When sourcing or producing garments, the last thing any brand wants is shrinkage surprises after the first wash. Whether you’re manufacturing t-shirts, workwear, or technical textiles, ensuring dimensional stability is key to quality control. That’s where ISO 3759 steps in.

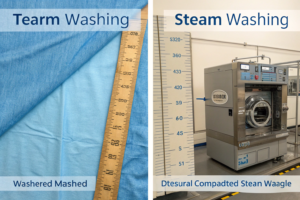

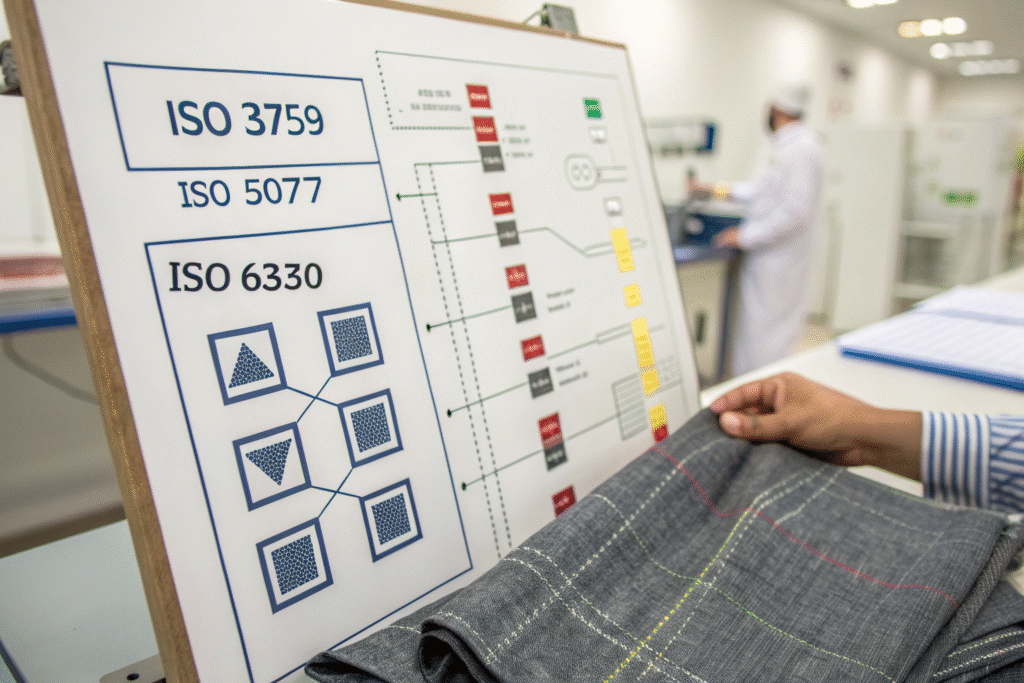

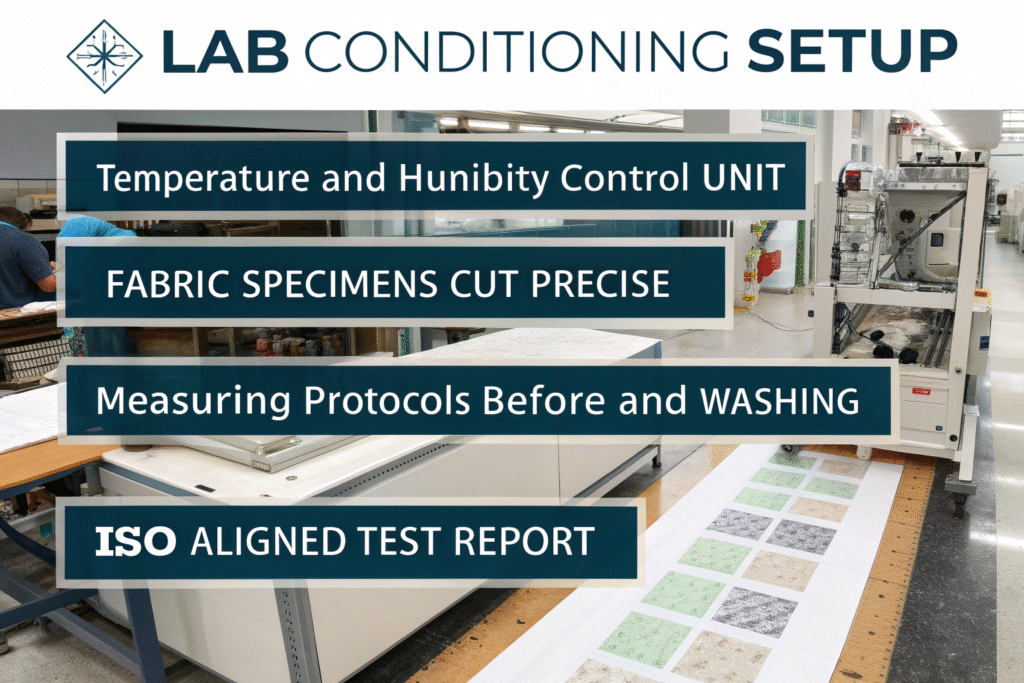

ISO 3759 defines the standardized preparation, conditioning, and measurement of fabrics for dimensional change testing. It’s the foundation upon which accurate shrinkage or growth tests like ISO 5077, ISO 6330, or ISO 7771 are based.

In this article, we’ll explore why ISO 3759 is indispensable in dimensional stability testing, how it ensures consistency across labs and supply chains, and how brands and mills can implement it to avoid costly returns or reprocessing.

What Is ISO 3759 and Why Does It Matter?

ISO 3759:2011 is the international standard that defines how textile specimens should be prepared, conditioned, marked, and measured for dimensional change assessments.

Key Purposes:

- Establishes pre-test conditioning environment (temp/humidity)

- Standardizes specimen marking techniques

- Ensures accurate pre- and post-treatment measurements

- Works in tandem with shrinkage testing methods like:

- ISO 5077 (dimensional change in woven/knit fabrics)

- ISO 6330 (domestic washing)

- ISO 7771 (dry cleaning)

💡 Without ISO 3759, dimensional stability data would be unreliable, as slight changes in preparation or measurement methods can skew shrinkage percentages significantly.

How Does ISO 3759 Ensure Reliable Fabric Shrinkage Results?

