In the era of climate urgency and rising consumer demand for sustainability, zero-waste manufacturing is no longer optional—it’s a strategic imperative. For textile brands, choosing the right fiber isn't just about softness or breathability; it's about minimizing environmental damage from start to finish. That’s where Lyocell and its closed-loop production system come in.

Lyocell, made from sustainably harvested wood pulp and processed in a closed-loop system, is one of the most eco-responsible fibers in modern fashion. Its production recycles up to 99.7% of its non-toxic solvent and generates minimal waste. This circularity offers a real path toward zero-waste apparel manufacturing.

At Fumao Fabric, we supply GRS- and Lenzing-certified Lyocell fabrics that support full traceability and closed-loop compliance. Whether you're developing eco loungewear, performance shirts, or premium blends—our Lyocell options allow you to combine sustainability with performance and softness.

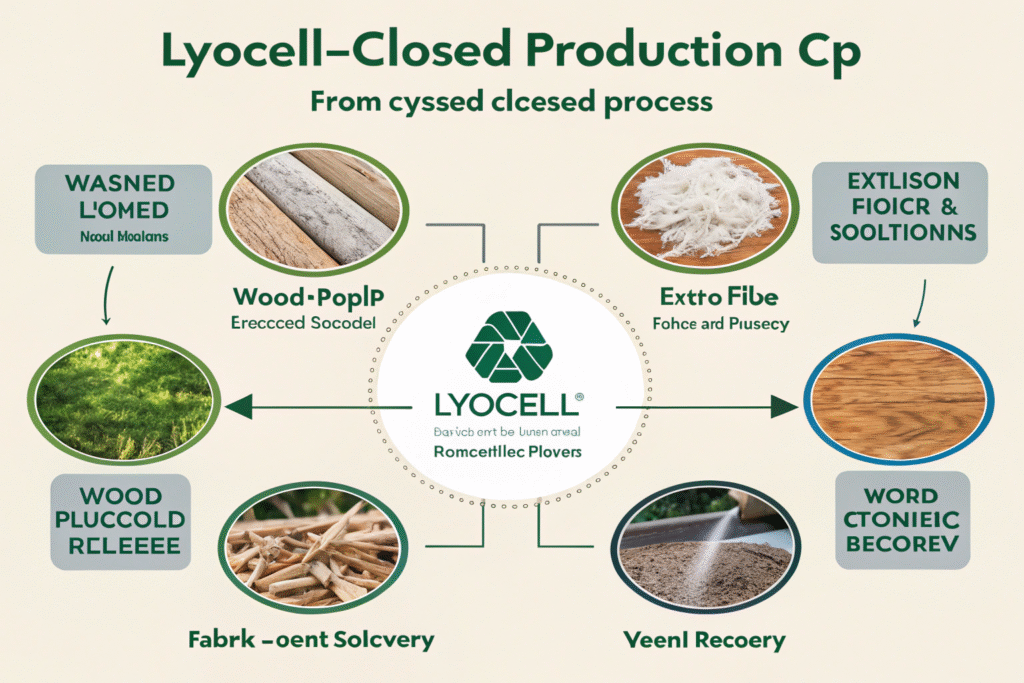

What Is Closed-Loop Lyocell Production and How Does It Work?

Lyocell is a cellulosic fiber made primarily from eucalyptus, beech, or birch wood. What sets it apart is not just the fiber—but how it’s made.

Closed-loop Lyocell production uses NMMO (N-Methylmorpholine N-oxide), a non-toxic solvent that dissolves pulp into a slurry. This solvent is almost entirely recovered and reused in the same cycle, drastically reducing water usage, emissions, and toxic runoff.

Why Is the Solvent Recovery Process So Critical?

The closed-loop model prevents harmful solvents from entering local ecosystems.

- 99.7% of the solvent is recycled, minimizing chemical waste

- No bleach is used, unlike conventional viscose production

- Lower energy and water footprint compared to cotton or polyester

More details can be found on Lenzing’s Lyocell technology and Canopy’s Hot Button Report, which ranks producers on forest-safe and circular practices.

