In the high-stakes world of motorsports, milliseconds matter—and so does every gram of fabric. Racing suit manufacturers face a dual challenge: deliver ultimate protection against flame and abrasion, while keeping garments as light and breathable as possible. That’s where lightweight para-aramid fabrics come in.

If you’re searching for high-performance materials that meet FIA, SFI, or ISO 11612 standards without sacrificing flexibility, sourcing the right para-aramid textile is critical.

This article covers where to find reliable suppliers, how to evaluate lightweight para-aramid fabric options, and what testing benchmarks you must consider before placing bulk orders for racing applications.

What Are Para-Aramid Fabrics and Why Are They Ideal for Racing?

Para-aramid fabrics—best known by trade names like Kevlar® and Twaron®—are synthetic fibers derived from aromatic polyamides. These materials are engineered to deliver exceptional heat resistance, tensile strength, and low weight—making them ideal for fireproof gear in motorsports.

Unlike traditional flame-resistant fabrics, para-aramid textiles maintain structural integrity at 400–500°C, and they don’t melt or drip under flame exposure.

What Makes Para-Aramid Fabrics Unique?

Para-aramids are not just fire resistant—they’re lightweight and breathable, especially when woven into ripstop, twill, or knit constructions. Their molecular structure resists both tearing and heat degradation, offering longer lifecycle than many FR-treated natural fibers.

Leading brands like DuPont’s Nomex® and Kevlar® have paved the way, but there are also alternatives from Teijin (Twaron), Kolon, and even Chinese para-aramid producers who now supply to the FIA and U.S. racing suit OEMs.

Why Is Weight So Important for Racing Gear?

A typical FIA-approved racing suit weighs between 1.2kg to 1.6kg. Every 100g saved on fabric weight can mean better driver comfort, quicker reaction, and reduced sweat retention. Lightweight para-aramid blends—often under 160gsm—help balance these performance factors with safety requirements.

Explore SFI’s 3.2A/5 spec for minimum requirements on multilayer suits using aramid composites.

Where Are the Best Global Sources for Lightweight Para-Aramid?

Para-aramid is a highly engineered textile, and sourcing it requires technical insight, compliance data, and trustworthy manufacturing partners.

The most cost-effective and customizable sources for lightweight para-aramid fabrics are in China and South Korea, while premium OEM-grade options come from Europe and the USA.

Can You Source Para-Aramid Fabrics from China?

Absolutely. At Fumao Fabric, we’ve worked with certified para-aramid spinners and weaving partners based in Zhejiang and Jiangsu, who produce 145gsm–180gsm para-aramid twills, ripstops, and interlocks. These fabrics meet EN ISO 11612 and can be laminated or quilted into racing suit layers.

Our QC team also assists in testing for LOI (Limiting Oxygen Index) and thermal shrinkage, ensuring performance at >450°C exposure.

For reference, check out Huatong’s aramid capabilities and Yantai Tayho’s portfolio—two of China’s recognized aramid fiber producers.

What About OEM-Approved Suppliers in Europe or USA?

If you’re supplying to high-end racing brands (F1, Le Mans), you’ll want para-aramid fabrics from OEM-trusted names like:

These companies offer FIA and SFI-certified woven blends of para-aramid and Lenzing FR, often in dual-layer configurations, and ship globally to certified garment factories.

