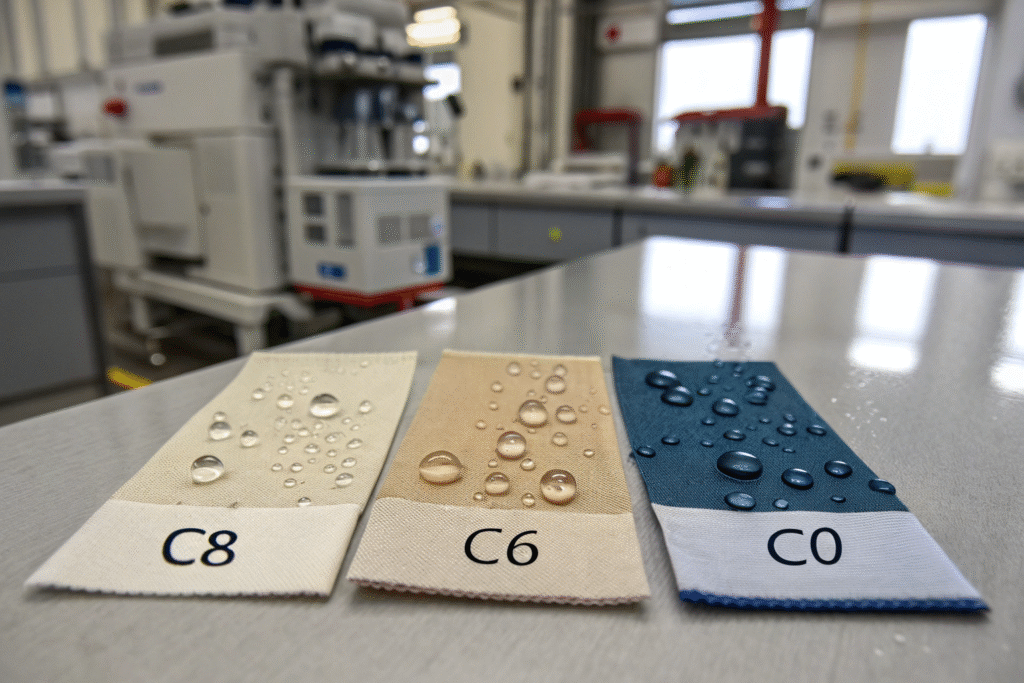

Outdoor apparel has long relied on Durable Water Repellent (DWR) finishes to protect wearers from rain and snow. However, traditional DWR treatments—especially those using long-chain perfluorinated compounds (PFCs)—have come under scrutiny for their environmental persistence and toxicity. Consumers are demanding performance without pollution, and global retailers are now phasing out harmful C8 and even C6 fluorocarbons.

The industry’s answer? C0 PFC-free DWRs—next-generation water-repellent treatments based on silicones, dendrimers, and plant-based chemistries. These new technologies provide water resistance while complying with REACH, ZDHC, and Greenpeace Detox requirements.

At Fumao Fabric, we’ve partnered with advanced chemical innovators to apply the latest C0 finishes to our technical outerwear textiles. Whether for hiking jackets, ski apparel, or windbreakers, our fabrics deliver sustainability with real-world rain protection—without toxic trade-offs.

What Are C0 DWR Finishes and Why Are They Fluorine-Free?

Traditional DWR coatings use fluoropolymers that contain fluorine atoms, which resist water, oil, and stains. But these molecules, especially long-chain C8s, persist in the environment and accumulate in human tissue.

C0 DWRs eliminate fluorine altogether. They use alternative chemistries like silicone emulsions, polyurethane dispersions, and hyperbranched polymers to repel water without toxic residues.

Why Are Brands Phasing Out C6 and C8 DWRs?

Due to regulatory pressure and environmental activism, brands are removing all perfluorinated chemicals. Key drivers include:

- REACH and California Prop 65 bans on PFAS

- Greenpeace Detox Campaign, targeting hazardous PFCs

- Global retailer commitments (e.g., H&M, Patagonia, The North Face)

Learn more about PFAS phaseout at ChemSec Marketplace and OEKO-TEX® Eco Passport.

What Chemicals Are Used in Modern C0 DWR Formulas?

Typical non-fluorinated agents include:

| Base Chemistry | Key Brands / Traits |

|---|---|

| Silicone Emulsion | HeiQ Eco Dry, breathable, soft |

| Hyperbranched Polymer | Beyond Surface Technologies (BST) |

| Polyurethane Dispersion | Rudolf Bionic-Finish Eco |

| Fatty-Acid Based | Teflon EcoElite, bio-based |

These ingredients offer rain resistance with lower runoff impact and recyclability.

How Effective Are C0 DWRs Compared to Fluorinated Versions?

The major challenge for C0 DWRs is maintaining performance without the oil-repellent capabilities of fluorocarbons.

While C0 finishes can match fluorinated DWRs for water repellency, they are weaker in oil and stain resistance, making them better suited to outerwear than workwear or culinary uniforms.

Can C0 DWR Coatings Match Rain-Repellency Standards?

Yes—especially for moderate outdoor use. Tests show C0 DWRs achieve:

- ISO 4920 Spray Test Ratings of 80–100 (very good)

- AATCC 22 Water Repellency scores of 90+ (beading maintained after 10 washes)

View comparative test data at Rudolf Group and HeiQ Performance Index.

How Durable Are PFC-Free DWR Finishes After Washing?

Durability depends on the application process, curing temperature, and fiber content. Fumao’s latest laminated polyester shells with C0 finish retain 80% repellency after 20 home washes.

Tips for improving C0 DWR life:

- Use high-cure processing (140°C+)

- Combine with PU membranes

- Recommend tumble drying or heat-reactivation for end customers

What Outerwear Fabrics Work Best with C0 DWR Coatings?

Not all fabrics bond equally with non-fluorinated DWRs. Certain weaves and yarn types show better water repellency after C0 treatment.

C0 DWRs perform best on synthetics like polyester and nylon, particularly when tightly woven or laminated. Natural fibers require extra binder layers to match performance.

Which Fabrics Perform Best with C0 Water-Repellency?

Our lab has tested dozens of combinations. Here are top performers:

| Fabric Type | C0 DWR Outcome |

|---|---|

| 100% Nylon Taslan | Excellent |

| Recycled Polyester Pongee | Very Good |

| Nylon-Spandex Softshell | Excellent |

| Cotton Twill | Moderate (needs binder) |

Get insights on fabric compatibility from Textile Exchange’s Preferred Fiber Guide and ZDHC Chemical Gateway.

Can C0 DWRs Be Applied to Eco-Fabrics Like Tencel or Hemp?

Yes, but with caveats. Cellulose fibers absorb water, so repellency is surface-limited. We’ve seen positive results with:

- Tencel™ + PU-coated backer

- Blended hemp with tight twill weave

Our best-selling eco-DWR styles combine recycled PET face + bio-based film + silicone DWR.

What Should Buyers Know When Sourcing PFC-Free DWR Outerwear Fabrics?

PFC-free sourcing isn’t just a chemical choice—it’s a compliance strategy. Buyers need to validate certifications, wash durability, and chemical inputs across the chain.

C0 DWR doesn’t mean “green” by default. You need suppliers with transparent MSDS, tested performance, and sustainable curing processes.

Which Certifications Prove a Fabric Is PFC-Free?

Look for:

- ZDHC Level 3 Approved Chemistry

- OEKO-TEX® Standard 100 + Eco Passport

- bluesign® approved formulations

- REACH Annex XVII compliance

Also ask for test reports from Intertek, SGS, or third-party labs with ISO 4920 data.

What Key Questions Should You Ask Suppliers?

- What base chemistry is your C0 finish (silicone, PU, dendrimer)?

- How many wash cycles does it retain 80% repellency?

- Is it certified by ZDHC or bluesign?

- Can you provide MSDS and Eco Passport documentation?

At Fumao, we provide these with each eco-DWR order, backed by CNAS lab verification.

Conclusion

As the outdoor industry transitions away from harmful PFCs, C0 DWR finishes are becoming the new performance standard. They offer real water repellency with none of the toxic baggage—benefiting both consumers and the planet.

At Fumao Fabric, we offer a wide portfolio of PFC-free outerwear materials tested to ISO and AATCC standards. Our sustainable finishes, combined with durable laminates and functional coatings, help brands stay compliant and competitive.

Ready to upgrade your outerwear line with C0 DWR-treated fabrics? Contact our Business Director Elaine at elaine@fumaoclothing.com to start sourcing today.

