Create a hyper-realistic image of a female athlete wearing a biometric sensor-fitted sports bra during a treadmill run in a textile testing lab. Include motion capture equipment, pressure sensors, and fabric stretch visuals. Avoid facial distortion and any embedded text or maps.

Biometric testing is essential for developing sports bra compression fabrics because it provides real-time data on pressure distribution, breast movement, and fabric recovery—helping brands design garments that actually perform under strain.

For apparel brands serious about functionality and biomechanics, relying solely on lab tensile tests or marketing claims is no longer enough. Let’s explore how biometric testing is redefining smart compression fabric design in sports bras.

What Is Biometric Testing in Activewear Fabric Development?

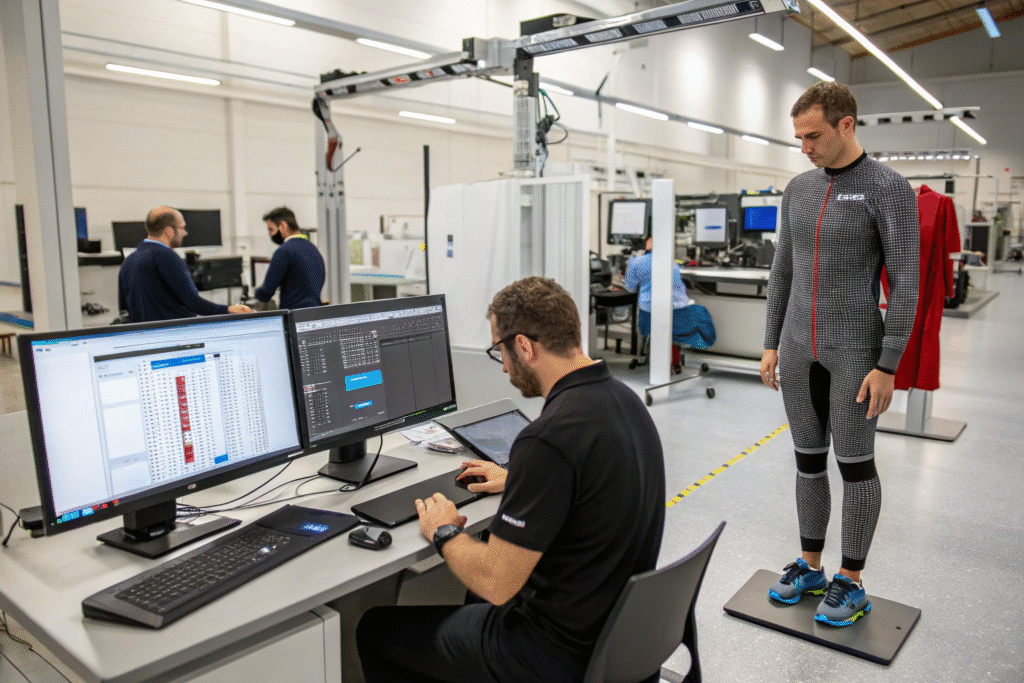

Biometric testing refers to the use of wearable sensors and movement analysis to study how fabric interacts with the human body during activity. It’s widely used in sports science, but is now transforming fabric R&D—especially in compression garments.

When applied to sports bra fabrics, biometric testing allows designers to measure motion zones, pressure points, elasticity response, and bounce reduction in real-time during high-impact activity.

How Are Sensors Used to Evaluate Compression Fabrics?

Advanced tools like Tekscan and Xsens motion capture use pressure and 3D motion sensors to track breast movement and fabric response across multiple zones. The data collected includes:

- Peak compression pressure in mmHg

- Directional breast displacement in mm

- Fabric elongation/recovery under stretch

- Time-lag in fabric bounce-back

This allows developers to pinpoint where a fabric fails to support or compress effectively, even under dynamic conditions.

Why Is This Different from Standard Lab Testing?

Traditional tensile tests (e.g., ASTM D4964) measure fabric elongation and recovery in static settings. However, a sports bra moves in multiple dimensions—under strain, sweat, and high-speed bounce. Biometric testing captures these dynamic stress points, ensuring compression fabrics perform beyond the lab.

See comparative testing setups on Intertek’s Performance Textile Services and Hohenstein’s 3D body simulation lab.

