As environmental regulations tighten across the globe, buyers, importers, and brands are under growing pressure to ensure their fabrics are free from harmful substances—particularly PFAS, often called “forever chemicals.” These substances are widely used in textiles for their water and stain resistance, but their persistence in the environment and human body makes them a major health concern.

To test fabric for PFAS contamination, brands should use standardized analytical methods like LC-MS/MS or FTIR spectroscopy in accredited labs. They must also request certificates of analysis and work with trusted suppliers to ensure compliance.

If you're sourcing fabrics from China or Southeast Asia, especially with waterproof or oil-repellent finishes, there's a high chance PFAS might be involved. Understanding how to detect and avoid them is essential for passing customs, avoiding liability, and protecting brand reputation.

What Are PFAS and Why Are They in Fabrics?

PFAS—short for per- and polyfluoroalkyl substances—are a family of over 10,000 synthetic chemicals. Known for their water, grease, and stain resistance, PFAS are frequently used in functional textiles.

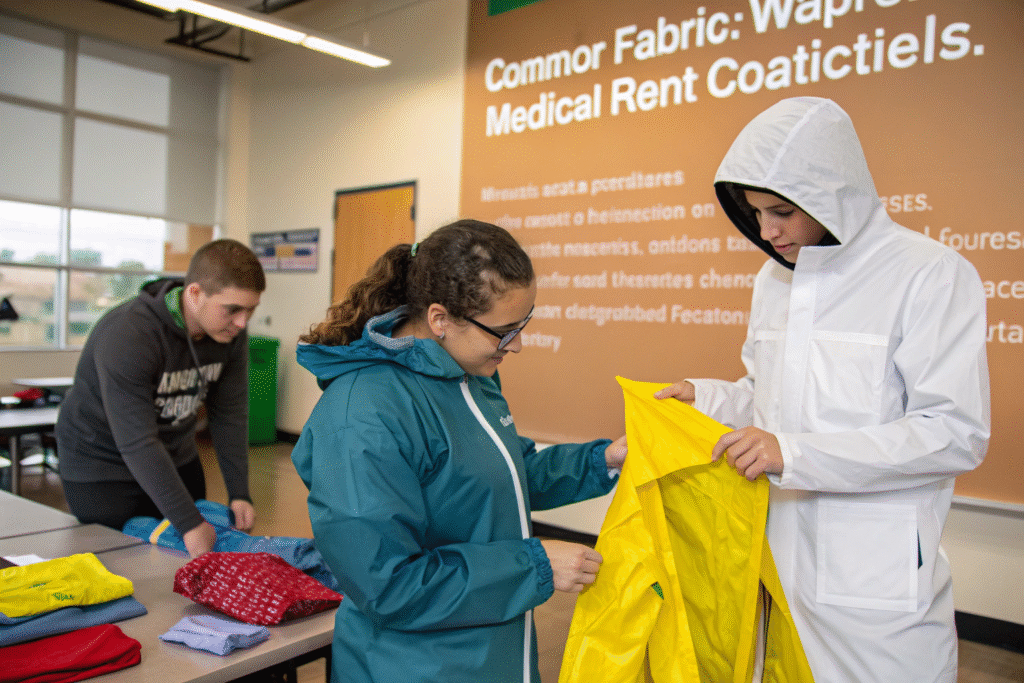

Many fabrics used in rainwear, uniforms, upholstery, and athletic gear contain PFAS-based coatings to make them hydrophobic or oil-repellent.

What Are the Health Risks of PFAS in Clothing?

PFAS don't break down easily in nature. Some types can stay in the environment—and our bodies—for years. Exposure has been linked to cancer, hormone disruption, liver damage, and developmental issues. Studies by the U.S. Environmental Protection Agency (EPA) and the Centers for Disease Control (CDC) have raised significant concerns.

For brands importing fabric into the U.S. or EU, presence of PFAS could trigger customs rejections or product recalls under green regulations.

Which Fabric Types Are Most Likely to Contain PFAS?

While natural fibers like cotton or linen rarely contain PFAS, synthetic-based textiles like polyester and nylon blends with durable water repellent (DWR) finishes are common culprits. Performance garments marketed as water-proof, stain-resistant, or wrinkle-free often use these chemicals.

High-risk items include outerwear, mattress covers, stain-resistant upholstery, and medical textiles—especially when sourced from suppliers lacking clear certifications or third-party test reports.