565 Responses

El manual que psicólogos usan como base para tratar dependencia emocional https://lasmujeresqueamandemasiadopdf.cyou/ pedir prestado las mujeres que aman demasiado pdf

Experience the rush of space exploration without the risk. The Project Hail Mary PDF is the safe way to travel. This ebook is perfect for armchair astronauts. Download it today and explore the galaxy. https://projecthailmarypdf.top/ project hail mary pdf online free

Dragons are the ultimate weapon in this war for survival. The Fourth Wing PDF is your handbook to understanding them. Download the book today and become an expert on the Empyrean lore. https://fourthwingpdf.top/ Fourth Wing Series

Why wait for shipping? Get the A Court of Mist and Fury PDF instantly. This digital format is the fastest way to start reading. Download the file now and satisfy your need for fantasy romance. https://acourtofmistandfurypdf.top/ Which Book Comes After A Court Of Mist And Fury

Descubre cómo la serenidad es contagiosa, baja el manual y aprende a calmar a las fieras, mandando a la media la histeria colectiva de forma educada y convirtiéndote en un faro de luz en la tormenta. https://comomandaralamediadeformaeducadapdf.cyou/ Como Mandar A La Mierda De Forma Educada Comprar

We offer the most reliable connection to the Lights Out PDF you will find online. Our links are constantly monitored to ensure up-time and availability. Join a community of readers who know where to find the best digital resources. https://lightsoutpdf.top/ Where To Watch Lights Out

Fantasy firestorm Iron Flame PDF! Rebecca Yarros wins. Free at ironflamepdf.top! https://ironflamepdf.top/ Who Is Ciaran In Iron Flame

Sunrise on the Reaping offers Suzanne Collins’ powerful exploration of trauma and resilience in dystopian Panem. This PDF prequel follows sixteen-year-old Haymitch during the fiftieth Hunger Games. Understand his broken spirit before mentoring Katniss. Download free instantly without registration today. https://sunriseonthereapingpdf.top/ Hunger Games Sunrise On The Reaping

Read the In Your Dreams PDF and be transported. It is a magical experience to have a whole world inside your device, waiting for you to unlock it. https://inyourdreamspdf.top/ In Your Dreams Novel English

Building a personal library of digital books is a hobby for many of us. If you focus on fiction, an archive of romance novels is an indispensable resource. Being able to download a PDF allows for offline reading, which is perfect for those times when you do not have internet access. https://anarchiveofromancepdf.top/ An Archive Of Romance Novel Download

This thriller makes you scream, and you can grab the PDF. It is a pulse-pounding read. The digital edition allows for night mode reading. suspenseful and scary, it is perfect for reading under the covers. https://youcanscreampdf.top/ You Can Scream Full Book Pdf

The cost of books can add up quickly for a fast reader. A free or low-cost archive of romance is a financial lifesaver. I can read as much as I want by downloading PDF files, keeping my entertainment budget in check while satisfying my craving for stories. https://anarchiveofromancepdf.top/ An Archive Of Romance Pdf File

Experience the rush of a page-turner with the digital version. The PDF of It Should Have Been You is fast-paced. It should have been you racing to the end. Get the file now and enjoy. https://itshouldhavebeenyoupdf.top/ It Should Have Been You Online Reader

Discover the legacy of Alcott Hall with this detailed PDF. The document is filled with historical facts and figures. Download your copy today and enjoy the convenience of having this comprehensive resource available on your computer or tablet. https://alcotthallpdf.top/ Alcott Hall Pdf Reddit

You can find a legend that makes you scream. This PDF is old. It is a history. The digital format is new. modern and retro. https://youcanscreampdf.top/ You Can Scream Rebecca Zanetti Download

If you are a writer, reading widely is essential. An archive of romance is a textbook for understanding plot structure and character development. I analyze the PDF novels I download to see how successful authors build tension and resolve conflicts in their stories. https://anarchiveofromancepdf.top/ An Archive Of Romance Pdf Download

Join the community of readers who love this book by getting the digital version. The PDF of It Should Have Been You is easy to navigate. It should have been you sharing your thoughts on this story. Download the file today and get involved. https://itshouldhavebeenyoupdf.top/ It Should Have Been You Scanned Copy

The Alcott Hall PDF is available for immediate download. This file is a treasure trove of historical information. Secure your copy now to get the full story of the estate, presented in a clean and easy-to-read digital format. https://alcotthallpdf.top/ Alcott Hall Pdf Free Link

This mystery will make you scream, and you can solve it with the PDF. It is a complex puzzle. The digital file allows you to flip back and forth easily. engaging and interactive. https://youcanscreampdf.top/ You Can Scream Ios Epub

Unearth the hidden layers of a dramatic relationship. This book is perfect for a long flight or a quiet evening. Finding the PDF is easy and quick. Start reading today to see how the story of a wife and her rival plays out. https://myhusbandswifepdf.top/ My Husband’s Wife Review Pdf

I find that reading romance helps reduce stress. A calming story from an archive of romance is my escape from anxiety. I keep a few “comfort reads” in PDF format on my phone so I have immediate access to a soothing story whenever I feel overwhelmed. https://anarchiveofromancepdf.top/ Ava Reid Archive Of Romance Pdf

Get the full Anatomy of an Alibi PDF. This download is quick. enjoy the suspense. https://anatomyofanalibipdf.top/ Read Anatomy Of An Alibi Online Free

I enjoy the simplicity of a text-based interface. A minimalist archive of romance focuses on the books, not the graphics. I can quickly find the text I want and download the PDF without being distracted by unnecessary ads or slow-loading images. https://anarchiveofromancepdf.top/ An Archive Of Romance Deluxe Illustrated Edition Pdf

Looking for a fresh and exciting story to read on your device? The Love in Plane Sight PDF is a top choice for romance addicts. This book delivers on its promise of sweet moments and dramatic turns. Access the digital file today and treat yourself to a great read. https://loveinplanesightpdf.site/ Love In Plane Sight Sequel

Let the Graceless Heart PDF be your guide. It is a map to emotion. It leads you through a story of a graceless journey, arriving at a destination of heart-felt love and redemption. https://gracelessheartpdf.site/ Graceless Heart Historical Fantasy

Discover a world of romance at your fingertips. The Boyfriend Candidate PDF is ready for you. It is accessible and convenient. Access the digital edition today and start your journey into this wonderful book. https://theboyfriendcandidatepdf.site/ The Boyfriend Candidate Printable Pdf

perplexity price https://uniqueartworks.ru/perplexity-kupit.html

нейросеть perplexity https://uniqueartworks.ru/perplexity-kupit.html

Read the book that challenges the “bury your gays” trope head-on. It is a survival horror story with a meta-fictional twist. Accessing the Bury Your Gays PDF allows you to easily search and reference your favorite passages in this densely layered narrative. https://buryyourgayschucktinglepdf.site/ Bury Your Gays Pdf File

Break the cycle of restriction and bingeing with this metabolic guide. It promotes a healthy relationship with food. The metabolic freedom pdf helps you understand your body’s signals and needs, leading to natural weight loss and metabolic freedom. https://metabolicfreedom.top/ Metabolic Freedom Book Pdf

El respeto es la base, si falta, vete. Este libro te da la fuerza. Consigue el archivo y reafirma tus valores. No aceptes menos de lo que das y mereces en una relación. https://lasmujeresqueamandemasiadopdf.cyou/ Las Mujeres Que Aman Demasiado Book Cover

Si buscas autenticidad, la teoría de Let Them es el camino. Lee la guía en español y busca el PDF completo. Ser auténtico requiere valentía para dejar que otros te juzguen sin que te importe; esta teoría te da el coraje para ser tú mismo sin disculpas. https://lateorialetthem.top/ Libro La Teoria Let Them Pdf Gratis

Gain control over your weight by balancing your hormones. This resource is full of tips. The metabolic freedom pdf teaches you how to create an internal environment that favors fat burning and discourages fat storage. https://metabolicfreedom.top/ Metabolic Freedom Weight Loss

No busques afuera lo que debes encontrar dentro de ti. Este libro electrónico te enseña a cultivar el amor propio. Es un texto indispensable para cualquier persona que quiera mejorar su vida sentimental. Descárgalo y empieza tu transformación personal ahora. https://lasmujeresqueamandemasiadopdf.cyou/ Libro Las Mujeres Que Aman Demasiado Opiniones

La teoría de Let Them promueve la autonomía emocional. Busca la lectura en español y asegúrate de tener el texto completo. Es una herramienta poderosa para dejar de depender de la aprobación ajena y comenzar a validar tus propias emociones y decisiones sin miedo al rechazo. https://lateorialetthem.top/ Mentalidad De Abundancia Y Desapego

Si alguna vez te has preguntado cuál es la forma educada de terminar una conversación desagradable, este archivo tiene las respuestas, descarga la guía completa y conviértete en un experto en asertividad y buenos modales ante situaciones de estrés social. https://comomandaralamediadeformaeducadapdf.cyou/ Como Mandar A La Mierda De Forma Educada En Pdf

Entender la dinámica del desapego es fácil con la teoría de Let Them. Accede a la traducción en español y descarga el conocimiento completo. Al dejar que los demás actúen según su voluntad, te liberas de la responsabilidad de sus decisiones y encuentras un espacio de serenidad que antes no conocías. https://lateorialetthem.top/ Vivir Sin Controlar A Los Demás

Si sientes vacío cuando no estás en pareja, este texto es para ti. Descarga el archivo y llena ese vacío con comprensión y autoestima. Es una obra que ha transformado vidas y puede transformar la tuya si le das una oportunidad. https://lasmujeresqueamandemasiadopdf.cyou/ Mujeres Que Aman Demasiado Pdf Gratis

Iron Flame PDF: Blaze your way through fantasy! Violet faces dragons, dangers, desires. Perfect sequel. Free access at ironflamepdf.top – download now! https://ironflamepdf.top/ Iron Flame Map

Witness transformations both physical and emotional as our heroine accepts her true calling. https://heiroffirepdf.top/ What Chapter Does Sorscha Die In Heir Of Fire