What Fabrics Perform Best in Biometric Compression Testing?

Not all compression fabrics are created equal. Some deliver stretch but lack rebound. Others compress well but chafe. Biometric data helps determine which fabric structures and blends offer ideal support across all body sizes and motion intensities.

Top-performing compression fabrics often combine high-gauge circular knitting, nylon-spandex blends, moisture control, and directional elasticity.

Which Fabric Structures Deliver Consistent Support?

Warp-knit fabrics and double-layer circular knits outperform plain jerseys in biometric testing. They offer better multi-directional support with minimal stretch fatigue. Common options include:

- Nylon/Spandex Power Mesh

- Double-face Polyamide Compression Knit

- Spacer Mesh with bonded lining

You can compare fabric specs on Schoeller Textiles or Eurojersey's Sensitive® Fabrics.

How Does Fiber Content Affect Biometric Feedback?

Nylon-based fabrics tend to provide better support and moisture wicking than polyester in biometric compression maps. However, adding micro-denier polyester or Tactel® enhances softness and recovery.

At Fumao Fabric, we’ve benchmarked fabrics with varying elastic modulus and found that blends with 18–24% Lycra content and over 250 gsm offer optimal bounce control across cup sizes B to E.

How Does Biometric Testing Improve Sports Bra Fit Across Sizes?

Fit is the #1 pain point in sports bras. A bra that works for a size B cup may utterly fail for a size D. Biometric testing allows developers to scale fabric compression patterns to support diverse body shapes and reduce discomfort.

By using biometric mapping, brands can calibrate compression levels by cup size, adjust panel placement, and design adaptive fit systems using zoned fabrics.

What Metrics Are Used to Adjust Fit by Size?

- Vertical and lateral breast displacement (in mm)

- Dynamic pressure zones (in mmHg)

- Skin shear resistance (friction mapping)

- Fabric stretch limits by zone

These metrics can be translated into zoned patterning and graded stretch levels in sports bras. Tools like BodiTrak and Hohenstein’s Ergonomic Modeling assist in modeling.

Are There Brands Using Biometric Fit Data Now?

Yes. Leading brands like Under Armour and Nike already use sensor-based product development to refine fit and bounce control in their high-impact sports bras. Startups like SheFit and Knix are also adopting biometric panels to create inclusive sizing systems.

At Fumao, we’ve collaborated with performancewear brands on sports bra collections using dynamic fit zones and variable tension stitching—backed by biometric feedback.

How Can Manufacturers Implement Biometric Testing in Development?

Integrating biometric testing into fabric development requires collaboration between textile engineers, sports scientists, and product designers.

The process includes sample preparation, sensor calibration, wearer testing, motion capture, data analysis, and iteration on fabric type, stretch ratio, and sewing technique.

What Equipment and Facilities Are Needed?

Key tools include:

- Wireless pressure sensors and stretch strain gauges

- 3D motion capture (like Xsens)

- Biometric mannequins (e.g., Avalution)

- Real-wear test environments (e.g., treadmill lab, heat chamber)

Many testing centers now offer lab-as-a-service models, including Hohenstein and NILIT Labs.

Can Fumao Fabric Offer Biometric-Informed Development?

Yes. At Fumao, we:

- Collaborate with CNAS-certified test labs in China

- Benchmark fabric stretch, pressure, and thermal mapping across body types

- Offer digital tech packs based on biometric data

- Provide zoned fabric swatches and custom elastane blends for high-impact bras

- Support low MOQ development for boutique brands and high-volume runs

We also offer virtual sampling and avatar-based motion fit simulations to speed up prototyping and improve bounce control for your next bra collection.

Conclusion

Biometric testing is not just a research tool—it’s a competitive advantage. As women demand more from activewear, compression fabric must evolve from soft-stretch basics to data-driven innovation. With biometric testing, your fabric choices become smarter, more targeted, and more inclusive.

At Shanghai Fumao, we help global brands create performance-ready sports bra fabrics powered by real-world data. From lab testing to yarn development to international delivery, we’re your trusted partner in smart textile sourcing.

To request compression fabric swatches or book a biometric-backed development consultation, contact our Business Director Elaine at elaine@fumaoclothing.com today.