Which Testing Methods Are Used to Detect PFAS in Fabric?

Detecting PFAS is technically complex. Since there are thousands of PFAS variants, labs need to focus on regulated or high-risk ones like PFOA, PFOS, or GenX.

The most common PFAS testing methods in textiles include LC-MS/MS (Liquid Chromatography–Mass Spectrometry) and TOF-SIMS (Time-of-Flight Secondary Ion Mass Spectrometry).

How Does LC-MS/MS Work for PFAS Testing?

This method identifies PFAS molecules by separating them in liquid chromatography and then weighing them with mass spectrometry. It’s highly accurate and widely used in compliance testing, especially for OEKO-TEX and ZDHC MRSL compliance.

Labs using LC-MS/MS can detect PFAS concentrations as low as parts per trillion (ppt), which is critical when complying with U.S. state-level bans like California’s AB 1817.

Are There Cost-Effective Alternatives to Lab Testing?

Yes—screening tools like FTIR (Fourier-transform infrared spectroscopy) and portable XRF analyzers offer quick, non-destructive detection of fluorine bonds, which could indicate PFAS presence. While not as accurate, they’re useful for supplier screening or QA checks.

Still, only third-party lab reports with certified PFAS panels will satisfy major import regulations and client requirements. Several testing houses like SGS and Intertek offer packages tailored for textile buyers.

What Certifications Guarantee PFAS-Free Fabrics?

Many buyers mistakenly believe “green” fabrics are always PFAS-free. That’s not always the case unless specifically certified.

Certifications like OEKO-TEX Standard 100, GOTS, and bluesign® offer the highest assurance that textiles are free from PFAS and other harmful chemicals.

What Should You Look for in Supplier Certifications?

Always ask suppliers for third-party verified certifications. A declaration from the supplier isn’t enough—PFAS may still be present unintentionally. Look for batch-level testing, compliance with REACH, and compatibility with ZDHC MRSL V3.1.

Platforms like Texbase or Testex help buyers verify authenticity and manage compliance across multiple vendors.

How Can You Ensure Certifications Are Up to Date?

All certificates have validity periods. Ask for recent test reports—ideally no older than 12 months. You can also cross-check lab-issued certificates directly with the issuing body, or use QR-based traceability tools if the supplier supports them.

At Fumao Fabric, we integrate CNAS lab reports and QR tracking for every certified shipment, and we work with Intertek and SGS for PFAS and heavy metal testing upon request.

How to Work with PFAS-Free Suppliers in China?

Choosing a reliable partner is key if you want to ensure fabric safety.

A trusted supplier should offer not only certificates but also transparency into their finishing processes and access to non-PFAS alternatives like C6-free DWR coatings.

What Questions Should You Ask Potential Suppliers?

Here are a few key questions to help you screen suppliers for PFAS safety:

| Question | Why It Matters |

|---|---|

| Do you use any C8 or C6-based water repellents? | PFAS exposure risk |

| Can you provide third-party PFAS test reports? | Verification |

| What sustainable DWR alternatives do you use? | Safety & performance |

| Are you bluesign® or OEKO-TEX certified? | Compliance check |

Suppliers unable to answer these confidently may not have clear process control or testing capabilities.

How Does Fumao Fabric Ensure PFAS Compliance?

At Fumao, we’ve moved 90% of our water-repellent fabrics to C0 fluorine-free finishes. All such products can come with SGS or Intertek reports on request. Our lab in Keqiao is CNAS-certified and continuously updates to match ZDHC Gateway protocols.

We also help clients choose between PFAS-free DWR or bio-based wax coatings based on cost-performance needs. For buyers shipping to the U.S., we offer technical file assistance to meet AB 1817 and Maine PFAS law requirements.

Conclusion

As regulatory pressure grows globally—especially in the U.S. and Europe—textile buyers cannot ignore PFAS. From lab testing with LC-MS/MS to verifying OEKO-TEX or bluesign® certifications, understanding how to test and select PFAS-free fabrics is essential for compliance, customer trust, and sustainable brand positioning.

At Shanghai Fumao, we go beyond selling fabric—we help you build a safer, compliant supply chain. Whether you’re producing outerwear, uniforms, or sustainable activewear, our team is ready to offer lab testing, QR-based batch tracking, and custom coating solutions.

Reach out to our Business Director Elaine at elaine@fumaoclothing.com to discuss your next fabric order with guaranteed PFAS compliance and transparent documentation.