Sunrise on the Reaping offers Suzanne Collins’ most emotional narrative yet in the Hunger Games universe through Haymitch’s tragic journey during the Quarter Quell. This PDF prequel follows his impossible choices. Discover what made him drink before mentoring Katniss. Download free instantly without any registration today. https://sunriseonthereapingpdf.top/ Sunrise On The Reaping Movie Release Date

We offer the most reliable connection to the Lights Out PDF you will find online. Our links are constantly monitored to ensure up-time and availability. Join a community of readers who know where to find the best digital resources. https://lightsoutpdf.top/ Lisa Marie Presley Lights Out

Purple prose no, wait – Iron Flame pure! Violet pure power. Free at ironflamepdf.top! https://ironflamepdf.top/ Iron Flame Pdf Free Download

Experience magical combat described with clarity and visceral impact. https://heiroffirepdf.top/ What Happens At The End Of Heir Of Fire

We provide the Lights Out PDF with a focus on clear typography. The fonts are embedded to ensure it looks right on any system. consistency and quality are guaranteed. https://lightsoutpdf.top/ Lights Out Pdf Online Free

Download Sunrise on the Reaping PDF free right now. Suzanne Collins crafts this fifth Hunger Games novel exploring Haymitch Abernathy’s fateful day during the Quarter Quell. Witness the events that shaped him forever. Get instant access without any registration or payment requirements today. https://sunriseonthereapingpdf.top/ Sunrise On The Reaping Book

Start your reading adventure with the Lights Out PDF from our trusted site. We provide a smooth, error-free download process for every user. Join thousands of others who have found their documents here. https://lightsoutpdf.top/ Where To Watch Lights Out

Ignite your world with Iron Flame PDF! Fantasy fuels Violet’s flight. Free at ironflamepdf.top today! https://ironflamepdf.top/ Iron Flame Pdf

Sunrise on the Reaping delivers Suzanne Collins’ most emotional Hunger Games story yet. This PDF prequel reveals Haymitch’s heartbreaking past before Katniss changed everything. Witness the fiftieth Games’ brutality. Download your free copy instantly with no signup barriers at all. https://sunriseonthereapingpdf.top/ Sunrise On The Reaping Movie Release Date

Uncover the personal cost of wielding power meant to protect others. https://heiroffirepdf.top/ Heir Of Fire Pdf Free Download English

Read the in-depth study that challenges conventional wisdom. This fake skating pdf offers fresh perspectives on athletic integrity, encouraging readers to think critically about what constitutes a valid performance in a competitive setting. https://fakeskatingpdf.site/ Fake Skating Lynn Painter Zlibrary

The Charlie Method PDF is a precision instrument. It allows for fine-tuning of your life. This guide is delicate yet powerful. Download it now to make the micro-adjustments that lead to macro-results in your overall performance. https://thecharliemethodpdf.site/ The Charlie Method Book Club

Revisit the Shield of Sparrows whenever you like with a PDF stored on your phone. It is perfect for killing time in waiting rooms or on public transport. Turn idle moments into exciting adventures with this portable digital document. https://shieldofsparrowspdf.site/ Shield Of Sparrows Ebook

Find out how to identify the subtle signs of fatigue and overtraining. This fake skating pdf is an essential guide for parents and coaches who want to ensure the long-term health and success of their athletes. https://fakeskatingpdf.site/ Fake Skating Lynn Painter Free Ebook

Develop your potential with the Charlie Method. This PDF guide nurtures your hidden talents. It is a greenhouse for growth. Read it today to provide the right conditions for your abilities to bloom and flourish. https://thecharliemethodpdf.site/ The Charlie Method Full Book Pdf

Immerse yourself in the competitive spirit of the characters. The Check and Mate PDF is the motivational tool, offering a story that inspires you to pursue your own passions and goals. https://checkandmatepdf.site/ Books Like Check And Mate

Explore the nuances of a relationship built on competition and mutual respect. The Check and Mate PDF edition preserves the formatting and style of the original print, giving digital readers the authentic experience they deserve while enjoying the convenience of an ebook. https://checkandmatepdf.site/ Chess Puzzles For Kids Pdf

Maximize your output with the Charlie Method PDF. This guide turns effort into gold. It is an alchemy of productivity. Download the file today to get the most out of every hour you invest in your work. https://thecharliemethodpdf.site/ The Charlie Method Epub

The Shield of Sparrows PDF is a laptop luxury. It turns work time into reading time. It is a secret pleasure. https://shieldofsparrowspdf.site/ Who Is The Love Interest In Shield Of Sparrows

Explore the global perspective on this issue with our international report. The fake skating pdf compares how different federations and countries approach the problem, offering a diverse look at the regulatory landscape of the sport. https://fakeskatingpdf.site/ Fake Skating Lynn Painter Writing Style

Explore the infinite possibilities of the mind. The Great Big Beautiful Life PDF is a great universe. It contains big stars of a beautiful life. This digital file is a journey into the vastness of human potential. https://greatbigbeautifullifepdf.site/ “Great Big Beautiful Life” Pdf

Redécouvrez les valeurs humanistes portées par ce récit mythique. Le numérique est un vecteur puissant pour ces valeurs. Avec Le Petit Prince en PDF, vous avez entre les mains un manifeste de douceur et d’intelligence, à lire et à faire lire autour de vous. https://lepetitprincepdf.site/ Le Petit Prince Pdf Gratuit Pour Tous

Ce livre vous fera passer par toutes les émotions, de la peur à la surprise totale. La version numérique est à votre portée pour une lecture inoubliable. Laissez-vous guider par cette femme de ménage dans les couloirs sombres d’une maison qui cache bien son jeu et ses cadavres. https://lafemmedemenagepdf.site/ Comment Se Termine La Femme De Menage

Iphone 17 Air Size Dimensions Apple Iphone 17 Event September 2025 Date How Much Storage Does The Iphone 17 Pro Max Have? Iphone 17 Air Size Screen Apple Iphone 17 Pro Reviews Iphone 17 Air Release Date Price Iphone 17 Release Date Apple Iphone 17 Coming Out

Découvrez le destin de personnages attachants avec ce livre en format dématérialisé. Téléchargez ce PDF et préparez-vous à une lecture qui vous prendra aux tripes. Une œuvre marquante qui résonnera en vous longtemps, à lire absolument cette année. https://atoutjamaispdf.site/ Film A Tout Jamais

Un voyage interplanétaire sans quitter votre fauteuil, c’est la promesse de ce livre. La version électronique rend ce voyage encore plus accessible. Téléchargez Le Petit Prince en PDF et laissez-vous guider par la voix intérieure de l’auteur qui résonne à travers chaque phrase de ce récit magistral. https://lepetitprincepdf.site/ Le Petit Prince Pdf Tablette

Ce livre vous fera passer par toutes les émotions, de la peur à la surprise totale. La version numérique est à votre portée pour une lecture inoubliable. Laissez-vous guider par cette femme de ménage dans les couloirs sombres d’une maison qui cache bien son jeu et ses cadavres. https://lafemmedemenagepdf.site/ Site Pour Télécharger La Femme De Ménage

Experience the beauty of a grateful heart. The Great Big Beautiful Life PDF is a great song. It sings big praises for a beautiful life. This text fills your heart with thanksgiving. https://greatbigbeautifullifepdf.site/ Great Big Beautiful Life Free Download

Saisissez la chance de lire ce roman culte en format numérique pratique. Tout le bleu du ciel est une histoire qui résonne en chacun de nous, et cette version téléchargeable vous permet de la découvrir sans attendre, avec une qualité de texte parfaite pour tous les écrans. https://toutlebleuducielpdf.site/ Tout Le Bleu Du Ciel Mon Poche

Ce téléchargement vous ouvre les portes d’un monde fascinant. Le livre est une exploration riche et nuancée de l’enfance. Plongez dans ce récit où chaque mot est choisi pour émouvoir, créant une connexion intime entre l’auteure et son lecteur. https://lecoeurarireetapleurerpdf.site/ Le Cœur À Rire Et À Pleurer Genre Littéraire

Rejoignez les nombreux lecteurs qui ont été bouleversés par le destin d’Émile en vous procurant ce fichier de lecture numérique. C’est le moment idéal pour lire tout le bleu du ciel et comprendre la force des liens qui se tissent sur la route, le tout accessible en quelques clics seulement. https://toutlebleuducielpdf.site/ Site Pour Télécharger Tout Le Bleu Du Ciel

Pour une approche critique ou simplement pour le plaisir des mots, ce roman est une ressource inépuisable de réflexions sur l’amour et la liberté. Le fichier Bonjour Tristesse PDF vous donne les clés de cette œuvre magistrale, vous permettant de la lire et de la relire à volonté sur vos écrans. https://bonjourtristessepdf.site/ Bonjour Tristesse Pdf Roman

La fin tragique de Julien Sorel est l’une des scènes les plus poignantes de la littérature. Elle conclut un parcours hors du commun. Le format numérique vous permet de transporter cette émotion partout, transformant votre tablette en une fenêtre ouverte sur le génie littéraire du XIXe siècle. https://lerougeetlenoirpdf.site/ Le Rouge Et Le Noir Livre Numérique

Faites l’expérience d’une lecture poignante avec ce fichier numérique. Le livre est une exploration sensible de la vie. Ne manquez pas cette occasion de lire une œuvre qui capture la beauté tragique et comique de l’existence, à travers les yeux d’une enfant. https://lecoeurarireetapleurerpdf.site/ Le Cœur À Rire Et À Pleurer Fiche De Lecture

