When it comes to technical outerwear, performance isn’t optional—it’s expected. Whether you’re designing hiking gear, sports jackets, cycling tops, or military-grade outer layers, lightweight mesh fabrics play a critical role in enhancing breathability, reducing weight, and improving moisture management. But for sourcing professionals and brand owners, the challenge is clear: Where can you find the right mesh fabric that checks all the boxes of weight, quality, and durability?

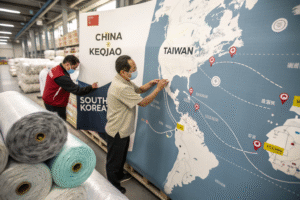

The best lightweight mesh fabrics for technical outerwear come from suppliers specializing in high-denier yarn control, functional finishing (anti-bacterial, UV, DWR), and integrated quality testing. Top sourcing hubs include Keqiao (China), Taiwan, and select Korean mills offering nylon, polyester, and spandex blends optimized for outerwear layering.

In this guide, I’ll break down the best global sourcing zones, fiber choices, key specs, and supplier vetting tips so your next outerwear line is breathable, durable, and built to perform.

Which Mesh Fabric Types Are Ideal for Technical Outerwear?

Not all mesh fabrics are created equal. Some are engineered for static structure and UV blocking. Others stretch and wick moisture in high-impact zones. Understanding which mesh type aligns with your technical outerwear use case is crucial.

The ideal mesh fabrics for outerwear are warp-knit polyester, tricot, spacer mesh, and lightweight stretch meshes, depending on the jacket’s functional zones—underarms, lining, vents, or shell reinforcement.

What Are the Most Common Technical Mesh Structures?

| Mesh Type | Key Feature | Best Use Case |

|---|---|---|

| Tricot Mesh | Fine-gauge, soft, stable | Linings, base layer |

| Power Mesh | 4-way stretch | Underarm panels |

| Warp-Knit Mesh | Durable, quick-dry | Outer vents, jackets |

| Spacer Mesh | Cushioning + airflow | Back panels, packs |

For technical specs and guidance, refer to Textile School’s Mesh Guide or check fabric performance categories on Performance Days.

Why Does GSM and Openness Matter?

Most lightweight technical meshes range from 60 to 140 GSM. Higher GSM means more strength, but less breathability. Openness ratio (the percentage of fabric that’s open vs. yarn) impacts airflow and heat dissipation. At Fumao, we supply 35% to 65% openness polyester hexagonal mesh and have it tested via CNAS-certified airflow resistance methods.

Explore textile airflow test methodology on SGS’s Performance Textile Services.

Where Are the Best Global Sources for Mesh Fabric?

If you're sourcing mesh fabric for outerwear, you need mills that offer consistency, scalability, and functional finishes. Location matters—not just for cost, but for compliance and delivery timelines.

Top sources for lightweight mesh include Keqiao (China), which leads in warp-knit mesh innovation; Taiwan, known for eco-functional yarns; and South Korea, recognized for premium high-stretch mesh production.

Why Is Keqiao a Top Choice for Mesh?

Keqiao is China’s largest textile cluster, producing 25% of global fabric exports. It offers:

- Warp-knit mesh under 200m MOQ.

- Custom dyeing within 7 days.

- Integration with coating, printing, or DWR treatment.

At Fumao Fabric, we deliver mesh fabrics with anti-pilling, moisture-wicking, and anti-bacterial finishes, validated by OEKO-TEX and GRS certifications. You can explore Keqiao factory operations via the Silk Road Keqiao official portal.

What About Taiwan and Korea?

Taiwanese mills offer high-quality polyester/spandex blends with seamless lamination or anti-odor finishes. Brands like Singtex or Tex-Ray export mesh to major outdoor brands in Europe and the US.

Korean suppliers specialize in nylon + PU breathable mesh, often used in military uniforms, bike jerseys, or helmets, with better colorfastness and dimensional stability. See technical sourcing examples via KOTRA Korea Trade Investment.

What Performance Specs Should You Require from Suppliers?

Choosing the right mesh is about more than just how it looks or feels. You need performance specs that align with how the outerwear will be used, washed, and worn. That’s where fabric testing and transparency matter.

Technical outerwear mesh should be tested for GSM, dimensional stability, colorfastness to sweat and UV, abrasion resistance, and air permeability. Key metrics help you predict long-term product integrity.

Which Test Standards Are Most Relevant?

- GSM (g/m²): Measured via ASTM D3776.

- Air Permeability: ASTM D737 or ISO 9237.

- Abrasion Resistance: Martindale (ISO 12947).

- Colorfastness: AATCC 16 (light), 15 (perspiration).

- Bursting Strength: ASTM D3786 for stretch mesh.

We offer test reports via SGS and Intertek, embedded with QR-code traceability per batch. For sourcing standard definitions, visit Textile Exchange Resources.

Can Suppliers Customize Specs?

Yes, especially in China. At Fumao, we help clients adjust GSM from 70 to 120, modify openness ratios, and add anti-odor silver ion finishes or carbon mesh blends. Custom printing (sublimation or transfer) on mesh is also available for branding. For advanced finishing methods, refer to Avery Dennison’s Performance Materials Guide.

How to Vet Mesh Fabric Suppliers for Long-Term Reliability?

Not all mesh suppliers are built the same. With so many claims in the market, you need a structured way to verify quality, consistency, and production ethics—before you place your bulk order.

The most reliable mesh suppliers provide testing documentation, offer small-batch sampling, maintain OEKO-TEX/BSCI/GRS certifications, and allow traceability of yarn origin and dyeing conditions.

What Documents Should You Request?

Always ask for:

- Material safety data sheets (MSDS)

- BSCI, OEKO-TEX, or GRS certifications

- Batch-specific lab reports

- Fabric spec sheets (PDF or physical)

Avoid vendors who only send “product photos” without test details. You can verify certification codes via OEKO-TEX’s Label Check or search suppliers on Alibaba Gold Verified.

Should You Visit or Audit the Factory?

Yes—if your order is >1,000 meters/month, factory visits or virtual audits are recommended. Our Fumao team offers:

- Real-time video walkthroughs

- Third-party QC inspection reports

- Shipment-ready sampling for pre-bulk validation

We also integrate with Bureau Veritas for bulk compliance inspections for our European and US clients sourcing technical mesh for licensed sportswear.

Conclusion

When sourcing lightweight mesh fabric for technical outerwear, the right supplier makes all the difference. You need mesh that breathes, stretches, and survives friction and weather, all while supporting comfort and design vision. That takes more than a Google search or supplier catalog—it takes data-backed sourcing and a fabric partner who understands how your outerwear performs in the real world.

At Fumao Fabric, we specialize in technical mesh solutions that meet global standards, support fast customization, and offer full pre- and post-shipment transparency. Whether you need polyester warp-knit mesh for cycling gear or nylon mesh lining for ski jackets, we’ve got the infrastructure, partners, and quality to deliver.

Want to source performance mesh with confidence? Contact our Business Director Elaine at elaine@fumaoclothing.com and let us support your outerwear development from yarn to shipment.