How Is Lyocell Different from Modal or Viscose?

| Feature | Lyocell | Modal | Viscose |

|---|---|---|---|

| Solvent | NMMO (recyclable) | NaOH (non-recycled) | CS2 + NaOH (toxic) |

| Process | Closed-loop | Semi-closed | Linear / Polluting |

| Environmental Impact | Low | Moderate | High |

Lyocell is the only mainstream cellulosic fiber currently considered "closed-loop" by ZDHC and Greenpeace standards.

What Are the Environmental Benefits of Closed-Loop Lyocell?

Choosing closed-loop Lyocell isn’t just a trend—it’s a measurable improvement in environmental performance.

Lyocell production cuts water consumption by up to 80% compared to cotton and eliminates the toxic byproducts typical in rayon or viscose production. It also lowers CO₂ emissions per kilogram of fiber output.

How Much Water and Energy Does Lyocell Save?

Based on LCA data:

- Cotton: ~10,000 liters of water/kg fiber

- Polyester: ~125 MJ/kg energy

- Lyocell: ~2500 liters water/kg + ~50 MJ/kg energy

Visit Textile Exchange’s Preferred Fiber Matrix and Higg MSI for fiber impact data.

Is Lyocell Biodegradable and Safe for Composting?

Yes. Lyocell is:

- Fully biodegradable in soil and marine environments (unlike polyester)

- Compostable within 4–8 weeks under industrial conditions

- OEKO-TEX® Standard 100 and FSC®-certified when sourced responsibly

This makes it ideal for sustainable fashion brands pursuing circular design strategies.

Which Products Are Ideal for Closed-Loop Lyocell Fabric?

Lyocell is a high-performance fiber with luxurious softness, high breathability, and moisture regulation—making it perfect for a wide range of garments.

From everyday basics to technical blends, Lyocell fabrics work well across sectors including intimates, activewear, luxury menswear, and eco-home textiles.

Why Do Athleisure and Underwear Brands Prefer Lyocell?

Top performance features:

- Moisture-wicking + breathability rivaling synthetics

- Natural antibacterial properties

- Smooth fiber surface = hypoallergenic and soft for sensitive skin

Popular brands like Allbirds and Boody have integrated Lyocell into their base layers and t-shirts for its performance and low-impact credentials.

Can Lyocell Be Blended with Other Eco-Fibers?

Absolutely. Fumao’s Lyocell product range includes:

| Blend Type | Target Application |

|---|---|

| Lyocell + Organic Cotton | Shirts, dresses |

| Lyocell + Spandex | Yoga pants, base layers |

| Lyocell + Hemp | Structured workwear |

| Lyocell + Recycled Poly | Stretch denim, jackets |

Blending allows brands to customize drape, elasticity, and cost structure while preserving sustainability.

What Should Buyers Look For When Sourcing Lyocell Fabrics?

Not all Lyocell is created equal. “Closed-loop” isn’t just a buzzword—it must be backed by production transparency and recognized standards.

Buyers should validate the entire fiber journey: certified forest sources, non-toxic chemistry, solvent recycling rates, and emissions transparency.

Which Certifications Indicate Closed-Loop Lyocell?

Look for:

- Lenzing™ TENCEL™ Certification

- FSC® or PEFC® Wood Source Label

- OEKO-TEX® and GRS compliance

- ZDHC MRSL Approval for solvent and chemical inputs

More info available at Lenzing E-Branding Hub and GRS Textile Certification.

How Can Fumao Help Buyers Source Closed-Loop Lyocell?

We provide:

- Fully traceable Lenzing-certified yarn sources

- Fabric finishes including anti-odor, wrinkle-resistant, or brushed

- MOQ flexibility (starting at 300m)

- Real-time testing data via QR-coded tracking (shrinkage, colorfastness, pH)

Our team also supports customized blend development and fast lab dips for seasonal launches.

Conclusion

Closed-loop Lyocell production represents a rare convergence of performance, softness, and genuine sustainability. It eliminates the harmful byproducts of conventional viscose, dramatically reduces water and chemical waste, and supports a zero-waste textile future.

At Fumao Fabric, we’re proud to be part of this circular movement—offering responsibly sourced, tested, and traceable Lyocell fabrics to global fashion and home brands.

Want to co-create sustainable products with zero-waste Lyocell? Contact our Business Director Elaine at elaine@fumaoclothing.com to request certified Lyocell swatches and start your sourcing journey today.