Sagan a inventé avec ce livre une nouvelle façon d’écrire et d’être, libre et désenchantée. Découvrez ce style révolutionnaire en lisant le texte intégral en PDF, et comprenez pourquoi ce petit roman a fait l’effet d’une bombe dans le paysage littéraire de l’époque. https://bonjourtristessepdf.site/ Bonjour Tristesse Pdf Ebook Gratuit

Ce livre est une célébration de la complexité des rapports humains. En version électronique, il est plus accessible que jamais. C’est une lecture qui vous fera vibrer, explorant les nuances subtiles entre l’amour familial et les incompréhensions générationnelles. https://lecoeurarireetapleurerpdf.site/ Le Cœur À Rire Et À Pleurer Version Numérique

Ce chef-d’œuvre est une exploration minutieuse des motivations humaines les plus secrètes. Stendhal est un psychologue de génie. Le format pdf rend cette œuvre monumentale accessible à tous les budgets, souvent gratuitement ou à faible coût, favorisant la diffusion de la culture littéraire auprès du grand public. https://lerougeetlenoirpdf.site/ Le Rouge Et Le Noir Livre Entier

La maîtrise narrative de Sagan est impressionnante pour une auteure si jeune, créant un récit parfaitement équilibré. Admirez cette construction littéraire en téléchargeant le livre en PDF, un format qui met en valeur la structure rigoureuse et l’enchaînement logique des événements dramatiques. https://bonjourtristessepdf.site/ Lire Bonjour Tristesse Pdf

Ce chef-d’œuvre est une preuve que la littérature peut changer la vie, ou du moins la vision qu’on en a. C’est puissant. Le fichier pdf est le vecteur de ce changement, apportant la puissance du texte stendhalien directement sur vos écrans pour une influence immédiate. https://lerougeetlenoirpdf.site/ Le Rouge Et Le Noir Chapitre Par Chapitre Pdf

Un récit qui oscille entre la lumière et l’ombre avec talent. Le livre à télécharger est une opportunité à saisir. C’est une œuvre qui vous fera vivre des moments forts, illustrant parfaitement la dualité de nos sentiments face aux souvenirs de notre enfance. https://lecoeurarireetapleurerpdf.site/ Maryse Condé Le Coeur À Rire Et À Pleurer Pdf

Laissez entrer un peu de lumière dans votre bibliothèque numérique avec ce titre incontournable de la scène littéraire française. Télécharger tout le bleu du ciel, c’est accepter de faire un voyage bouleversant aux côtés de personnages attachants, le tout avec le confort moderne de la lecture sur écran. https://toutlebleuducielpdf.site/ Tout Le Bleu Du Ciel Lecture En Ligne

Plongez au cœur des émotions contradictoires d’une jeune fille face au remariage potentiel de son père dans ce récit culte. La disponibilité du livre en format Bonjour Tristesse PDF facilite l’accès à cette œuvre majeure, vous permettant de la conserver dans votre bibliothèque numérique personnelle pour une relecture à tout moment. https://bonjourtristessepdf.site/ Bonjour Tristesse Texte Intégral Pdf

Sprachbarrieren sind dazu da, durchbrochen zu werden. Unsere PDF-Hilfen sind Ihr Werkzeug. Erreichen Sie den Status „fluent“, indem Sie sich den Herausforderungen der deutschen Sprache stellen und sie mit unserer Unterstützung meistern. https://becomingfluentingermanpdf.site/ German Plural Forms Pdf

Schenken Sie sich selbst Zeit für Kultur und Geschichte. Die Lektüre der Hausmärchen ist wie eine Reise in die Vergangenheit. Starten Sie diese Reise ganz bequem von Ihrem Sofa aus, indem Sie eine Grimms Märchen PDF auf Ihren Laptop oder Ihr Tablet laden. https://grimmsmarchenpdf.site/ Grimms Märchen Wer Wird Am Ende König

Wer die Berliner Schnauze liebt, findet in einem Traditional-Berlin Café Guide als PDF Orte, wo die Bedienung noch echt und unverfälscht ist und man den typischen Berliner Humor zum Kaffee gratis dazu bekommt. https://cafeinberlinpdf.site/ Learn German With Stories Café In Berlin Pdf

Lassen Sie sich helfen, die deutsche Grammatik zu entwirren. Unsere PDF-Hilfen sortieren das Chaos. Werden Sie fließend, indem Sie Struktur in Ihr Wissen bringen und Regeln sicher anwenden. https://becomingfluentingermanpdf.site/ Complete German Grammar Pdf

Die Märchenstraße in Deutschland ist ein beliebtes Reiseziel. Bereiten Sie Ihren Trip vor, indem Sie die Geschichten lesen, die dort spielen. Eine Grimms Märchen PDF auf dem Tablet ist der perfekte Reiseführer für literarische Entdeckungstouren. https://grimmsmarchenpdf.site/ Wie Singt Der Zaunkönig In Grimms Märchen

Für alle, die Geschichte nicht nur lernen, sondern fühlen wollen. Im Westen nichts Neues als PDF ist der Schlüssel. Erleben Sie den Ersten Weltkrieg durch die Augen der Betroffenen und verstehen Sie das Leid des Krieges. https://imwestennichtsneuespdf.site/ Erich Maria Remarque Im Westen Nichts Neues Pdf

Ein historisches Erlebnis bietet ein Golden-Twenties Café in Berlin Guide als PDF, der dich zu Orten führt, die den Glanz der 1920er Jahre bewahrt haben, mit Samtvorhängen, Kronleuchtern und klassischer Musik. https://cafeinberlinpdf.site/ Cafe In Berlin Book Free Download

Klassische Literatur ist oft schwer zugänglich, aber digitale Formate bauen Barrieren ab. Jeder mit Internetzugang kann teilhaben. Nutzen Sie diese demokratische Möglichkeit und laden Sie sich eine Grimms Märchen PDF, um Teil der globalen Lesergemeinschaft zu werden. https://grimmsmarchenpdf.site/ Grimms Märchen Buch

Möchten Sie Ihr literarisches Wissen auffrischen? Im Westen nichts Neues als PDF ist der ideale Einstieg. Schnell heruntergeladen, können Sie sofort mit dem Lesen beginnen und sich von der sprachlichen Wucht dieses Jahrhundertromans mitreißen lassen. https://imwestennichtsneuespdf.site/ All Quiet On The Western Front Full Story Pdf

Ein Ort für die ganze Familie, inklusive Hund, gesucht? Ein All-Welcome Café in Berlin Guide als PDF ist die Lösung für Großfamilienausflüge, bei denen wirklich jeder, vom Kleinkind bis zum Haustier, gut versorgt wird. https://cafeinberlinpdf.site/ Learn German With Stories: Café In Berlin Pdf

Jede Reise beginnt mit guter Vorbereitung, auch das Sprachenlernen. Unsere PDF-Sammlung ist Ihr perfektes Reisegepäck auf dem Weg zu „fluent in German“. Rüsten Sie sich mit Vokabeln und Grammatikwissen aus, um jede sprachliche Herausforderung zu meistern. https://becomingfluentingermanpdf.site/ German Reading Practice Pdf

Ein Ort, um neue Energie zu tanken, ist ein Wellness-Café in Berlin Guide als PDF, der dir Cafés in Yogastudios oder Spas zeigt, wo du nach dem Sport oder der Sauna einen gesunden Snack und einen Tee genießen kannst. https://cafeinberlinpdf.site/ Cafe In Berlin Ebook Download

Digitale Bücher vergilben nicht und bekommen keine Eselsohren. Sie bleiben immer frisch. Eine Grimms Märchen PDF ist eine Anschaffung für die Ewigkeit, die auch noch in vielen Jahren genauso gut lesbar ist wie heute. https://grimmsmarchenpdf.site/ Was Singt Der Zaunkönig In Grimms Märchen

Machen Sie sich das Lesen leicht mit der elektronischen Ausgabe. Wenn Sie Im Westen nichts Neues als PDF suchen, werden Sie hier fündig. Ideal für alle, die Platz im Bücherregal sparen wollen, aber nicht auf die großen Werke der Literatur verzichten möchten. https://imwestennichtsneuespdf.site/ Im Westen Nichts Neues Original Pdf

Ein Besuch im Museum macht müde Beine, und ein Museum-Café in Berlin Guide als PDF zeigt dir die schönsten Cafés in oder an den Museen der Stadt, wo du Kunst und Kulinarik in stilvollem Ambiente verbinden kannst. https://cafeinberlinpdf.site/ Cafe In Berlin Study Guide

Suchen Sie nach dem direkten Weg zum Ziel? Unsere PDF-Guides führen geradeaus. Erreichen Sie „becoming fluent in German“ ohne Umwege. https://becomingfluentingermanpdf.site/ German Phrasebook Pdf

Möchten Sie Ihre Deutschkenntnisse verbessern oder einfach nur klassische Prosa genießen? Die Sprache der Brüder Grimm ist ein wunderbares Übungsfeld. Am besten eignet sich hierfür eine digitale Ausgabe, wie etwa ein Grimms Märchen PDF, da Sie so unbekannte Wörter leicht markieren und nachschlagen können. https://grimmsmarchenpdf.site/ The Fisherman And His Wife Pdf

