Aerogel, one of the world’s lightest and most effective insulation materials, was once confined to NASA space missions and Mars rovers. Today, this cutting-edge material is making its way into extreme weather clothing, aerospace wear, and even technical sportswear.

To find NASA-developed aerogel insulation fabric, brands and buyers must identify licensed manufacturers like Aspen Aerogels, Aerotherm, and flexible composite suppliers that specialize in breathable, durable aerogel textiles.

Whether you’re sourcing for arctic expeditions, high-performance apparel, or defense-grade outerwear, this guide outlines everything you need to know about aerogel fabric sourcing, testing, and commercial applications.

What Is Aerogel Insulation Fabric and How Does It Work?

Aerogel is a porous structure made by replacing the liquid in a gel with gas, creating a matrix of 99% air and silica. It has the lowest thermal conductivity of any known solid. When incorporated into fabrics, aerogel provides unmatched insulation at minimal thickness.

Aerogel insulation fabric uses embedded aerogel particles or coatings within a textile matrix to trap heat and block cold, making it ideal for extreme environments.

What Are the Key Properties of Aerogel in Textile Form?

- Ultra-lightweight: Aerogel weighs just 3–150 kg/m³

- High thermal resistance: R-values exceed traditional insulation by 3–4x

- Thin & flexible: Thickness as low as 2 mm

- Hydrophobic & breathable (when laminated with breathable membranes)

- Fire-resistant & non-toxic

Leading versions include Spaceloft® by Aspen Aerogels and Cryogel Z for cryogenic clothing.

How Is NASA Involved in Aerogel Fabric Development?

NASA pioneered silica aerogels for thermal shielding during space missions, using them in Mars rovers and astronaut suits. Commercial spin-offs have since licensed the technology to textile innovators. See NASA’s tech transfer page on Aerogel Technology.

NASA’s partnerships with private firms like Aspen Aerogels and Blachford helped commercialize flexible versions used in defense and industrial garments.

Which Manufacturers Offer Aerogel Textile Composites?

Finding aerogel fabrics requires working with advanced material manufacturers, not conventional apparel mills. These companies combine aerogel with laminates, nonwovens, or scrims to create usable, sewable insulation composites.

Top sources include Aspen Aerogels (USA), TAASI (Korea), Aerogel Technologies (USA), and selected Chinese labs partnered with thermal R&D platforms.

Who Are the Leading Global Suppliers?

- Aspen Aerogels – Their Spaceloft® product is widely used in aerospace, outerwear, and military gear.

- TAASI Korea – Manufactures breathable and thin aerogel insulation layers for jackets and gloves.

- Aerogel Technologies – Specializes in ultra-flexible aerogel sheets and composites.

- Lydall Performance Materials – Offers thermal and acoustic insulation panels that include aerogel options.

These suppliers generally serve B2B industrial, defense, or performance textile markets.

Can Chinese Factories Produce Aerogel Fabrics?

Yes. While aerogel particles are often imported, several Chinese factories—including those partnered with Fumao Fabric—now embed aerogel into nonwovens or laminated insulation pads using breathable PU or TPU layers. These are suitable for cold-weather jackets, expedition suits, and heat-resistant outerwear.

We’ve worked with domestic R&D centers that offer 2–10mm thickness aerogel-insulated pads with outer face fabric options (nylon, softshell, etc.). Contact us to learn about sourcing these composites with CNAS lab reports.

How to Test Aerogel Insulation Fabric Performance?

Testing aerogel fabric isn’t just about loft or feel—it’s about performance under extreme temperature and moisture conditions. Proper testing ensures your sourced fabric meets real-world needs.

