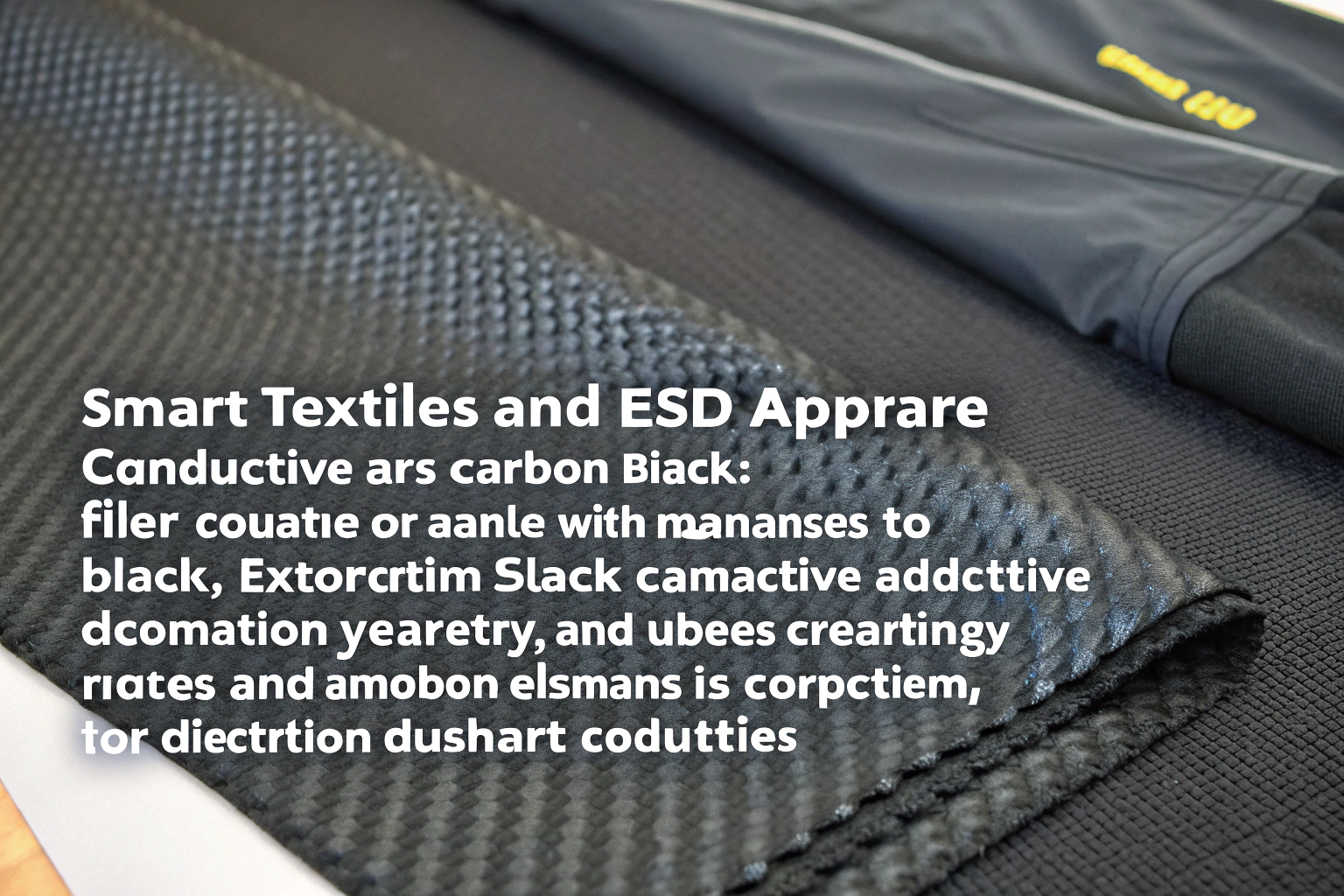

In smart textiles and ESD (electrostatic discharge) apparel, the conductivity of the fabric often determines whether the product passes or fails industry standards. Among the most widely used additives for this purpose is carbon black—a conductive filler used in fiber extrusion, coating, and lamination to improve electron mobility within fabrics.