Ein Paradies für Schleckermäuler ist ein Dessert-Café in Berlin Guide als PDF, der den Fokus auf die süßen Begleiter legt und dir zeigt, wo es die besten Macarons, Eclairs oder Pralinen zum Kaffee gibt. https://cafeinberlinpdf.site/ Café In Berlin Pdf

Die Ästhetik der Sprache in den Grimmschen Märchen ist einzigartig. Althochdeutsche Einflüsse und volkstümliche Redewendungen machen den Reiz aus. Genießen Sie dieses sprachliche Kunstwerk in seiner vollen Pracht mit einer digitalen Grimms Märchen PDF Ausgabe. https://grimmsmarchenpdf.site/ Grimms Fairy Tales Illustrated Pdf

Möchten Sie sich intensiv mit dem Thema Krieg auseinandersetzen? Im Westen nichts Neues als PDF ist der beste Begleiter. Der Roman schönt nichts und ist gerade deshalb so wertvoll für das Verständnis von Geschichte. https://imwestennichtsneuespdf.site/ Besetzung Von Im Westen Nichts Neues 2022

Ein Ort für Teambesprechungen gesucht? Ein Team-Meeting Café in Berlin Guide als PDF zeigt dir Cafés mit großen Tischen und Reservierungsmöglichkeit, wo man in lockerer Atmosphäre Projekte besprechen kann. https://cafeinberlinpdf.site/ Cafe In Berlin Book Free Download

Möchten Sie Ihre Karrierechancen durch exzellente Deutschkenntnisse verbessern? Unsere PDF-Downloads sind der Schlüssel dazu. Lernen Sie, fließend und professionell zu kommunizieren, und nutzen Sie unsere Ressourcen, um das Ziel „becoming fluent“ effizient und sicher zu erreichen. https://becomingfluentingermanpdf.site/ Fluent In German In 3 Months Pdf

You can explore a tale that makes you scream. This PDF is a journey. It is a long road. The digital format is steady. calm and collected. https://youcanscreampdf.top/ You Can Scream Free Novel

I find that reading helps me empathize with others. A diverse archive of romance showcases different perspectives on love. I download PDF novels featuring characters from various backgrounds, helping me understand and appreciate different life experiences. https://anarchiveofromancepdf.top/ Ava Reid Archive Of Romance Pdf

Your next favorite story is just a click away with the In Your Dreams PDF version available for avid readers. This format is perfect for highlighting memorable passages and keeping the book safe in your cloud storage forever. https://inyourdreamspdf.top/ In Your Dreams Full Novel Download

The wait for a high-quality digital version of this masterpiece is finally over. You can now grab the An Arcane Inheritance PDF and immerse yourself in a narrative filled with suspense and supernatural twists. Perfect for tablet or smartphone reading, this story will keep you on the edge of your seat. https://anarcaneinheritancepdf.top/ An Arcane Inheritance Online Pdf

If you are looking for a convenient way to read on the go, the In Your Dreams PDF offers the perfect solution for avid readers. You can access the file quickly and start enjoying the intricate plot and character development immediately from your smartphone or tablet. https://inyourdreamspdf.top/ In Your Dreams Online Library

Uncover the dark secrets of a wealthy family. An Arcane Inheritance is a thriller with a magical twist, available as a PDF. This format is ideal for reading on the go. Download your copy today and see what lies hidden in the shadows of the estate. https://anarcaneinheritancepdf.top/ An Arcane Inheritance Epub Free

The In Your Dreams PDF is the smart reader’s choice. It combines the love of literature with the practicality of modern technology, creating the perfect reading solution. https://inyourdreamspdf.top/ In Your Dreams Pdf Online

Master the gold market with the Bluebird Gold PDF. This professional report offers expert insights and strategic advice for the modern, savvy investor today. Access this guide now to sharpen your market understanding and achieve your long-term financial goals and your own ultimate success. https://bluebirdgoldpdf.site/ Bluebird Gold Digital Download Link

Born of Trouble is a story of survival, strength, and the power of the human spirit. This inspiring and gritty narrative is now available for your digital library in pdf format. Witness the triumph of characters who refuse to be broken by their past. https://bornoftroublepdf.site/ Download Born Of Trouble Mobi

Experience the beauty of a romance written with care. The Love in Plane Sight PDF is available for download. This novel is a work of art. Get the digital edition today and appreciate the storytelling. https://loveinplanesightpdf.site/ Love In Plane Sight Reddit

Discover a novel that is perfect for romance fans everywhere. The Love in Plane Sight PDF is the digital edition you have been waiting for. It is a story filled with hope and love. Access the file today and start reading immediately. https://loveinplanesightpdf.site/ Love In Plane Sight Virtual Book

The Bluebird Gold PDF offers a comprehensive look at the precious metals industry. From historical data to modern strategies, this guide covers everything you need. Access this vital resource today to sharpen your financial skills and secure your future wealth. https://bluebirdgoldpdf.site/ Bluebird Gold Online Library

The Is This a Cry for Help PDF is your reading solution. This digital version is quick. Secure your file now. https://isthisacryforhelppdf.site/ Is This A Cry For Help Tolino

The writing in Born of Trouble is as beautiful as it is powerful. Experience the lyrical prose and the sharp dialogue in our new pdf edition. This is a book that will stay with you long after you’ve finished reading the final page. https://bornoftroublepdf.site/ Born Of Trouble Book Pdf Online

The Is This a Cry for Help PDF allows you to delve into the story immediately without waiting for delivery. This electronic version is crisp, clear, and ready for your e-reader. Download the file now and lose yourself in the captivating world created by the author. https://isthisacryforhelppdf.site/ Is This A Cry For Help Chapter 1 Pdf

Elevate your investment strategy with the Bluebird Gold PDF. This comprehensive report provides detailed insights into the gold sector, helping you identify new opportunities. Access this guide now to stay ahead of the curve and maximize your returns. https://bluebirdgoldpdf.site/ Bluebird Gold Romance Novel

Born of Trouble is a shining example of what modern fiction can achieve. This brilliant and evocative story is now available in a convenient pdf format. Experience the talent and the vision of an author who is truly pushing the boundaries of the form. https://bornoftroublepdf.site/ Science Fiction Pdf Library

The Is This a Cry for Help PDF allows you to read instantly. This digital version is great. Secure your download now and read. https://isthisacryforhelppdf.site/ Is This A Cry For Help Mobile Version

If you want a book that is easy to download and read, choose this. The Love in Plane Sight PDF is the ebook that is simple. It is a story that is accessible. Get your copy now and read simply. https://loveinplanesightpdf.site/ Love In Plain Sight Free

You ought to be a part of a contest for one of the finest sites on the web.

I most certainly will highly recommend this web site!

The use of foreshadowing in this novel is masterful. You can study the technique by reading The Book Thief PDF. It is a great resource for aspiring writers and literature students who want to see how a master storyteller constructs a compelling and emotional narrative arc.

Are you searching for a book that will stay with you for a lifetime? Look no further than this masterpiece. The Book Thief PDF is available for those who prefer digital convenience. It is a story that resonates across generations and borders, connecting us all. https://thebookthiefpdf.site/ The Book Thief Full Pdf

The Controller’s library contains books that are dangerous to the state. Access the Brave New World PDF to see which texts are forbidden. It is a meta-commentary on the power of literature to disrupt the status quo. https://bravenewworldpdf.site/ Ethics For A Brave New World John Feinberg Pdf

In a world that demands emotional conformity, Meursault is a rebel. He refuses to pretend. The Stranger is Albert Camus’ exploration of a man who becomes a martyr for the truth. The narrative is simple, yet the implications are vast. If you are looking for The Stranger PDF to help with your studies or for pleasure reading, this book is indispensable. It highlights the absurdity of human justice and the fragile nature of social bonds. https://thestrangerpdf.site/ Camus Philosophy The Stranger Pdf Worksheets

Новые онлайн казино – рейтинг и ТОП лучших сайтов для игры на деньги

Актуальный рейтинг новых онлайн казино. ТОП лучших сайтов для игры на реальные деньги: лицензия, честные условия, быстрый вывод средств и бонусы для игроков.

Новые онлайн казино – это игровые платформы, которые относительно недавно вышли на рынок и начали принимать игроков. Чаще всего речь идёт о проектах, запущенных в последние один-два года. Они активно развиваются, внедряют свежие технологии и стараются предложить условия, которые выгодно отличают их от более старых брендов.

Как формируются новые казино

Создание нового казино начинается с выбора лицензии, программного обеспечения и платёжных решений. После этого формируется бонусная политика, подбираются игровые провайдеры и настраиваются системы безопасности. Большинство новых казино ориентируются на международную аудиторию и сразу запускаются как онлайн-площадки с поддержкой разных валют и способов оплаты.

Рынок новых онлайн казино меняется достаточно быстро. Одни проекты активно развиваются, расширяют выбор игр и улучшают условия для игроков, другие, наоборот, теряют доверие из-за задержек выплат или непрозрачных правил. Поэтому рейтинг новых казино не может быть статичным – он должен регулярно пересматриваться и обновляться.

При составлении рейтинга учитываются только актуальные данные. Проверяется работа сайта, доступность платёжных систем, корректность бонусных условий и общее качество сервиса. Такой подход позволяет выделять действительно надёжные новые онлайн казино и исключать площадки, которые не соответствуют заявленным требованиям.

Почему важно выбирать казино из рейтинга

Современные новые онлайн казино используют защищённые протоколы передачи данных и сотрудничают с надёжными платёжными системами. Это снижает риск утечки информации и обеспечивает безопасность транзакций.