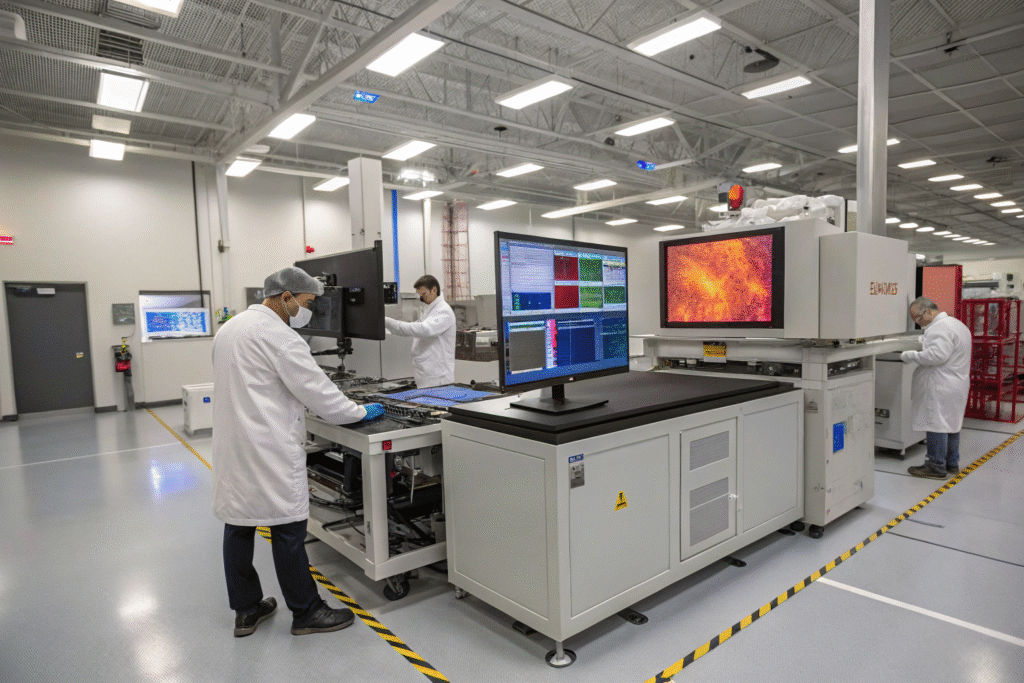

Aerogel insulation fabric is tested for thermal conductivity (ASTM C518), R-value, water resistance, breathability (MVTR), flame retardancy, and compression recovery.

What Lab Tests Are Used to Evaluate Aerogel Fabrics?

- Thermal conductivity: Measured in W/m·K (ASTM C518 or ISO 8301)

- Moisture Vapor Transmission Rate (MVTR): ISO 15496 or ASTM E96

- Flame resistance: EN ISO 11612, ASTM D6413

- Compression Set: ASTM D3574 for recovery after pressure

- Hydrostatic head: Water resistance of outer layers

Labs like SGS, TÜV SÜD, and Intertek offer fabric certification packages tailored for high-performance insulation.

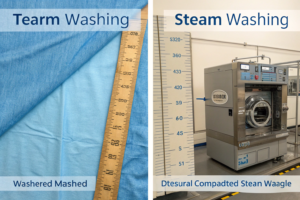

Can Aerogel Fabrics Be Washed or Laminated?

Some can. Classic aerogels are brittle, but modern formulations like Aspen’s Spaceloft® or TAASI’s products use flexible composites. Laminating these between breathable membranes or quilting them with outer fabrics allows for limited washability (often hand-wash only or dry-clean recommended).

Always confirm lamination type and handling instructions before production. At Fumao, we offer water-resistant PU laminations and seam-taped configurations with up to 3K breathability.

What Are the Top Applications for Aerogel Textiles?

Aerogel insulation fabric is not for casual T-shirts. It’s used where every gram counts and where the cold—or heat—is extreme. From aerospace to urban winter sports, it offers an edge few materials can match.

Top uses for aerogel insulation fabric include mountaineering suits, arctic workwear, military field gear, space industry clothing, and elite outdoor apparel.

What Apparel Categories Benefit Most?

- Arctic expedition suits and parkas

- Aerospace technician coveralls

- Rescue team outerwear and boots

- Cold-chain delivery uniforms

- Technical cycling, skiing, and snowboarding gear

Brands like Vollebak and The North Face have experimented with aerogel panels in outerwear to reduce bulk and enhance performance.

Can You Order Aerogel Fabrics in Small Quantities?

MOQ is often high (500m+), but Fumao Fabric offers pilot yardage options for testing and sampling. We also stock aerogel-laminated insulation sheets in 2mm–10mm for low-volume prototyping and capsule collections. Custom options for nylon + aerogel + mesh can be produced within 35 days.

We support designers working on Kickstarter techwear, military gear contractors, and industrial PPE innovators.

Conclusion

Aerogel insulation fabric is no longer just a NASA secret—it’s a next-gen textile solution now available to apparel developers and sourcing teams worldwide. From unmatched thermal resistance to ultra-light performance, aerogel-infused fabrics are reshaping cold-weather and technical clothing.

At Shanghai Fumao, we help global buyers source flexible aerogel fabric systems that meet ASTM, ISO, and EN standards—ready for real-world production. Whether you're building cold-climate workwear or futuristic outerwear lines, we’ll support your development with lab-tested, production-ready materials.

To explore our aerogel composite offerings, request swatches, or inquire about custom orders, contact our Business Director Elaine at elaine@fumaoclothing.com.