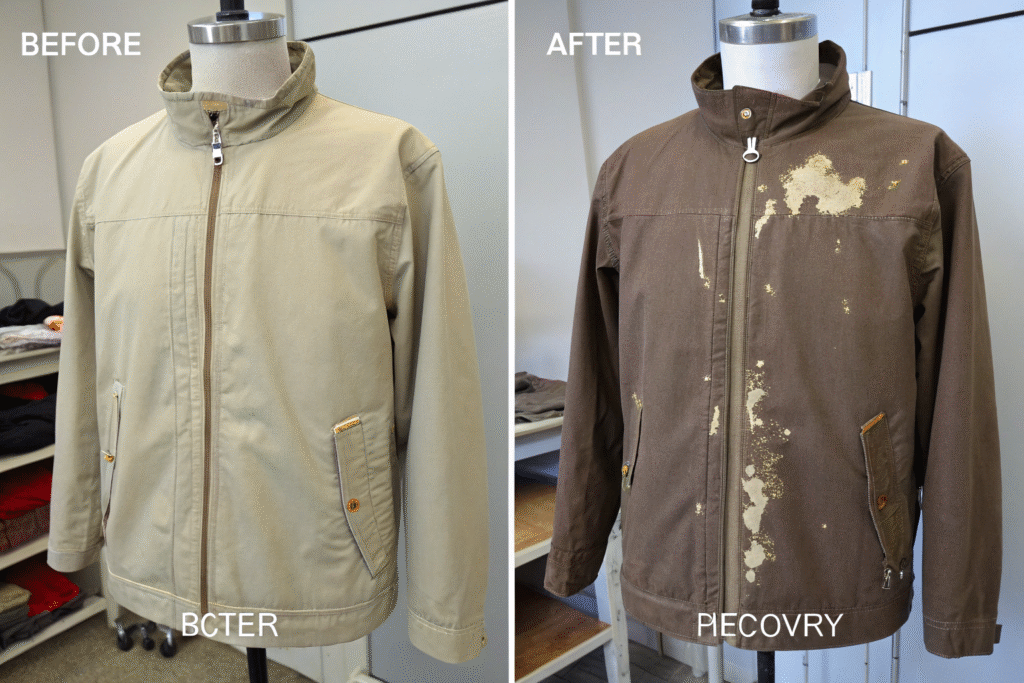

Fabric coatings have traditionally served as barriers—protecting against water, stains, and UV rays. But today, the frontier of textile innovation is evolving toward self-healing coatings—advanced materials capable of automatically repairing minor damage like cuts, abrasions, or punctures.

Recent developments in self-healing fabric coatings leverage microencapsulated polymers, dynamic bonds, and biomimetic chemistries to enable fabrics that restore integrity under heat, moisture, or friction—ideal for outdoor wear, military gear, and high-performance uniforms.

From consumer products to defense contracts, self-healing textiles are quickly transitioning from lab prototypes to scalable materials. Here's what fabric buyers and designers need to know.

How Do Self-Healing Fabric Coatings Work?

Self-healing coatings work by using reversible chemical bonds or microcapsules that activate when the fabric is scratched, torn, or abraded. When triggered by heat, pressure, or moisture, these materials reform their structure—essentially "healing" the fabric.

The two primary types of self-healing coatings are capsule-based systems (extrinsic) and reversible bond-based coatings (intrinsic).

What Are Extrinsic (Microcapsule-Based) Healing Systems?

These coatings contain microscopic capsules filled with healing agents like polyurethane or epoxy resins. When damaged, the capsules rupture and release the resin, which fills the scratch and polymerizes, restoring functionality.

Companies like Autonomic Materials Inc. and NEI Corporation lead in this area, originally developed for aerospace but now being adapted for fabrics.

How Do Intrinsic Self-Healing Coatings Work?

Intrinsic coatings rely on dynamic bonds—like hydrogen bonds, disulfide bridges, or Diels-Alder reactions—within the coating itself. When damage occurs, external stimuli (such as heat or humidity) allow the bonds to reconnect, "healing" without requiring a separate agent.