Новые онлайн казино с лицензией

Наличие лицензии – один из ключевых факторов при выборе нового онлайн казино. Даже если проект появился совсем недавно, лицензирование говорит о том, что площадка обязуется соблюдать определённые правила и стандарты. Для игрока это означает более высокий уровень защиты и прозрачности.

Новые казино чаще всего получают международные лицензии, которые позволяют работать с широкой аудиторией. При этом сама лицензия – не формальность, а инструмент контроля со стороны регулятора.

Какие лицензии встречаются у новых казино

У новых онлайн казино топ казино новые чаще всего можно встретить следующие типы лицензий:

• лицензия Curacao – самый распространённый вариант для новых проектов

• европейские лицензии (например, MGA) – встречаются реже, но считаются более строгими

• офшорные лицензии – используются для работы с международным трафиком

Каждая из них накладывает определённые обязательства на оператора и влияет на уровень доверия со стороны игроков.

The psychological thriller that inspired modern cinematic masterpieces, this novella delves into the madness that isolation can breed. As Marlow draws closer to Kurtz’s inner station, the narrative becomes increasingly dreamlike and disturbing. Readers today often prefer a Heart of Darkness PDF version to access this timeless story on their tablets or e-readers during their commute. The themes of moral ambiguity and the corruption of power are just as relevant today as they were at the turn of the 20th century. Conrad’s intricate prose demands attention, rewarding those who brave the journey. https://heartofdarknesspdf.site/ Conrad The Heart Of Darkness Pdf

The transition from the playful antics of childhood to the serious responsibilities of adulthood is captured perfectly in this novel. We watch the March sisters make mistakes, fall in love, and find their places in the world. To follow their path, you can download a Little Women PDF. This format is ideal for late-night reading sessions when you just can’t put the book down. The soft glow of a screen can illuminate the heartwarming and sometimes heartbreaking world of the March sisters, making it a truly immersive experience. https://littlewomenpdf.site/ Little Women Play Script Pdf Free Download

The symbolism of the “Pearl of the World” has been interpreted in dozens of ways: as a soul, as original sin, as capitalism, as the atomic bomb (considering the era). This ambiguity is its strength. It invites the reader to project their own meaning onto it. When you download the pearl pdf, you are engaging with a text that changes depending on who reads it. For a religious reader, it is a parable of idolatry. For a Marxist, a parable of class struggle. This versatility keeps the book in print and in the classroom decades after its publication. https://thepearlpdf.site/ The Pearl Study Guide Pdf Download

The novella’s brevity makes it perfect for a single-sitting read. Unlike Steinbeck’s massive epics, this story can be consumed in a few hours, yet it leaves an impression that lasts for years. Its compact nature appeals to modern readers with busy schedules. Finding a the pearl pdf online is a common way for commuters and travelers to access this literary gem. It provides a complete, emotional narrative arc without the commitment of a 500-page novel, delivering a powerful punch of literary brilliance in a small package. https://thepearlpdf.site/ The Pearl John Steinbeck Study Guide Pdf

Revisiting the March family home is like visiting old friends who always welcome you with open arms. The trials and tribulations of the sisters, set against the backdrop of a divided nation, offer a poignant look at resilience. If you are eager to introduce this story to a new generation, or simply want to enjoy it yourself, a digital edition is a great choice. You can easily find a Little Women PDF to read on a variety of devices. This flexibility ensures that the legacy of Louisa May Alcott continues to thrive in the digital era, reaching readers everywhere. https://littlewomenpdf.site/ Little Women Test Pdf

Hi there this is kinda of off topic but I was wondering if blogs use WYSIWYG editors or if you have to manually code with HTML. I’m starting a blog soon but have no coding skills so I wanted to get advice from someone with experience. Any help would be greatly appreciated!

РиоБет

Throughout the narrative, the environment reflects Kino’s internal struggle. The sea, once a source of life, becomes a place of danger. The desert is a place of purgatory. The mountains are the site of judgment. Literary geographers might use the pearl pdf to map out Kino’s physical and spiritual journey. The movement from the coast to the high interior mirrors the escalation of the stakes. Every step away from the sea is a step further into the trap of his own making.

The novella’s brevity makes it perfect for a single-sitting read. Unlike Steinbeck’s massive epics, this story can be consumed in a few hours, yet it leaves an impression that lasts for years. Its compact nature appeals to modern readers with busy schedules. Finding a the pearl pdf online is a common way for commuters and travelers to access this literary gem. It provides a complete, emotional narrative arc without the commitment of a 500-page novel, delivering a powerful punch of literary brilliance in a small package.

The sheer density of the imagery in this book is astounding. Light does not always mean good, and darkness does not always mean evil. Conrad subverts these traditional symbols to create a more complex moral landscape. A Heart of Darkness PDF is the perfect tool for unraveling these symbolic knots. The novella is a rich tapestry of meaning that requires careful attention. It is a book that challenges you to think deeply about the nature of good and evil.

A telegram announces a death, but the protagonist feels nothing. The Stranger by Albert Camus begins with apathy and ends with a revelation. It is a journey through the absurd, set against the vibrant backdrop of Algeria. If you are looking for The Stranger PDF to complete a reading assignment or to expand your literary horizons, this book is essential. It compels the reader to confront the naked reality of existence without the comfort of societal lies.

The ending of the book is not just tragic; it is an act of liberation. By throwing the pearl away, Kino reclaims his soul, albeit at a terrible price. He refuses to play the game any longer. This act of defiance is powerful. Readers looking for the pearl pdf often want to revisit this specific moment of release. It suggests that true freedom comes from rejecting the values imposed by a corrupt society, even if that rejection leaves you with nothing but your life.

The character of Meursault has fascinated readers for generations. Is he autistic, sociopathic, or simply honest? The Stranger by Albert Camus leaves the interpretation open. If you are searching for The Stranger PDF, you are engaging with a text that refuses to label its protagonist. It invites you to look at the world through eyes that see only what is physically there, without the filter of social expectation.

“The Pearl” is a book about limits. The limits of luck, the limits of love, and the limits of human endurance. Kino pushes past all of them and breaks. It is a harrowing examination of what happens when a man refuses to submit to his fate. For a deep dive into existentialist themes in American literature, the pearl pdf is a key text. Kino’s struggle is the struggle of every person who has ever tried to assert their will against an indifferent universe.

Marlow’s journey is often interpreted as a descent into hell. The stations he passes are like circles of suffering. This allegorical reading adds another layer of depth to the story. If you are interested in this interpretation, a Heart of Darkness PDF can help you track the religious and mythological references in the text. The book is a profound spiritual inquiry disguised as an adventure story. It is a work that speaks to the soul.

The character of Meursault has fascinated readers for generations. Is he autistic, sociopathic, or simply honest? The Stranger by Albert Camus leaves the interpretation open. If you are searching for The Stranger PDF, you are engaging with a text that refuses to label its protagonist. It invites you to look at the world through eyes that see only what is physically there, without the filter of social expectation.

I’m not sure why but this blog is loading very slow for me. Is anyone else having this issue or is it a problem on my end? I’ll check back later and see if the problem still exists.

https://egaist.info/investicii-v-kriptovaljuty-rekomendacii-bezopasnost-i-analiz/

I’m gone to say to my little brother, that he should also pay a visit this weblog on regular basis to obtain updated from most recent news.

http://www.bigfootpodiatry.com.au/innovations-de-lapk-iron-tv-pro-5-1-focus-utilisateur/

Step into the emotional world of Great Big Beautiful Life. Emily Henry writes with a depth that is truly impressive. The epub format is the best way to experience this story on the go. It is a great, big, portable adventure that fits in your hand. The narrative is beautiful and inspiring, offering a fresh perspective on love. This is a book that you will want to share with everyone. Download the ebook and start the journey today. https://greatbigbeautifullifeepub.site/ Emily Henry Great Big Beautiful Life Vk

Ashley Winstead returns with a vengeance in her new book, appropriately titled This Book Will Bury Me. It is a promise and a threat wrapped in a beautiful cover. Readers who enjoy the portability of an epub will appreciate how easily this story fits into a busy lifestyle. You can steal a few pages on your lunch break or immerse yourself for hours on a flight. The plot is tight, and the character arcs are satisfyingly complex. It is the sort of book that reminds you why you fell in love with reading in the first place. Make sure you have your e-reader charged, because this is a story you will want to devour in one sitting. https://thisbookwillburymeepub.site/ This Book Will Bury Me Ending Explained

From the outside, Shay looks like the perfect wife, but inside, she is a warrior preparing for battle. The death of her childhood friend forces her to team up with a true-crime podcaster. This dynamic duo drives the plot of this intense novel. Securing the The Last Housewife epub ensures you can read this fast-paced story anywhere. It is a dark, twisting journey into the heart of a misogynistic cult in upstate New York. Winstead’s writing is sharp and unyielding, making this a standout title in the psychological thriller genre. https://thelasthousewifeepub.site/ The Last Housewife Novel

Read the latest from Devney Perry, Shield of Sparrows. The epub version is available now. Digital books are convenient and light. Perry’s story is full of love. The digital copy ensures a good reading experience. Whether you are busy or relaxed, this ebook fits your life. Download it and start reading. https://shieldofsparrowsepub.site/ Shield Of Sparrows Epub Vk

