In the global fabric trade, knowing the weight of a textile isn't just technical—it's essential. Fabric weight directly influences drape, opacity, durability, pricing, and end-use applications. But how can you ensure consistent, comparable results across suppliers and factories?

That’s where ISO 3801 comes in. This international standard provides a clear and repeatable method to determine fabric mass per unit area (GSM), making it a cornerstone of textile quality control.

In this article, we’ll break down why ISO 3801 matters, how it's performed, where to apply it in sourcing and production, and how you can ensure your bulk orders align with buyers’ expectations.

What Is ISO 3801 and What Does It Measure?

ISO 3801 is an internationally recognized standard that defines how to determine the mass per unit area of fabric. This is typically expressed in grams per square meter (gsm or g/m²).

It standardizes the fabric weight measurement process across suppliers, labs, and production runs—removing guesswork and ensuring global consistency.

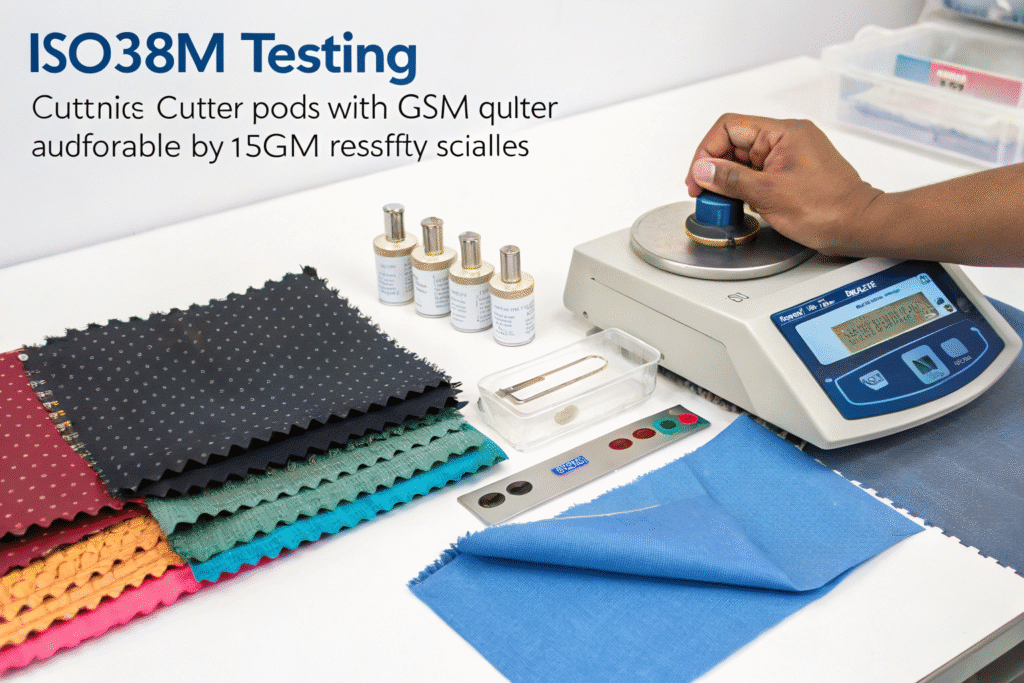

How Is the ISO 3801 Test Performed?

- Sample Size: A precise circular or rectangular piece is cut from the fabric. Common sizes include 100 cm² or 10x10 cm squares.

- Conditioning: Samples are brought to a standard humidity and temperature (usually 20±2°C and 65±4% RH).

- Weighing: The conditioned fabric is weighed using a digital lab scale accurate to at least 0.01g.

- Calculation: Mass is converted to grams per square meter using a standard formula.

Full methodology is detailed in ISO's official documentation.

Why GSM Matters in Every Category

- Apparel: Influences drape, opacity, and warmth

- Upholstery: Affects durability, abrasion resistance

- Curtains: Impacts hang and light-blocking

- Technical textiles: Defines compliance with safety or military specs

Even a ±10gsm difference can alter product usability and cost significantly.

Why Is ISO 3801 Critical for Global Fabric Buyers?