Materials developed by SRI International and EPFL's Soft Materials Lab show strong potential for apparel applications, particularly in wearable electronics and flexible gear.

Which Industries Are Leading in Self-Healing Fabric Applications?

While fashion is still catching up, industries like defense, aerospace, and outdoor equipment are pioneering use cases for self-healing textiles. These environments demand durability, long-term performance, and material longevity.

Military, high-performance sportswear, and protective equipment are currently the top sectors benefiting from self-healing fabric innovations.

What Applications Exist in the Military and Tactical Gear Space?

Self-healing coatings are integrated into bulletproof vests, tents, and rucksacks to prolong field durability. The U.S. Army’s Combat Capabilities Development Command is testing coatings that self-repair punctures in gas-permeable fabrics within 10 seconds.

Collaborations with Battelle Memorial Institute and DARPA have led to fieldable prototypes for chemical-resistant suits that can auto-seal after micro-perforation.

Is Outdoor Apparel Using These Technologies Yet?

Yes—early adopters like The North Face and Vollebak are experimenting with self-healing nylon and polyurethane coatings that re-seal under light friction or body heat. These materials are ideal for alpine jackets, expedition packs, and rainwear.

While costs remain high, some startups are now producing mid-range woven shells with Diels-Alder healing chemistry available for performance layering.

What Are the Limitations of Current Self-Healing Coatings?

Despite remarkable progress, current self-healing coatings face challenges: scalability, cost, fabric compatibility, and repair limitations (they can’t fix large rips or burned sections).

The most common drawbacks include limited healing cycles, loss of efficacy over time, and sensitivity to environmental triggers.

How Durable Are These Coatings After Repeated Washes?

Wash durability is one of the biggest concerns. While intrinsic systems (like reversible bonds) show better wash resistance, microcapsule systems often degrade after 20–30 wash cycles.

Textile Research Journal studies show that adding hydrophobic encapsulation or cross-linked PU barriers improves wash performance significantly.

Are These Coatings Compatible with Breathable or Stretch Fabrics?

Compatibility remains a hurdle. Many self-healing polymers stiffen the base fabric or reduce MVTR (moisture vapor transmission rate), making them unsuitable for activewear.

However, breakthroughs in elastic healing agents and thermoplastic elastomer blends from labs like Fraunhofer IFAM suggest improved stretch compatibility and breathability within 2–3 years.