Unlock the joy of reading with Great Big Beautiful Life. Emily Henry is a storyteller of the highest caliber. The epub version of her new book is perfect for anyone who loves digital reading. It offers a great reading experience with customizable features. The story is a beautiful journey through the highs and lows of life. It is a great, big, emotional adventure that is not to be missed. Get the ebook today and start reading one of the best books of the year. https://greatbigbeautifullifeepub.site/ Emily Henry New Book Great Big Beautiful Life

Ashley Winstead’s This Book Will Bury Me is a weapon. It is a book that fights. The epub version is the holster. Keep it ready. The story is dangerous. It is a book that will bury you in its threat. If you want a digital book that protects, this is the one. Get the epub and defend. https://thisbookwillburymeepub.site/ Similar Books To This Book Will Bury Me

Dive into the latest romantic masterpiece, Shield of Sparrows, written by Devney Perry. If you love reading on your Kindle or iPad, the epub version is exactly what you need. This format offers a crisp, clean reading experience that lets the story shine. Perry’s characters are complex and lovable, making it hard to put the device down. The digital copy ensures that you can take this story with you on vacations or business trips without weighing down your luggage. Experience the convenience of digital reading with this top-tier novel. https://shieldofsparrowsepub.site/ Shield Of Sparrows Free Download Pdf

Наткнулся на отличный обзор инновационной кухонной техники. Речь о варочных панелях Elica NikolaTesla со встроенной вытяжкой. Очень подробный разбор характеристик и преимуществ для современной кухни. Рекомендую почитать всем, кто планирует ремонт или обновление техники. Подробности по ссылке в источнике.

Бизнес Online обзор техники

Imagine a book that feels like a warm hug and a heartbreaking goodbye all at once. That is the magic contained within Great Big Beautiful Life. Emily Henry has crafted a narrative that is both expansive and intimately personal. For the modern reader who loves convenience, securing the epub edition allows for instant access to this beautiful world. You can highlight your favorite quotes and carry this emotional rollercoaster in your pocket wherever you go. The story resonates deeply, making it a must-read for fans of the genre. If you are looking for your next five-star read, look no further than this digital gem that explores what it means to truly live.

When the mood for a great romance strikes, Shield of Sparrows by Devney Perry is the perfect choice. Opting for the epub format means you can start reading immediately without waiting for delivery. This story is a beautiful addition to Perry’s bibliography, featuring her signature blend of heart and heat. Digital reading allows you to customize fonts and margins, making the experience comfortable for your eyes. If you love stories that make you feel everything, this is the book for you. Ensure you have the digital file loaded on your device for instant access to this incredible world.

Devney Perry’s Shield of Sparrows is a stunning book. The epub format is the most convenient way to enjoy it. You can download it instantly and start reading. Perry’s characters are deep and real. The digital edition is perfect for reading anywhere. Whether you are at home or traveling, this ebook is a must-have. Don’t miss this incredible romance. Get the digital version now.

Do you find yourself forgetting German words as soon as you learn them? Context is the cure. Instead of a list, look for a short stories in German PDF or, better yet, a curated anthology. When you read a word in a story, you remember the situation, the character, and the emotion associated with it. This creates a stronger memory hook. Olly Richards’ book utilizes this concept to help you retain over 1,000 common words. By the time you finish the eight stories, you will have a much richer vocabulary without ever having done a drill. https://shortstoriesingermanpdf.site/ Short Stories In German For Beginners Free Epub

If you want to understand German culture, you need to read. While these stories are written for learners, they reflect the cultural nuances of the language. A simple short stories in German PDF might miss these subtleties. The way characters interact, the idioms they use, and the settings all provide cultural context. Language and culture are inseparable. Learn both at the same time by diving into stories that are rich in linguistic and cultural detail. https://shortstoriesingermanpdf.site/ Short Stories In German: New Penguin Parallel Texts

La parole est à l’accusé, et elle porte loin. Ce livre est un événement. La version epub du journal d’un prisonnier est disponible pour tous. Nicolas Sarkozy y défend son intégrité avec panache. Un livre à lire absolument.

Better Than the Prom is a story about finding your person. Liz finds hers in the most unexpected place. If you are looking for the PDF, you are looking for connection. The book celebrates the bond between two people.

Si vous aimez les thrillers qui vous retournent l’estomac, lisez “Le Boyfriend”. Freida McFadden ne prend pas de gants dans ce récit brutal et fascinant. Ce roman est disponible en téléchargement epub pour une expérience de lecture optimale. L’intrigue est complexe, jouant sur les peurs et les doutes de chacun. C’est un livre qui se dévore, page après page, jusqu’à l’explosion finale. Une lecture numérique indispensable pour les fans de l’autrice.

Better Than the Prom is more than just a book; it is an experience. If you are searching for the PDF, you are ready to embark on that experience. The story draws you in and holds you captive. It is a page-turner in the truest sense of the word. You won’t be able to stop reading until you reach the very end.

Voici le livre qui remet les pendules à l’heure selon Nicolas Sarkozy. Une lecture indispensable pour comprendre sa ligne de défense et sa psychologie. Le fichier epub du journal d’un prisonnier est très demandé par les lecteurs connectés. L’ouvrage est un mélange de récit factuel et de réflexions philosophiques sur l’épreuve. C’est un témoignage poignant sur la dignité face à l’accusation.

Effective language acquisition happens when you are so absorbed in the content that you forget you are studying. While a scattered short stories in German PDF collection can be hit-or-miss, a cohesive anthology ensures consistent quality. This specific volume is designed to support self-learners by providing glossaries and bilingual word lists exactly when you need them. You will encounter the most common words used in Germany today, helping you build a robust foundation. By finishing a complete story, you gain a sense of achievement that simple exercises cannot provide. Make reading a central part of your German learning strategy and watch your comprehension soar.

Sei alla ricerca di una storia che ti rimanga dentro per sempre? Una vita come tante è la risposta. La ricerca di un PDF o di una copia digitale dimostra la voglia di confrontarsi con questo gigante della letteratura. Hanya Yanagihara ha creato un personaggio, Jude, che è impossibile non amare e compatire. Leggere su un dispositivo elettronico ti permette di affrontare la lunghezza del libro con agilità, senza perdere nulla della profondità del testo. Non esitare a iniziare questo viaggio letterario che ha commosso milioni di persone. https://unavitacometantepdf.site/ Foto Copertina Una Vita Come Tante

Un segreto che nessuno osava immaginare in “L’ultimo segreto”. Robert Langdon lo svelerà. La scelta del pdf è ottima. La trama è ben costruita. Preparati a una lettura indimenticabile. https://lultimosegretopdf.site/ L’ultimo Segreto Dan Brown Pdf

La narrativa di Saint-Exupéry è un ponte tra la realtà e il sogno, un luogo dove è possibile incontrare se stessi attraverso gli occhi di un bambino venuto dalle stelle. La ricerca di il piccolo principe pdf è un modo per attraversare questo ponte in qualsiasi momento della giornata. Ci insegna che bisogna sopportare qualche bruco se si vogliono vedere le farfalle, una metafora bellissima sulla necessità di accettare i lati meno piacevoli della vita e delle persone per poterne apprezzare poi la bellezza e la trasformazione.

Un libro che è un viaggio nel cuore delle tenebre e della luce. Una vita come tante è il romanzo che devi leggere. Cercare il PDF significa voler scoprire la storia di Jude. La versione digitale ti offre la possibilità di leggere ovunque, rendendo ogni momento speciale. Hanya Yanagihara ha scritto un libro che ti segnerà per sempre. Scopri le vite intrecciate dei quattro amici e preparati a un’esperienza emotiva che ti lascerà profondamente cambiato.

Thank you for another excellent post. The place else may anybody get that kind of info in such an ideal way of writing? I have a presentation next week, and I am on the search for such information.

регистрация банда казино

Sei alla ricerca di un romanzo che sappia scuoterti nel profondo e lasciare un segno indelebile nella tua memoria? Il capolavoro di Hanya Yanagihara racconta la storia struggente di quattro amici a New York, legati da un affetto indissolubile e da segreti inconfessabili. Molti lettori cercano la versione digitale di Una vita come tante in PDF per portare sempre con sé, su tablet o smartphone, le oltre mille pagine di questa epopea emotiva. Scopri la comodità di avere sempre a portata di mano la storia di Jude e dei suoi compagni, immergendoti in una narrazione che esplora i limiti della sopportazione umana e la forza salvifica dell’amicizia.

La tensione è alle stelle in “L’ultimo segreto”, dove ogni secondo conta. Robert Langdon deve risolvere un puzzle mortale per salvare innocent. La versione pdf del libro è molto apprezzata dai lettori digitali. La storia è un mix esplosivo di azione, cultura e mistero. Non perdere l’opportunità di vivere un’avventura che ti lascerà col fiato sospeso fino all’ultima parola.

Новости России и Мира С линии фронта поступают сообщения об увеличении гуманитарной помощи населению освобожденных территорий. Российские волонтеры доставляют продукты питания, медикаменты и предметы первой необходимости. Организуются пункты временного размещения для беженцев.

