In the competitive world of performance sportswear, breathability isn’t a luxury—it’s a necessity. For running apparel especially, air permeability plays a direct role in moisture regulation, body temperature control, and athletic performance. But how do you quantify "breathability"? That’s where air permeability ratings come in.

The optimal air permeability rating for running apparel fabrics typically ranges from 70 to 200 CFM (cubic feet per minute) depending on garment type, fabric thickness, and climate.

If you're sourcing running apparel or developing next-gen activewear, understanding air permeability is critical. Let’s break down how it’s tested, what “optimal” means, and how to choose the right rating for different use cases.

What Does Air Permeability Mean in Sportswear Fabrics?

Air permeability is the measure of how much air passes through a fabric in a given time. It is typically expressed in CFM (cubic feet per minute) or mm/s (millimeters per second) under a standardized pressure. It determines how breathable a fabric feels during activity.

In running apparel, higher air permeability allows heat and sweat vapor to escape, keeping athletes cooler, drier, and more comfortable over longer distances.

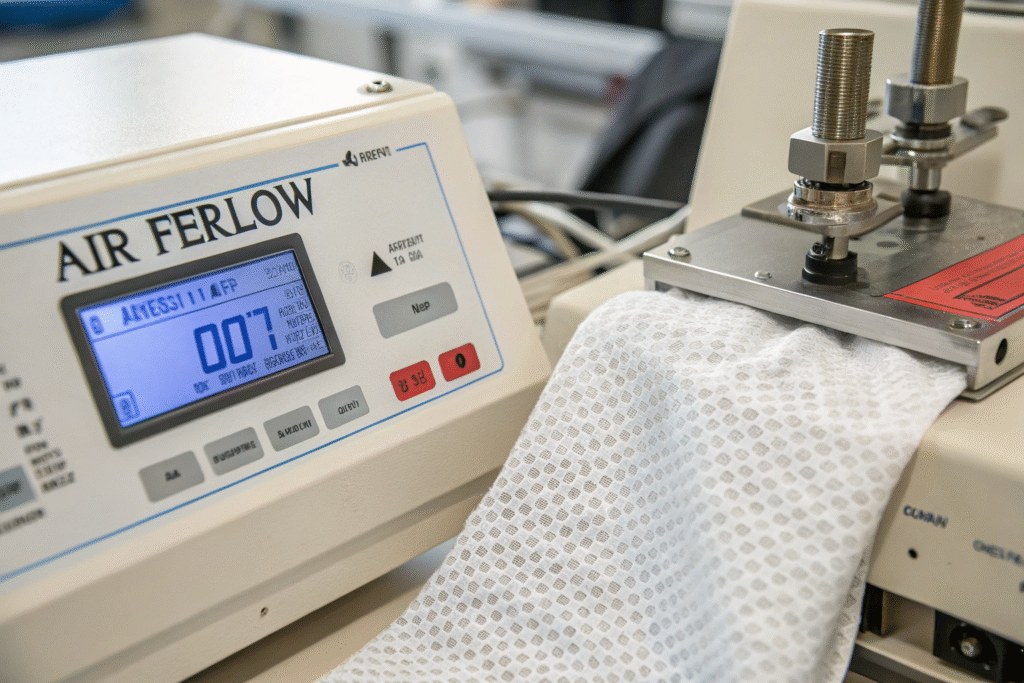

How Is Air Permeability Measured?

The standard method is ASTM D737 or ISO 9237, where fabric is clamped into a chamber and air is forced through it. The machine then records how much air (in CFM or L/m²/s) passes through under a specific pressure differential.

Detailed test protocols are explained by Intertek and SGS.

Why Does It Matter for Running Gear?

Running generates continuous sweat and heat. If the fabric traps air, it causes overheating, discomfort, and chafing. High air permeability fabrics like mesh or engineered knits help wick moisture, release heat, and improve endurance.

Studies by Hohenstein Institute have shown that garments with air permeability above 90 CFM increase user comfort significantly during aerobic exercise.

