The global demand for surgical gowns has surged in recent years—not just due to pandemic preparedness but also due to rising awareness around infection control. At the heart of high-performance medical textiles lies one gold standard: EN 13795 certification.

This European standard specifically outlines performance requirements for surgical drapes, gowns, and clean air suits, defining parameters to protect both patients and healthcare personnel from microbial transfer and fluid penetration.

If you're sourcing surgical gown fabrics or planning to enter medical PPE manufacturing, understanding EN 13795 is not just useful—it's mission-critical.

What Is EN 13795 and Why Should Fabric Buyers Care?

EN 13795 is a European harmonized standard that defines the barrier, cleanliness, and strength performance of fabrics used in surgical environments. It covers products that are either reusable or disposable, and it specifies performance by critical vs. less-critical zones of the surgical gown.

What Are the Key Criteria Defined by EN 13795?

EN 13795 outlines four main fabric performance metrics:

- Microbial cleanliness (bioburden control)

- Resistance to liquid penetration

- Resistance to microbial penetration (wet and dry)

- Bursting and tensile strength

It classifies surgical gowns into Standard Performance and High Performance based on test values.

Detailed criteria overview:

🔗 European Committee for Standardization (CEN)

🔗 EN 13795 Explained by Medtecs

Who Enforces or Requires EN 13795?

Although EN 13795 is a European norm, it's globally respected and referenced in:

- CE-marked medical PPE

- WHO procurement standards

- Tenders from EU hospitals

- Government and NGO emergency supply chains

Manufacturers outside Europe, including in China, Vietnam, India, and Mexico, regularly test fabrics to EN 13795 equivalency to gain buyer trust.

What Are the Fabric Testing Methods Under EN 13795?

EN 13795 testing is laboratory-based and quantitative. The test results decide if a fabric qualifies as “suitable for surgical use.”

What Laboratory Tests Are Mandatory?

-

Microbial Cleanliness

Test: EN ISO 11737-1

Pass if: ≤ 30 CFU/100 cm² -

Dry Linting (Particle Release)

Test: Helmke Drum Method

Pass if: ≤ 3.5 particles/cm² -

Resistance to Wet Microbial Penetration

Test: EN ISO 22610

Measured via Bacterial Barrier Index (BBI) -

Resistance to Liquid Penetration

Test: EN 20811 (Hydrostatic Head)

Threshold: ≥ 20 cm H₂O (Standard); ≥ 80 cm H₂O (High Performance) -

Tensile and Bursting Strength

Test: EN 29073-3 & ISO 13938-1

📘 Learn more about test methods at:

🔗 SGS Medical PPE Fabric Testing

🔗 Nelson Labs – EN 13795 Testing Services

How to Read the Results as a Buyer?

- “High Performance” gowns are used in long, fluid-intensive surgeries.

- “Standard Performance” is used for short, dry procedures.

- Always request third-party lab reports before bulk orders.

How Does EN 13795 Impact Material Selection?

Meeting EN 13795 isn’t just about testing—it starts with choosing the right base material and finish.

Which Fabrics Can Pass EN 13795?

| Material Type | EN 13795 Compliant? | Typical Use Case |

|---|---|---|

| SMS Non-woven (PP) | ✅ Yes | Disposable gowns |

| Laminated PP+PE | ✅ Yes | Fluid-intensive procedures |

| Polyester-cotton | ✅ Yes (if treated) | Reusable operating gowns |

| Spunlace viscose | ❌ Rare | Not durable enough for barrier use |

Fabric must balance strength, comfort, and lint control.

Explore material guides at:

🔗 Ahlstrom Medical Fabrics

🔗 Freudenberg Performance Materials

What Fabric Finishes Are Important?