Avia Masters de BGaming es un juego crash con RTP del 97% donde apuestas desde 0,10€ hasta 1.000€, controlas la velocidad de vuelo de un avion que recoge multiplicadores (hasta x250) mientras evita cohetes que reducen ganancias a la mitad, con el objetivo de aterrizar exitosamente en un portaaviones para cobrar el premio acumulado

feg.org.es

Avia Masters de BGaming es un juego crash con RTP del 97% donde apuestas desde 0,10€ hasta 1.000€, controlas la velocidad de vuelo de un avion que recoge multiplicadores (hasta x250) mientras evita cohetes que reducen ganancias a la mitad, con el objetivo de aterrizar exitosamente en un portaaviones para cobrar el premio acumulado

feg.org.es

The dark romance genre has a new standard bearer. This book pushes the boundaries of what is acceptable, exploring the darkest fantasies of its characters. Whether you read a physical copy or a Haunting Adeline PDF, the experience is intense. The book challenges you to suspend your disbelief and enter a world where the villain gets the girl. It is a controversial stance, but one that is explored with depth and nuance. The emotional rollercoaster of the story is worth every second of reading time. https://hauntingadelinepdf.site/ Haunting Adeline Saga Pdf Español

The propaganda war is just as deadly as the actual combat in this thrilling conclusion to the saga. Katniss must perform for the cameras while hiding her true shattered self from the public eye. Reading the Mockingjay PDF on your tablet brings the vibrant details of Panem to life. Digital books are an eco-friendly way to enjoy your favorite series without adding bulk to your bag. This novel provides closure to the burning questions raised in the first two books. Prepare for a story that refuses to offer easy answers or simple happy endings. https://mockingjaypdf.site/ Mockingjay Pdf Book

Parsons Manor is a character that breathes and watches. The setting of the book is integral to the plot, creating a sense of isolation that is terrifying. Readers looking for the Haunting Adeline PDF are often drawn by the promise of a spooky, atmospheric read. The diary entries provide a historical context that makes the modern-day events feel even more significant. It is a story about the cycles of abuse and the difficulty of breaking free. H.D. Carlton has created a world that is immersive and terrifyingly real. https://hauntingadelinepdf.site/ Haunting Adeline Epub Reddit Free Download

The setting of the book, a small college town in Ohio, adds to the feeling of claustrophobia that Lydia feels. Everyone knows everyone, and the Lees are always under scrutiny. This atmosphere is perfectly captured by Ng. If you are looking for the Everything I Never Told You PDF, you will find a text that is rich in atmospheric detail. The setting becomes a character in itself, influencing the actions and feelings of the family. It is a story about the difficulty of finding a safe harbor in a judgmental world. https://everythinginevertoldyoupdf.site/ Everything I Never Told You Pdf Download

The fashion team, led by Cinna’s influence, continues to use Katniss’s image to rally the troops. Even in war, style and perception are tools of the trade. Read about the final transformation of the Mockingjay in the PDF version of the book. Digital formats allow for a clutter-free reading experience, letting the imagery take center stage. The legacy of the characters we lost in previous books is felt strongly here. It is a tribute to the impact one person can have on the world. https://mockingjaypdf.site/ Mockingjay Pdf File Download

The foreshadowing in the book is subtle and clever. Re-reading it reveals new layers. The Empire of Storms PDF is great for a second pass. You see the clues you missed the first time. It is a well-constructed mystery. https://empireofstormspdf.site/ Empire Of Storm Epub Vk

Legacy and destiny are central themes that drive the characters forward. They are fighting not just for themselves, but for the future. The Empire of Storms PDF is a portal to a world where these high concepts are explored through personal stories. The writing is philosophical without being preachy. It adds a layer of depth that elevates the genre.

From the first sentence to the last, Everything I Never Told You holds the reader in a tight grip. It is a story of suspense and sorrow. If you are looking for the PDF, you are about to discover why Celeste Ng is one of the most important writers of her generation. It is a book that defines a genre. It is a story you will never forget.

The search for the Everything I Never Told You PDF ends here. Dive into the world of the Lee family and discover the secrets that lie beneath the surface. It is a book that will captivate you from the first page. It is a story of profound beauty and sadness. It is a must-read.

Ultimately, this book is about the triumph of hope over despair. Aelin’s refusal to give up, despite the overwhelming odds, is the core message. Whether you read it in print or via a Queen of Shadows pdf, that message shines through. It encourages readers to find their own inner strength. The Fireheart is not just a nickname; it is a symbol of burning bright against the encroaching dark. It is a powerful, resonant story that defines the modern young adult fantasy genre. https://queenofshadowspdf.site/ Queen Of Shadows Free Epub

McCarthy’s The Road is a novel of sensory details: the smell of wet ash, the sound of the wind, the feeling of bone-deep cold. It tells the story of two survivors in a ruined America. The narrative is episodic, following their daily struggle to keep moving south. It is a masterpiece of atmospheric writing. For students of literature, having a pdf copy can be a great asset for annotating and tracking the recurring motifs of fire, grayness, and blindness. This is a book that strips life down to its barest essentials. https://theroadpdf.site/ The Road Cormac Mccarthy Epdf

Sarah J. Maas has a gift for writing dialogue that snaps with wit and tension. The banter between Aelin and her court provides much-needed levity amidst the darkness of the plot. Reading the text via a Queen of Shadows pdf allows you to appreciate the rhythm of the conversations. The humor is sharp and often used as a defense mechanism, which fits the traumatized nature of the characters perfectly. It makes them feel human and relatable, despite their magical abilities and royal titles. https://queenofshadowspdf.site/ 5E Shadow Of The Dragon Queen Pdf

The gray world of The Road is one of the most memorable settings in fiction. McCarthy creates an atmosphere of total despair, which makes the small moments of kindness feel miraculous. The father and son are the heart of the story. This book is widely acclaimed and studied. Students and book clubs often utilize the road pdf for easy distribution and discussion. It is a text that challenges the reader to find hope in the darkest of places.

The novel is a testament to the endurance of the human spirit. If you are looking for a story that will challenge and change you, finding a Beloved PDF is the first step. It is a book that demands to be felt as much as read. The digital format ensures that this essential piece of world literature is available to anyone with a device, preserving the legacy of Toni Morrison and the millions of stories she sought to honor through her work.

The brutality of the Valg and the darkness of the magic involved makes this a mature read. It deals with themes of possession, slavery, and torture in a way that is serious and impactful. A Queen of Shadows pdf captures this dark tone perfectly. The villains are not cartoonish; they are genuinely terrifying and sadistic. This makes the heroes’ struggle feel desperate and their victories precious. It is a story where survival is not guaranteed, and every win comes with a cost.

доставка цветов москва недорого Курьерская служба свежих цветов

To truly understand the Gothic genre, you must read this book. A Wuthering Heights PDF is an essential file for any student of literature. It contains all the tropes: the castle-like house, the damsel in distress (who is actually quite fierce), the tyrant, and the supernatural. The digital version allows you to checklist these elements as you read. It is a textbook example of the genre that broke the mold. Having it in a portable format means you can study the mechanics of Gothic fiction wherever you go. https://wutheringheightspdf.site/ Wuthering Heights Full Pdf

This is the ultimate comfort read for anyone who loves love. The progression from enemies to friends to lovers is handled with expert care. If you are looking for a Better Than the Movies PDF, you are in for a treat with this heartwarming file. It is a book that teaches us that we are the directors of our own lives, and the unscripted moments are usually the best parts. https://betterthanthemoviespdf.site/ Better Than The Movies Pdf Download Vk

https://auto.qa/showrooms/

где купить самые дешевые цветы в москве Срочные цветы курьер недорого

Aesthetic Files Здесь я делюсь не только обзорами и мнениями, но и частичкой своей жизни. Мои фотографии, мои мысли, мои переживания – это все формирует общую картину Aesthetic Files. Это пространство, где можно отдохнуть от суеты, найти вдохновение и просто почувствовать себя частью чего-то большего. Добро пожаловать!

The relationship between fathers and sons is the emotional core of the story. The desire to please the father drives the plot. It is a universal theme that resonates with everyone. Whether you are a son or a father, you will see yourself in this book. An East of Eden PDF is a great way to share the book with family members for a shared reading experience. Our platform offers discussion points specifically for fathers and sons, helping to bridge generational gaps through literature. We facilitate meaningful conversations through the text. https://eastofedenpdf.site/ The East Of Eden Pdf

The evolution of the “enemies” label in this book is fascinating to watch. Liz and Wes have a banter that masks a deep underlying affection. If you are searching for a PDF version, you are on the path to a great read. It is a story that shows how thin the line between love and hate really is, and how wonderful it is to cross it. https://betterthanthemoviespdf.site/ Better Than The Movies Online Pdf Download

It is a truth universally acknowledged that a reader in possession of a tablet must be in want of a good ebook. The story of the Bennet family is the ultimate comfort read for many. If you want to escape into a world of empire waists and intricate social rules, this is the book for you. Searching for a Pride and Prejudice PDF reveals just how popular this title remains. Our site is dedicated to the novel, helping you navigate the text and its many layers. Enjoy the convenience of modern technology while devouring a classic that defined the romance genre. https://prideandprejudicepdf.site/ Pride And Prejudice Novel Pdf Free

There is no book quite like East of Eden. It is a universe unto itself. Once you enter the Salinas Valley, you never really leave. It changes how you see the world. If you haven’t entered yet, find a copy. An East of Eden PDF is your ticket in. Our website is the visitor center for this universe, providing maps, guides, and history. We welcome you to the world of John Steinbeck and the Trask family. https://eastofedenpdf.site/ East Of Eden Mobi Download