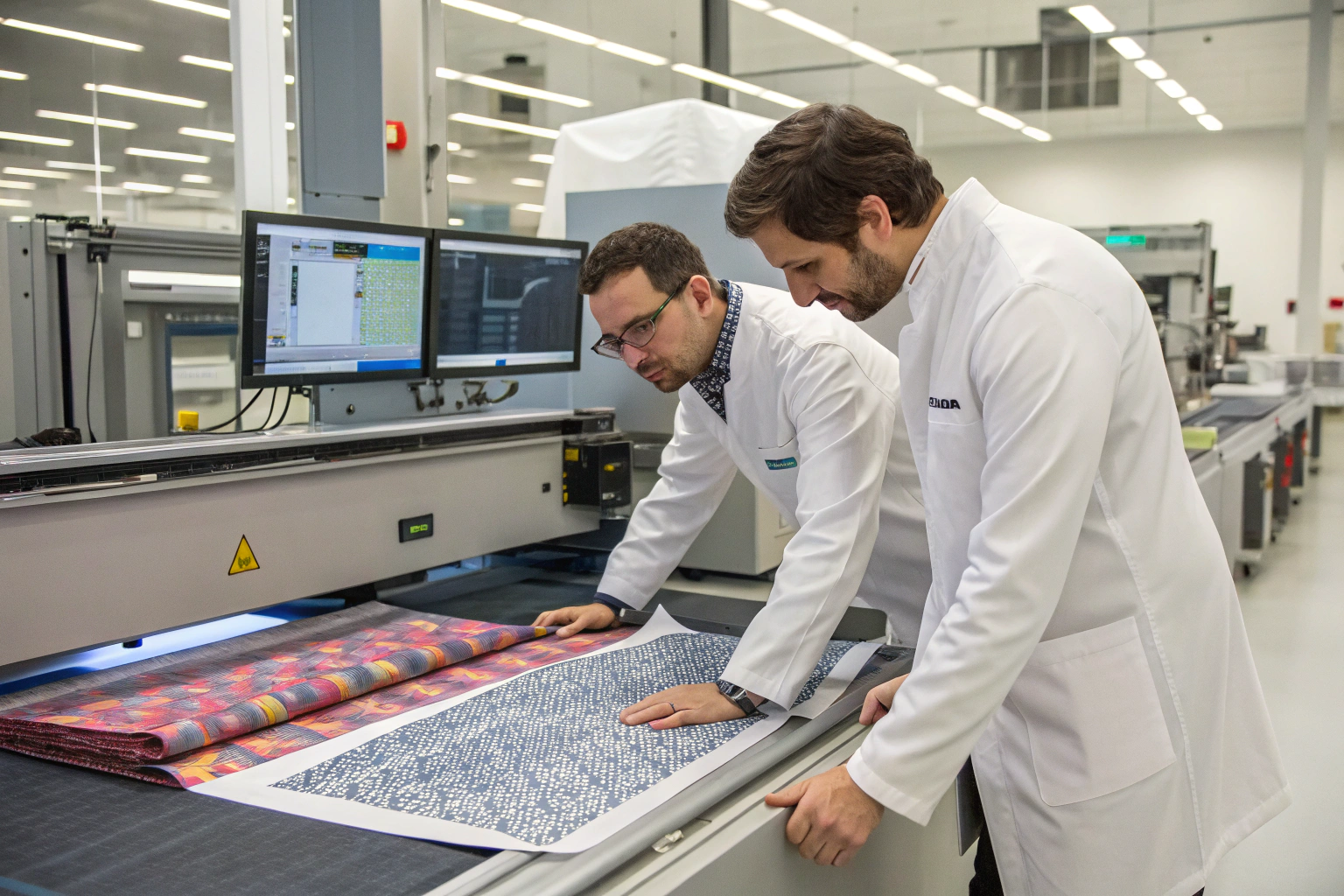

How Can Buyers Source Self-Healing Coated Fabrics?

Self-healing fabric coatings are still a niche product. Sourcing requires direct collaboration with innovation labs, material science startups, and specialty textile suppliers with coating capabilities.

To source effectively, buyers should validate healing performance, coating compatibility, and sustainability metrics through third-party testing and pilot-scale evaluation.

What Questions Should Buyers Ask Suppliers?

- What type of healing chemistry is used (capsule vs. intrinsic)?

- How many healing cycles are guaranteed?

- What triggers activation (heat, moisture, friction)?

- Is the coating breathable, washable, and abrasion-resistant?

Trusted suppliers include Swiss Textile Innovation AG and BASF R&D Partners, both of which offer pilot production runs for specialized apparel use.

Can Fumao Fabric Help Integrate These Coatings?

Yes. At Fumao, we partner with Chinese and international nano-coating innovators to develop low-MOQ self-healing finishes on technical base fabrics. Our process includes:

- CNAS lab validation of self-healing rate and durability

- Compatibility mapping with nylon, polyester, and softshell bases

- Custom finish thickness (3μm–10μm) for breathability retention

- Export-ready packaging with technical documentation

We can assist in sample yardage, testing, and co-developments tailored for performance fashion, workwear, or defense clients.

Conclusion

Self-healing fabric coatings represent the future of textile resilience—turning garments into intelligent materials capable of surviving real-world use. Whether you're developing outdoor gear, smart uniforms, or premium activewear, integrating self-repairing technology offers a functional and futuristic edge.

At Shanghai Fumao, we’re already helping forward-thinking brands integrate self-healing finishes onto woven and knit performance fabrics. From lab testing to coating customization, we deliver smart textile solutions designed to protect, last, and self-restore.

To start exploring self-healing coating options for your product line, reach out to our Business Director Elaine at elaine@fumaoclothing.com today.