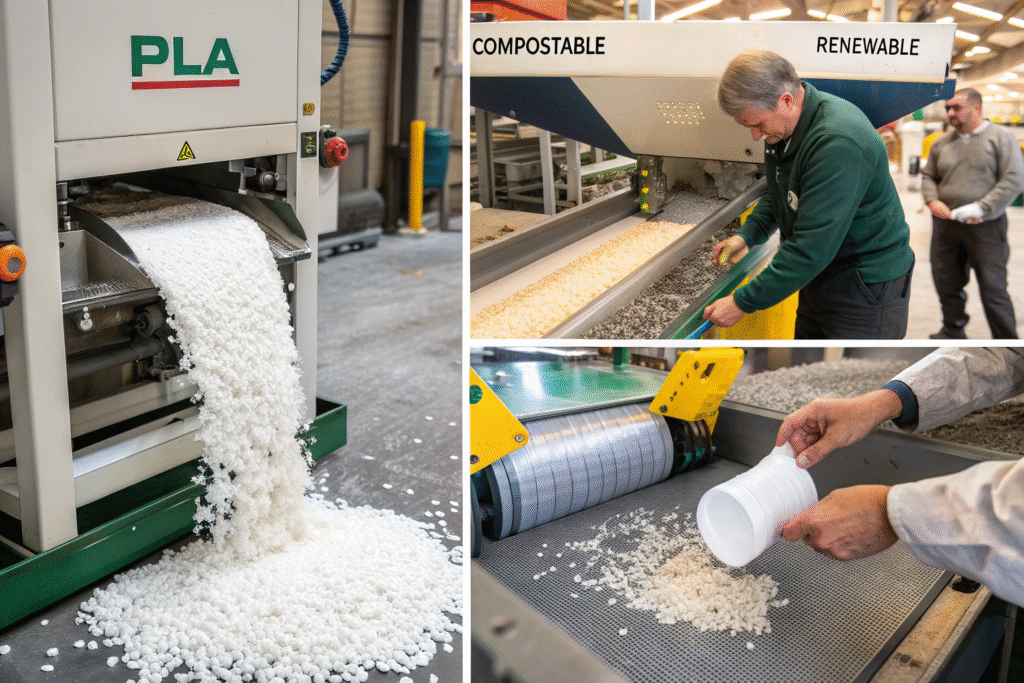

In a world rapidly shifting toward circularity, the demand for biodegradable alternatives to synthetic textiles is exploding—especially in non-woven applications like hygiene products, agriculture, packaging, and medical disposables. Enter PLA (polylactic acid) fused non-wovens—a bio-based, compostable material derived from plants like corn or sugarcane.

Biodegradable PLA fused non-wovens are thermally bonded fabrics made from renewable, compostable PLA fibers. They offer high breathability, softness, and moderate tensile strength—making them ideal for disposable and semi-durable applications.

Whether you're sourcing for wipes, wound dressings, baby care, or sustainable packaging, this guide shows you what to look for in high-quality PLA non-wovens, how to test them, and where to find certified suppliers.

What Are PLA Fused Non-Wovens and How Are They Made?

PLA (polylactic acid) is a biodegradable thermoplastic made from fermented plant sugars. In fused non-wovens, PLA fibers are melt-blown or spunbonded, then thermally bonded using heat or ultrasonic pressure—no chemical binders required.

The result is a lightweight, compostable fabric with excellent moisture management and biodegradability under industrial composting conditions.

What Are the Core Advantages of PLA Fused Non-Wovens?

- 100% bio-based and biodegradable

- Non-toxic, hypoallergenic

- High breathability

- Thermal stability up to 140°C

- Compostable in 60–90 days (EN 13432 / ASTM D6400)

More technical background available at NatureWorks Ingeo® and European Bioplastics.

How Is PLA Different from Conventional PP Non-Wovens?

| Property | PLA Non-Woven | PP Non-Woven |

|---|---|---|

| Source | Corn/Sugarcane | Petroleum |

| Biodegradable | Yes (Industrial) | No |

| Bonding Method | Thermal/Ultrasonic | Thermal |

| Composting Time | 60–90 days (PLA) | Non-compostable |

| Environmental Impact | Low CO₂ Footprint | High CO₂ + Plastic Waste |

Explore case studies at Bioplastics News and Mater-Bi by Novamont.

What Certifications Should You Look for When Sourcing PLA Non-Wovens?

Any supplier of PLA non-wovens worth partnering with should provide biodegradability, compostability, and safety certifications. These are essential for regulatory compliance and brand credibility.

Look for third-party validation from OK Compost, TÜV Austria, EN 13432, ASTM D6400, and ISO 17088.

Which Certifications Are Most Important?

| Certification | Meaning |

|---|---|

| OK Compost (TÜV) | Breaks down in 90 days industrially |

| EN 13432 | EU composting standard |

| ASTM D6400 | US compostable plastic test |

| ISO 17088 | Global biodegradability guideline |

| OEKO-TEX® Standard 100 | Skin safety and chemical safety |

Visit TÜV Austria's Compost Certification and ASTM biodegradability protocols for more.