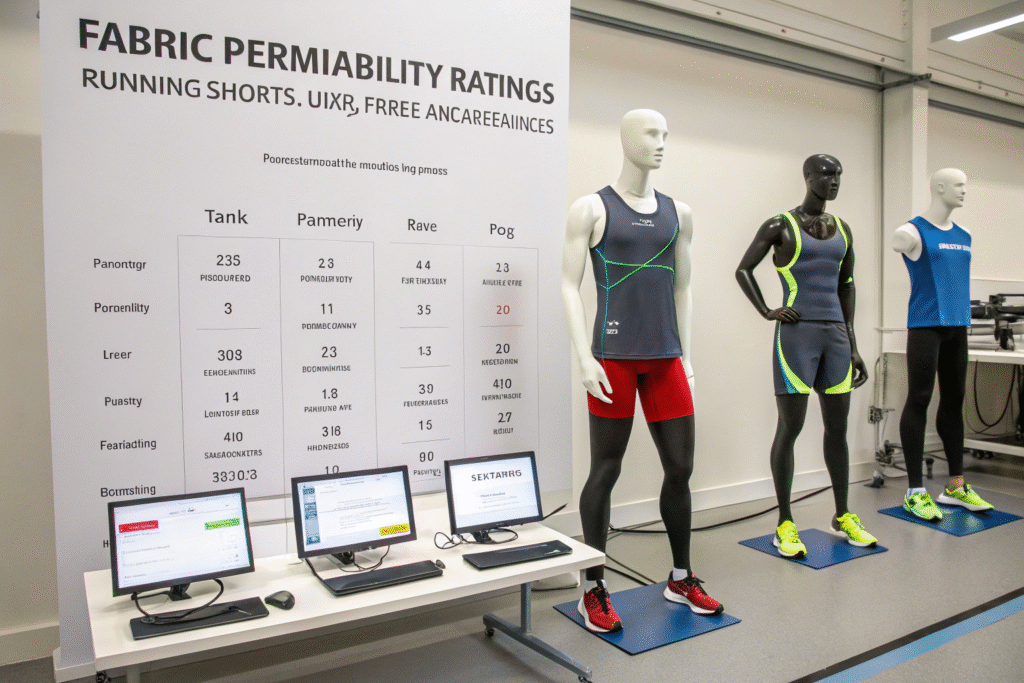

What Are Ideal Air Permeability Ranges by Garment Type?

Not all running garments require the same breathability. Tank tops need higher airflow zones at the chest and back, while compression leggings require moderate permeability to balance sweat management and support.

Here’s a general guide for optimal air permeability ratings in running apparel:

What Is the Best Air Permeability for Running Tops?

- Lightweight race singlets: 150–200 CFM

- Standard training shirts: 100–150 CFM

- Layered mesh zones (back panels, underarms): 200+ CFM

Brands like Nike Dri-FIT ADV and Adidas HEAT.RDY use highly breathable warp-knit meshes in high-heat zones to maximize performance.

What About Running Tights or Compression Gear?

- Compression tights: 40–80 CFM (to maintain structure)

- Ventilated running shorts: 120–180 CFM

- Base layers: 70–120 CFM

At Fumao Fabric, our power mesh blends with 75% polyamide and 25% elastane deliver 80 CFM at 180 gsm, ideal for next-to-skin applications that require both stretch and breathability.

You can review similar ranges via Eurojersey Sensitive Fabrics or Polartec’s Fabric Selector.

How to Balance Air Permeability with Other Fabric Properties?

Breathability is essential, but it must work in harmony with other critical properties—stretch, moisture-wicking, and durability. A fabric that is too porous might lose shape or lack sufficient UV protection or abrasion resistance.

Smart running fabric sourcing means optimizing—not maximizing—air permeability while preserving garment performance in motion.

What Fabric Blends Provide the Best Balance?

Fabrics that score well in air permeability and other properties include:

- Micro-perforated polyester/elastane with hydrophilic wicking finishes

- Warp-knit power mesh with bonded seams

- Jacquard-engineered zones that provide airflow in high-sweat areas

At Fumao, we’ve developed digital zone-mapped fabrics that combine 150+ CFM venting areas with <50 CFM compression bands—ideal for marathon or ultra-trail running kits.

Explore further tech specs from Toray Advanced Textiles or Schoeller Textiles.

Does Higher Air Permeability Always Mean Better Comfort?

No. In cold or windy climates, high air permeability may lead to heat loss. In such conditions, moisture-wicking plus thermal retention is preferred. Ideal fabric selection varies by climate, user intent, and run duration.

Combining fabric data with climate maps and athlete feedback creates the best outcome. Wear trials backed by real-time skin temp and sweat loss sensors (like those used in GORE Wear Labs) help validate lab results.

How to Source and Test Air Permeable Fabrics for Running?

Finding breathable fabrics isn't just about ordering mesh. It requires a structured approach to fiber sourcing, lab testing, and performance simulation under dynamic load.

To source the best fabrics, work with suppliers offering lab-tested air permeability data, fabric customization, and integration with your garment tech pack.

What Are the Key Questions to Ask Your Fabric Supplier?

- Can you provide ASTM D737 or ISO 9237 test results?

- What’s the CFM rating at 125 Pa pressure?

- Are air permeability and MVTR (moisture vapor transmission rate) both tested?

- Can you adjust fabric weight or mesh ratio for specific airflow targets?

At Fumao, all performance knits undergo CNAS-certified testing. We offer adjustable mesh constructions from 90–210 CFM, with custom dyeing, digital printing, and seam taping options.

Can You Simulate Breathability Before Production?

Yes. Virtual sampling tools like Browzwear and CLO 3D allow brands to simulate airflow and moisture dynamics in 3D garments. When combined with real lab data, these tools speed up prototyping and reduce waste.

We support this with virtual fabric profiles and air permeability heatmaps for all Fumao performance fabric lines—ideal for digital-native brands or DTC launches.

Conclusion

Air permeability is the silent hero of high-performance running apparel. It determines whether your garment cools the runner, clings with sweat, or holds its shape during peak output. Understanding optimal air permeability ratings—and how to source fabrics that meet them—sets your brand apart in today’s performance-driven market.

At Shanghai Fumao, we work with global brands to develop breathable, durable, and test-backed running fabrics ranging from 70 to 220 CFM. Whether you need light mesh tops, compression leggings, or zone-engineered knits, we offer fabric testing, customization, and international delivery.

To request breathable fabric swatches or collaborate on performance garment development, contact our Business Director Elaine at elaine@fumaoclothing.com today.