- Antimicrobial finish (for reusable gowns)

- Antistatic coating (for cleanroom compatibility)

- Hydrophobic treatment (for splash resistance)

- Low-lint surface tech (for particle control)

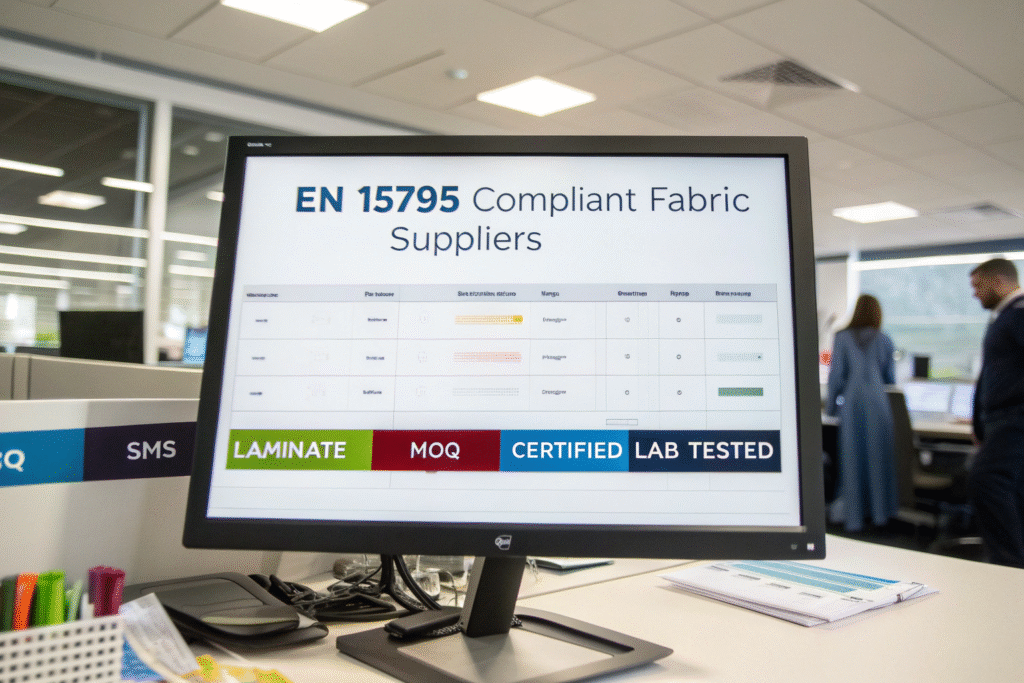

Where to Source EN 13795 Certified Surgical Gown Fabric?

The medical textile supply chain has matured to include lab-tested, certification-backed EN 13795 fabrics, especially from China, Korea, and Germany.

Which Suppliers Offer Certified Fabric?

- China (Suzhou, Hubei, Shandong) – Mass producers of EN 13795 SMS rolls

- South Korea – Clean-finish laminated gowns with antistatic options

- Germany – High-performance reusable gown fabrics

Search B2B marketplaces like:

🔗 Alibaba – EN 13795 SMS fabric

🔗 Made-in-China Medical Textiles

What to Ask Suppliers Before Ordering?

- Can you provide a valid EN 13795 lab report (from TÜV, SGS, Intertek)?

- Is the critical zone barrier rated as Standard or High?

- What’s the GSM, hydrostatic pressure, and CFU rating?

- Are custom roll widths or dyed variants available?

Request samples and test reports before committing to full container loads.

Final Thoughts

EN 13795 is more than just a CE marking requirement—it’s a trust standard for safety in surgery. With increasing government procurement scrutiny and hospital-level compliance audits, buyers who prioritize certified surgical gown fabric gain a competitive and regulatory edge.

Whether you’re sourcing for disposable medical kits or reusable protective wear, ensure your fabric meets EN 13795 standards from a certified supplier with proven lab documentation.

📩 For pre-tested EN 13795-compliant surgical gown fabric rolls or finished gown OEM services, contact FUMAO MEDICAL at elaine@fumaoclothing.com.