Are SGS or Intertek Test Reports Useful?

Absolutely. While SGS or Intertek don’t issue compost certifications, they offer toxicity tests, heavy metal screening, biodegradation rate testing, and RoHS/REACH compliance.

Use labs like SGS Textile Services or Intertek Eco Testing to validate additional metrics.

Which Applications Use PLA Fused Non-Wovens?

Due to its gentle feel and compostability, PLA non-woven fabric is ideal for single-use or short-lifecycle applications that still require softness, breathability, and sustainability.

Industries using PLA fused non-wovens include hygiene, agriculture, medical, fashion packaging, and sustainable food services.

What Are Common Product Uses?

- Baby diapers & wet wipes

- Compostable shopping bags

- Wound care & medical pads

- Agricultural mulch film

- Tea bags & food pouches

- Eco mailers & inner packaging layers

Brands like Natracare and Avani Eco use PLA non-wovens in eco-disposables.

Can PLA Non-Wovens Be Laminated or Coated?

Yes. PLA can be laminated with bio-based coatings for barrier performance. It’s compatible with:

- Starch coatings

- Water-based polyurethane

- Breathable PLA films

- Cellulose coatings

See examples at NatureWorks packaging solutions and BASF ecovio®.

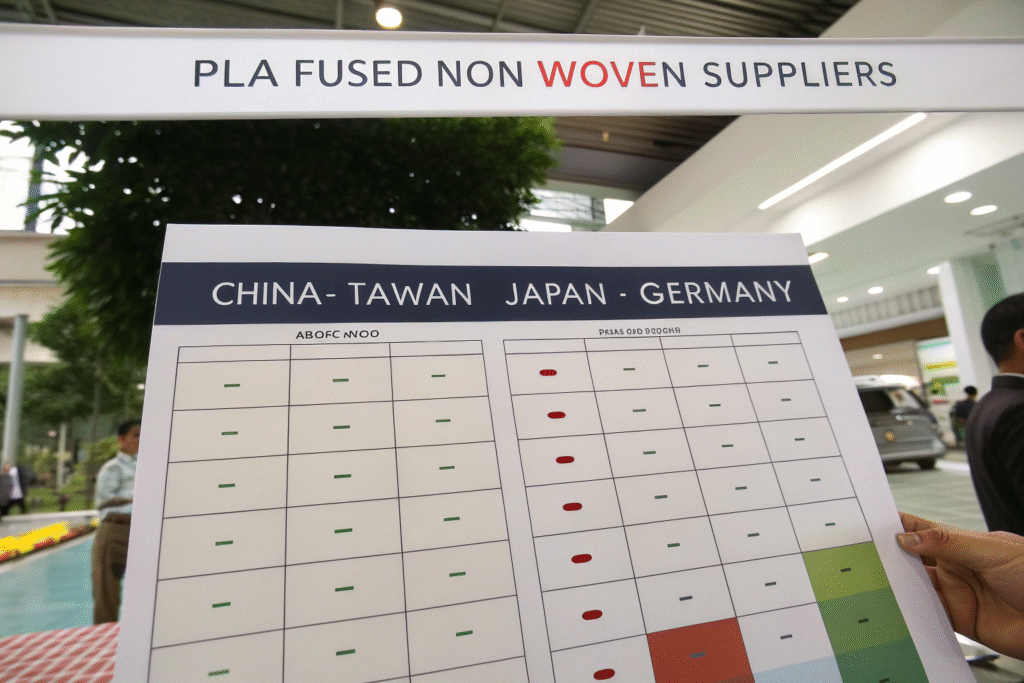

Where to Source PLA Fused Non-Woven Fabric?

Sourcing biodegradable PLA non-wovens requires filtering for quality control, fiber source verification, and process certifications.

Top manufacturing hubs include China (Zhejiang, Guangdong), Taiwan, Japan, Germany, and South Korea.

Who Are Reliable Suppliers?

- China: Hangzhou, Suzhou, Guangzhou – low-MOQ spunbonded PLA

- Taiwan: Advanced meltblown PLA filters

- Germany: High-end PLA composites for hygiene and packaging

- Japan: Bio-fusion technology + antibacterial finishes

Explore via:

Alibaba Biodegradable Nonwoven

Fibre2Fashion sustainable sourcing

GreenTrade.net

What to Ask Before Buying?

- Is it 100% PLA or blended with PP/PET?

- Can you provide TÜV OK Compost and EN 13432 certificates?

- What is the GSM and roll width?

- Is it needle-punched, meltblown, or spunbonded?

Also request lab sheets for toxicity, absorption, and fiber breakdown rate. Use QIMA or TÜV Rheinland for factory audits.

Conclusion

PLA fused non-wovens are a cornerstone of sustainable textile innovation. With true biodegradability, soft hand feel, and growing applications across hygiene, packaging, and agriculture, these materials are the future of eco-functional disposables.

At Fumao Fabric, we help global brands source TÜV-certified, 100% PLA fused non-woven fabrics with verified compostability and tailored weights. For packaging, medical use, or eco-wipes, contact our Business Director Elaine at elaine@fumaoclothing.com to request free samples or initiate custom development.