When importing fabric across borders, inconsistent fabric weights can cause compliance issues, production delays, or misleading pricing. ISO 3801 provides a common language between you and your suppliers.

If you’re quoting or comparing fabrics internationally, GSM must be measured using ISO 3801—or risk mismatched expectations and claims.

How Can ISO 3801 Prevent Costly Sourcing Errors?

Imagine sourcing “180gsm cotton jersey” from two vendors—one uses ISO 3801, the other doesn’t. You approve lab dips and bulk orders. When the shipment arrives, the fabric turns out to be 165gsm. That’s a deal breaker if you're producing:

- Sportswear with performance specs

- Uniforms requiring durability

- Garments for retail with published GSM data

In fact, brands like Adidas and Uniqlo include GSM in their BOMs and tech packs. Fabric must match those specs to avoid returns and losses.

Is ISO 3801 Legally Required?

Not by law, but it’s considered an industry best practice and is often referenced in buyer compliance manuals, customs declarations, and certification audits (like OEKO-TEX or GRS).

Many of our EU clients now require ISO 3801-certified lab data for each batch—even for natural fiber fabrics like ramie, cotton, or linen.

How to Ensure Your Supplier Follows ISO 3801 Standards?

Not all suppliers follow ISO testing without request. Many use local or internal methods that don’t account for humidity, surface density, or even cutting precision.

At Fumao Fabric, we follow ISO 3801 in all GSM testing for woven, knit, and coated fabrics—and we include QR-linked digital records for every production batch.

How Can You Verify Their Results?

Ask for:

- ISO 3801 test reports with batch ID

- Raw weighing images with timestamp

- Multiple sample results (average, min, max)

- Pre- and post-shrink GSM data (after ISO 6330 wash)

Platforms like Intertek or SGS also offer third-party verification if needed before shipment.

What GSM Tolerance Is Acceptable?

Typically, ±3% to ±5% is acceptable depending on:

| Fabric Type | Standard GSM | Tolerance |

|---|---|---|

| Cotton Jersey | 180gsm | ±5% |

| Woven Twill | 240gsm | ±3% |

| Polyester Fleece | 300gsm | ±4% |

| Linen Woven | 200gsm | ±5% (due to shrinkage) |

| Aramid Technical FR | 220gsm | ±2% (strict) |

At Fumao, we offer pre-shipment GSM verification and reject any rolls outside tolerance bands.

Which Buyers and Fabrics Most Rely on ISO 3801?

From small boutique brands to government contracts, GSM weight affects both product performance and pricing. ISO 3801 ensures everyone’s measuring on the same baseline.

Buyers sourcing for fashion, workwear, uniforms, home textiles, or industrial use all benefit from GSM validation based on ISO 3801.

Most Common Applications

- Fashion Brands: Track summer vs. winter fabric weights

- Hospitality Bedding: Weight defines luxury levels (e.g. 300TC at 130gsm)

- Military/Fire Gear: Weight consistency affects performance and layering

- Upholstery & Drapery: GSM impacts flame resistance and drapeability

Check out Textile Exchange standards that integrate ISO 3801 in weight-based fiber content declarations.

Do Coated Fabrics Use ISO 3801 Too?

Yes—but with care. For PU-coated, PVC-laminated, or bonded textiles, ISO 3801 can still apply as long as the method includes both sides and any backing layers.

Fumao offers dual-layer reporting (fabric-only + finished composite) for such cases.

Conclusion

In an increasingly standardized and globalized textile supply chain, ISO 3801 is not optional—it’s essential. Whether you're sourcing sportswear, uniforms, or upholstery fabrics, verifying GSM using ISO 3801 can protect your margins, ensure compliance, and boost buyer trust.

At Fumao Fabric, every order is tested under ISO 3801. Our QC team shares results in digital format, with QR codes and batch traceability, so your specs are protected from sampling to final delivery.

Want to ensure your next fabric shipment matches exact weight specs? Contact our Business Director Elaine at elaine@fumaoclothing.com and we’ll help you verify GSM standards from the roll to the report.