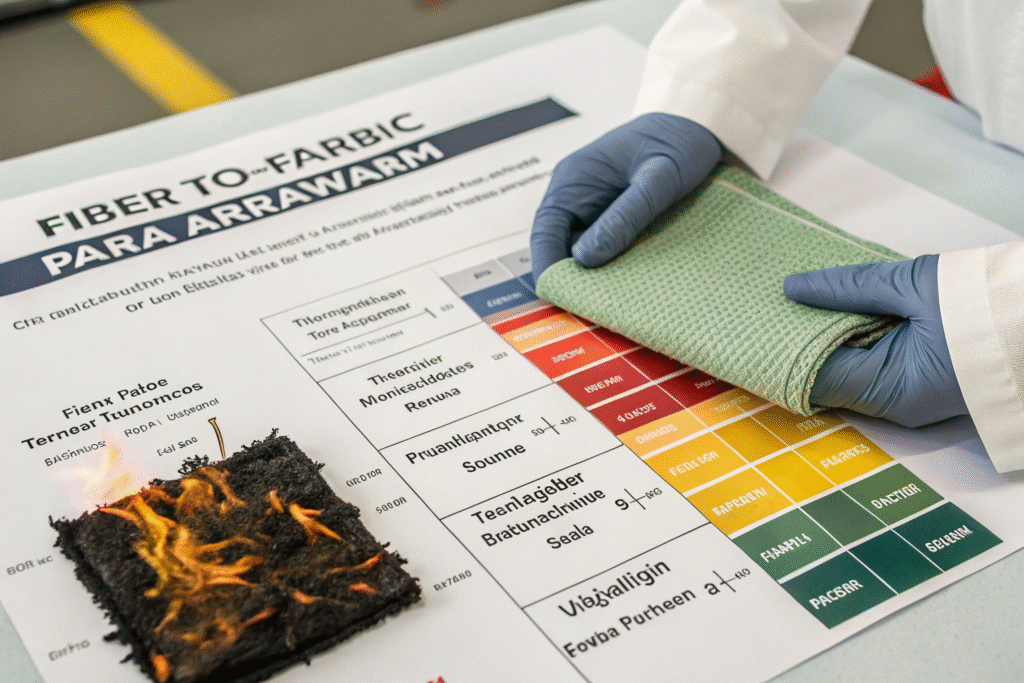

How Do You Evaluate Lightweight Racing-Grade Aramid Fabric?

Not all para-aramid fabrics are created equal. Before you commit to production, you’ll need verified data on grammage, durability, flame protection, and dimensional stability.

The key is matching fabric performance with racing suit certification standards and verifying third-party testing.

What Performance Metrics Should You Check?

Here’s what we typically evaluate at Fumao for racing-grade para-aramid fabrics:

| Property | Target Value | Test Method |

|---|---|---|

| Weight (GSM) | 140–170 gsm | ASTM D3776 |

| LOI (Limiting Oxygen Index) | >28% | ISO 4589-2 |

| Vertical Flame Resistance | <2 sec after-flame, <5 sec after-glow | ISO 15025 |

| TPP (Thermal Protection) | >6 cal/cm² | ASTM F2700 |

| Shrinkage (60°C wash) | <3% | ISO 6330 |

| Tear Strength | >15N (warp/weft) | ASTM D2261 |

Always request a full ISO 11612: A1, B1, C1 compliance report, and if your end buyer is in the U.S., ask for SFI 3.2A lab test reports.

Can You Customize Color or Stretch in Para-Aramid?

Yes. Para-aramid can now be solution-dyed (black, navy, red), which enhances UV stability. We also provide blended yarns with 3–5% spandex for greater mobility in elbows, knees, or inner layers.

Talk to our sourcing team for low-MOQ aramid-spandex interlocks, especially for karting suits or junior racing gear.

What Are the Common Applications for Lightweight Aramid in Motorsports?

Lightweight para-aramid isn’t just for Formula 1. Today, it’s widely used in karting, drag racing, endurance racing, and even electric motorcycle events, where agility and flame resistance are equally crucial.

Multi-layer racing suits, gloves, shoes, and balaclavas all benefit from the weight savings and durability of high-grade para-aramid.

What Garment Types Use Lightweight Para-Aramid?

- Outer Shells: Woven twill or ripstop for fire-blocking

- Inner Liners: Breathable interlock para-aramid for comfort

- Glove Backs: Heat-resistant knits with grip coatings

- Neck Shields: Lightweight 3D mesh laminates with para-aramid core

We also supply seam taping and binding edge fabrics in matching aramid blends for full-garment integrity.

Are There Hybrid Fabrics with Aramid Blends?

Yes—especially for cost control. Blends like Para-Aramid + Modacrylic, Aramid + FR Viscose, or Aramid + PBI offer different combinations of strength, weight, and flame protection.

If you're targeting budget racing brands or entry-level FIA suits, these blends are highly recommended. Many have EN ISO 11612 + ISO 13688 coverage and are more affordable per meter.

See Teijinconex blends for hybrid options used in fire gear and motorsports.

Conclusion

Finding lightweight para-aramid fabric isn’t just about ticking the “FR” box. It’s about sourcing the right fiber blend, weave construction, and weight class that aligns with your performance, compliance, and comfort goals.

At Fumao Fabric, we’ve helped global brands and factories develop racing-grade fabrics from raw aramid yarn spinning to final textile testing, including ISO and SFI documentation, cutting and lamination support, and custom color dyeing.

Need to source lightweight para-aramid for your next racewear line? Contact our Business Director Elaine at elaine@fumaoclothing.com and let us help you engineer faster, safer, and more breathable racing apparel from the fiber up.