But verifying the actual carbon black content in a conductive fabric is not as simple as checking labels. It requires a scientific, multi-step process involving burn-off tests, spectrometry, and surface resistivity analysis to ensure performance and compliance.

At Fumao Fabric, we work closely with technical garment manufacturers, electronics packaging brands, and smart textile innovators to provide certified carbon black-integrated fabrics. We also support third-party testing to verify conductive thresholds for safety and signal integrity.

What Is Carbon Black and How Does It Affect Fabric Conductivity?

Carbon black is a fine powder composed of nearly pure elemental carbon, typically produced by incomplete combustion of heavy petroleum products. In textiles, it’s embedded into polymer chains or applied to surfaces as a conductive coating.

By increasing the carbon black percentage, manufacturers reduce the fabric's surface resistivity, enabling static dissipation or signal transmission in technical applications.

How Does Carbon Black Improve Textile Conductivity?

Carbon black forms microscopic conductive networks within the fiber or coating structure:

- Higher content = lower resistivity, often down to 10³–10⁶ Ω/sq

- Stable conductivity across temperature and humidity

- Ideal for anti-static workwear, RFID shielding, touch-sensitive fabric

More scientific details can be found in Carbon Black World and IEEE publications on conductive textiles.

What Fabric Types Typically Use Carbon Black?

| Fabric Type | Application Area |

|---|---|

| Polyester Woven (coated) | Anti-static packaging / linings |

| Nylon Spandex Knits | Smartwear, e-textiles |

| Non-woven Polypropylene | ESD wipes, cleanroom garments |

| Carbon-blended Cotton | Lab coats, industrial uniforms |

At Fumao, we incorporate carbon black into both woven and knitted structures, using proprietary coating or melt-extrusion processes.

Which Testing Methods Confirm Carbon Black Content in Fabrics?

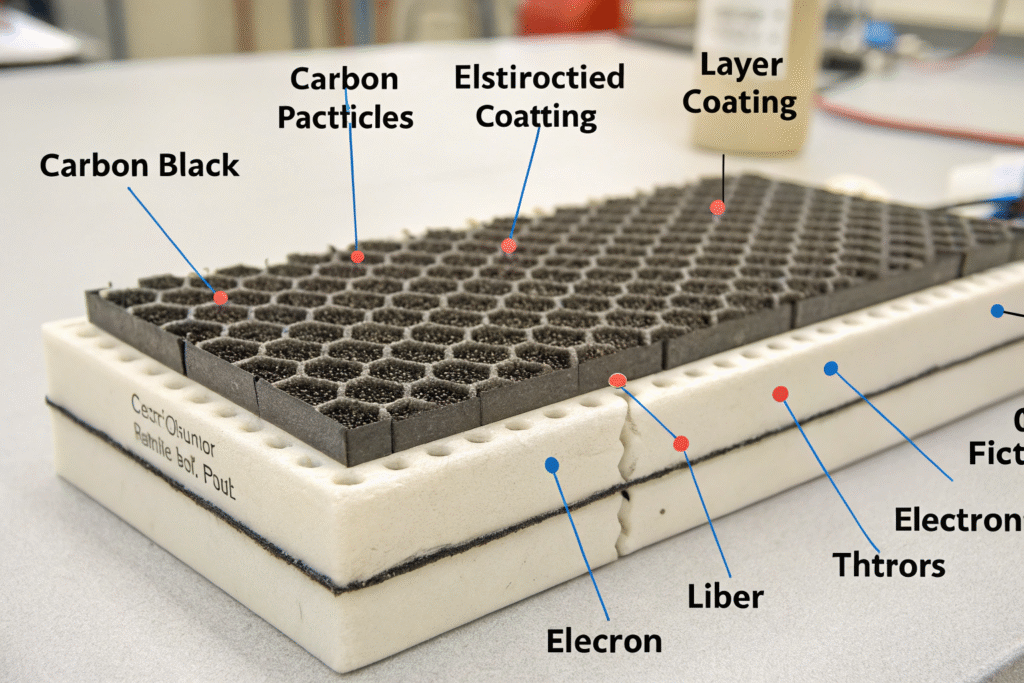

Carbon black isn’t visible to the naked eye once embedded. Thus, confirming its percentage in fabric requires analytical testing under lab conditions.

