to ultraviolet (UV) light, changing color when exposed to sunlight. But not all of them are fit for athletic use.

For sportswear, photochromic fabrics must combine UV-reactive coatings or embedded pigments with breathable, elastic, moisture-wicking base materials such as polyester-spandex or nylon blends.

How Does Photochromic Technology Work?

The fabric contains light-sensitive molecules—often spiropyrans or oxazines—that shift their molecular structure under UV exposure, producing a visible color change. Color Change Textiles explains this transformation in detail. Once UV light is removed, the molecules revert to their original state.

What Base Fabrics Are Commonly Used?

Performance polyester blends are most common. For example, lightweight polyester/spandex jerseys or mesh knits are ideal due to their compatibility with surface coatings. According to Spoonflower's tech fabrics overview, base fabrics must also support stretch and repeated washing.

Where Are the Best Suppliers of Photochromic Fabrics?

Only a limited number of mills specialize in color-changing tech textiles—and most are based in East Asia.

The leading exporters of photochromic fabrics include innovation clusters in Keqiao (China), Daegu (Korea), and Osaka (Japan). Some suppliers offer lab dips, small-batch yardage, and tech pack collaboration.

Who Are Trusted Suppliers in China?

In Keqiao, Zhejiang, companies like ours at Fumao Fabric work with specialty dyeing units to produce UV-reactive sports knits. On Alibaba, you can find verified factories offering bulk or sample orders with 2–3 week lead times.

Can I Source from Korea or Japan?

Yes, but expect higher costs and longer MOQs. Brands like Kolon Industries in Korea and Teijin in Japan offer proprietary photochromic and thermochromic lines—but often with corporate-level MOQs and limited third-party customization.

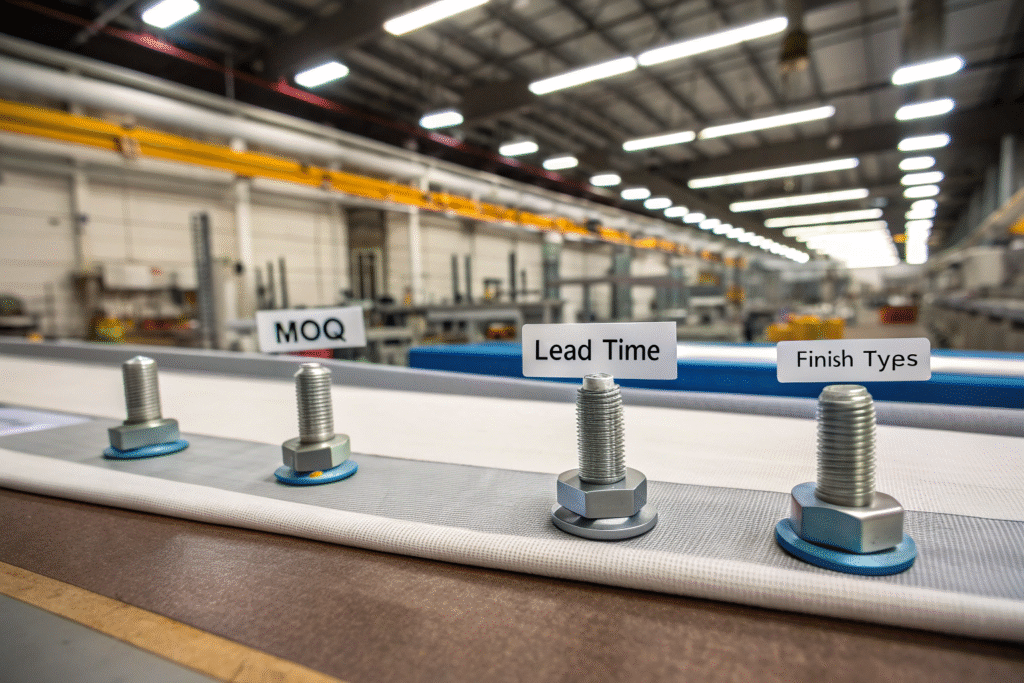

What Are the Minimum Order Quantities and Lead Times?

Photochromic fabrics are specialty items—so MOQ and development times vary depending on base fabric, coating chemistry, and whether patterns or solids are used.

Most suppliers require 100–300 meters MOQ for custom shades, though stock colors may start as low as 50 meters. Lead times range from 10 to 28 days depending on treatment complexity.

Can I Get Swatches or Sample Yardage?

Yes. Most mills (including ours) offer 1–3 yard strike-offs or swatches with both shaded and exposed color views. On Made-in-China, suppliers often list sample packs for ~$30–$60 per set.

What Affects Lead Time the Most?

Color complexity and base material availability. Custom hues require precise UV calibration in lab-controlled settings. Mills like Shinkong Textile explain that lightfastness and fade testing extend production timelines for outdoor sportswear fabrics.

What Certifications Should You Request?

Certification ensures the material is both safe and performance-verified. For sportswear brands entering the global market, especially the U.S. and EU, this is non-negotiable.

Look for OEKO-TEX Standard 100, REACH compliance, and SGS reports validating UV reaction, durability, and skin contact safety.

Why Is OEKO-TEX Critical?

OEKO-TEX 100 confirms that the dyes and finishes are free from harmful substances. This is particularly important for photochromic inks, which may include sensitive organic molecules. See OEKO-TEX explanation for full testing protocols.

How Do I Ensure UV Durability?

Ask for fade resistance test results—typically 20–40 cycle exposure under ISO 105-B02. SGS and Intertek offer these reports. A good supplier should show no more than 10% visual fading after repeated UV exposure.

Conclusion

Sourcing photochromic color-changing sportswear fabric takes more than finding the cheapest supplier—it requires balancing innovation, safety, performance, and logistics. Whether you’re prototyping glow-up yoga wear or sun-reactive running shirts, choosing the right textile partner ensures you deliver products that turn heads and meet compliance.

At Fumao Fabric, we support custom UV-reactive fabric development with fast lab dips, low MOQs, and export-ready certification. Our collaborative team in Keqiao integrates R&D with agile logistics to bring your color-changing sportswear designs to life.

To start your sourcing journey or get a quote, reach out to our Business Director Elaine at: elaine@fumaoclothing.com.