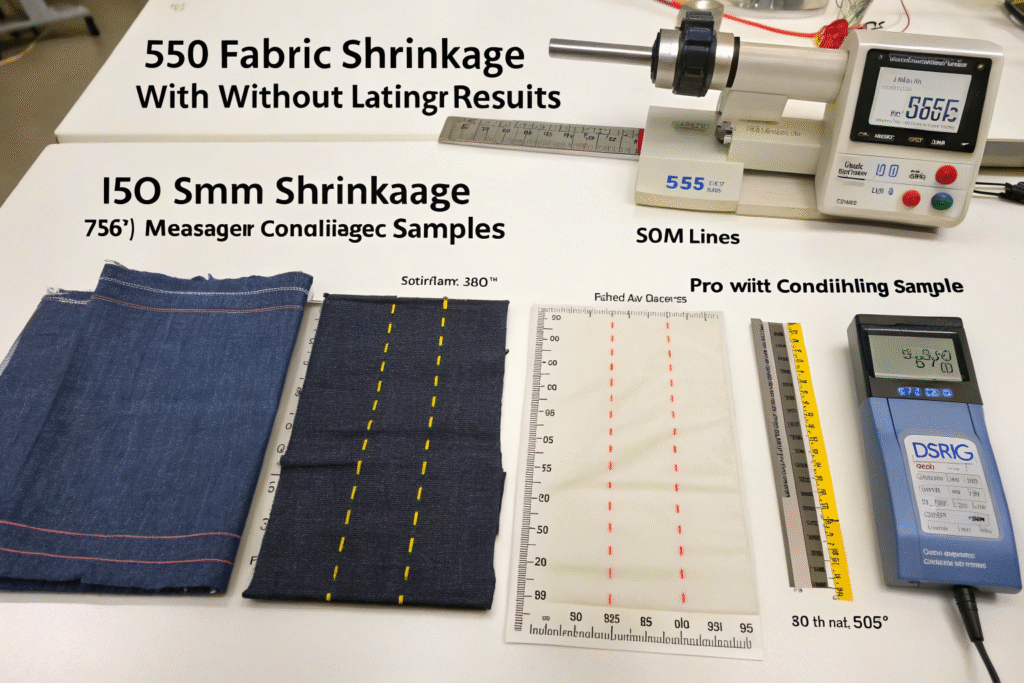

ISO 3759 creates the controlled baseline for fabric dimensional change testing. Even if a garment is only off by a few millimeters, that could mean size grading failures or fit complaints.

ISO 3759 Key Protocols:

| Procedure | Purpose |

|---|---|

| Pre-conditioning (20°C, 65% RH for 24 hrs) | Stabilizes fabric before measuring |

| Marking reference points | Enables repeatable measurement (usually 500 mm lines) |

| Post-treatment reconditioning | Ensures fabric is in moisture equilibrium |

| Use of accurate measuring tools | Avoids tape distortions or tension errors |

By eliminating variables like ambient humidity or manual errors, ISO 3759 ensures that the actual shrinkage—or stretch—is due to the treatment method, not external influences.

✅ For example, a 2% shrinkage claim in ISO 5077 is only valid if the sample was prepped and measured according to ISO 3759.

Why Should Brands, Labs, and Mills Care About ISO 3759?

Dimensional instability causes headaches throughout the textile supply chain:

-

Brands face returns and negative reviews if garments shrink or deform after purchase

-

Garment makers risk poor grading, cutting errors, and warranty disputes

-

Mills may fail QA if shrinkage tests are inconsistent or unverifiable

Benefits of Following ISO 3759:

-

📏 Repeatability: Any lab globally can reproduce your results

-

🔬 Validation: Ensures third-party lab tests align with in-house testing

-

🧵 Process Optimization: Detects fabric finish issues (e.g., tension, heat-set problems)

-

📦 Compliance: Required for ISO-certified fabric or finished product exports

At Fumao Fabric, we conduct shrinkage testing weekly on our cotton, polyester, and stretch fabrics using ISO 3759 + ISO 5077 protocols. Our reports include:

- Shrinkage percentages in warp, weft, and diagonal directions

- Pre-/post-wash fabric weight, width, and GSM

- QR-code lab validation for buyer transparency

How to Implement ISO 3759 in Fabric Sourcing and QA

If you’re a buyer or fabric developer, you don’t need to memorize the ISO standard—but you do need to verify your supply chain follows it.

Ask These Questions:

- ❓ Is ISO 3759 used to prep shrinkage samples before ISO 5077/6330/7771 tests?

- 📎 Are lab reports showing conditioning times, contact angles, and line distances?

- 📐 Is your mill using calibrated templates or digital marking frames?

- 🧪 Do they test before bulk production or post-finishing?

💡 Tip: Request 1-meter lab dips with dimensional stability test reports using ISO 3759/5077. This will show how the fabric behaves after wash and help you grade patterns properly.

Conclusion

ISO 3759 is not just another textile lab protocol—it’s the unsung hero of accurate dimensional stability testing. It lays the foundation for all reliable shrinkage, stretching, or wash behavior data across the industry.

If your garments need to pass strict size tolerance standards, or if you’re exporting to countries requiring ISO verification, implementing ISO 3759 is non-negotiable.

At Fumao Fabric, all our dimensional change testing—from single jersey to heavy cotton twill—is conducted under ISO 3759 preparation conditions. We provide buyers with traceable, lab-backed results that reflect real-world behavior—wash after wash.

📩 Need ISO 3759-tested fabric for your next project? Contact our QA team at elaine@fumaoclothing.com to get started.