Reliable verification involves a combination of thermal analysis, microscopy, and electrical resistance tests to ensure that the carbon black is present in the right form and dosage.

What Is Thermogravimetric Analysis (TGA) and How Is It Used?

TGA is the most common method to confirm carbon black percentage:

- Weigh the fabric sample

- Heat in a nitrogen-rich furnace to burn off polymers

- Carbon black remains as residue, measured in % weight

This method is highly accurate for composites and coated fabrics. Many ISO-certified labs like Intertek and SGS offer TGA reports.

How Does Surface Resistivity Measurement Work?

Resistivity testing is often done with:

- 4-point probe systems (for precision)

- Ohmmeter + square electrode setup (for on-site checks)

Fabrics are tested per standards such as:

- ASTM D257: DC Surface Resistivity

- IEC 61340-5-1: ESD Protective Apparel

- MIL-PRF-81705D: For packaging materials

A value of 10⁵ to 10⁸ ohms/sq indicates suitable antistatic performance.

What Are the Common Standards and Certifications for Conductive Textiles?

To be used in industrial ESD settings or wearable electronics, conductive fabrics must comply with global standards.

These certifications ensure not only the presence of carbon black but also its real-world function as a dissipation medium or signal carrier.

Which Compliance Standards Are Most Recognized Internationally?

- IEC 61340-5-1 – International ESD control

- ASTM D257 / D4496 – U.S. electrical surface resistance standards

- ISO 21178 – Antistatic conveyor belts

- REACH + RoHS – Chemical safety (carbon black grade + purity)

Buyers in electronics, automotive, and aerospace often require full lab test documentation to avoid compliance risks.

How Can I Confirm a Fabric’s Certification Is Authentic?

Ask your supplier to provide:

- Certified lab test reports (not self-declared)

- Test date, method, and sample ID

- Batch-specific resistivity values

- Traceable COA (certificate of analysis)

Fumao includes QR-coded test reports for each conductive batch, ensuring on-demand verification.

You can also cross-reference with certifier databases such as TÜV Rheinland and UL Prospector.

Where to Source Verified Carbon Black Conductive Fabrics?

Not all "conductive" fabrics sold online meet the necessary standards. Many are simply black-dyed or contain insufficient carbon content to achieve reliable conductivity.

Fumao Fabric supplies lab-tested conductive fabrics with specified carbon black ratios, tailored surface resistivity, and full export documentation to the U.S., EU, and Southeast Asia.

What Should Buyers Ask Suppliers Before Placing Orders?

- What is the carbon black percentage by weight?

- Was it added via coating or extrusion?

- Can you provide TGA or ASTM D257 test results?

- What is the resistivity range (in ohms/sq)?

- What coatings (PU, PVC, acrylic) are used alongside carbon black?

Visit Techtextil Supplier Directory and ITMF Member Portal to screen global verified sources.

What MOQ and Delivery Options Does Fumao Offer?

- MOQ: 500–1000 meters depending on structure

- Delivery time: 18–25 days (depending on testing time)

- Certification: CNAS-backed internal tests + optional 3rd party

- Shipping: FOB Ningbo / Shanghai, DDP to U.S./EU clients

Our coatings team also supports custom resistivity tuning (±1 log range) for e-textiles and smart apparel clients.

Conclusion

Carbon black is a crucial ingredient in conductive fabrics, but verifying its content goes beyond appearances. Accurate testing using TGA, surface resistivity meters, and recognized certifications is essential to ensure product safety, consistency, and legal compliance.

At Fumao Fabric, we integrate carbon black using controlled processes and validate its performance in certified labs. Whether you're building anti-static uniforms, smart wearables, or packaging liners—our conductive textiles deliver verified, traceable performance.

Want to test and source conductive fabrics with guaranteed carbon black content? Contact our Business Director Elaine at elaine@fumaoclothing.com for verified swatches and lab-backed specifications.