Pilling is the bane of knitwear—those fuzzy little balls that form on the surface of garments after a few washes can ruin even the most stylish design. For buyers, it's a top complaint; for brands, it can mean returns, poor reviews, and lost trust.

Compact yarn weaving, a method of spinning that produces cleaner, stronger yarns with fewer protruding fibers, is a proven solution for reducing pilling in knit fabrics. This technique enhances durability, smoothness, and overall garment quality—especially important in fashion categories like activewear, loungewear, and basics.

In this article, I’ll explain why compact yarn is a smart choice for pilling resistance, how it's made, where to source it, and which tests to demand from suppliers.

What Makes Compact Yarn Different from Regular Ring-Spun Yarn?

Traditional ring-spun yarn is made by twisting fibers together, but loose ends stick out from the surface. These stray fibers catch on friction and create pills. Compact spinning solves that by sucking in the fibers tightly before twisting.

Compact yarn has fewer flyaways, stronger twist integration, and a denser cross-section—reducing the root cause of pilling in knitted garments.

How Does Compact Spinning Work?

Compact spinning involves an additional drafting zone with suction that pulls stray fibers inward before final twisting. This process aligns the fibers better and removes air pockets. The result is a smoother yarn with less hairiness, which is the main factor in pilling formation. Learn more from Textile Learner.

At Fumao, we use compact ring frames with active suction heads. Our compact cotton yarns show 30–50% lower pilling than conventional ring-spun yarns under ICI test standards.

Why Is Compact Yarn Better for Knit Fabrics?

Knitted fabrics, unlike woven, stretch and rub more—especially in leggings, T-shirts, and sportswear. This makes them more prone to pilling. Using compact yarn helps the knit surface stay smooth over time. We recommend compact yarn for single jersey, rib, interlock, and ponte di Roma applications.

How Does Compact Yarn Improve Fabric Performance?

Compact yarn doesn't just reduce pilling—it improves multiple fabric properties that matter to consumers and retailers alike.

Fabrics made with compact yarn have higher tensile strength, better abrasion resistance, improved dye uniformity, and a cleaner appearance. These features extend garment life and elevate perceived value.

Does Compact Yarn Help in Activewear?

Yes, especially in blends like cotton-spandex or nylon-poly. For example, we produce compact combed cotton with 5% elastane for sports T-shirts. These fabrics undergo intense motion and friction—compact yarn helps prevent surface degradation. Brands like Under Armour and Uniqlo use similar technologies for anti-pilling.

Our clients have reported 40% fewer customer complaints related to pilling after switching to compact-yarn knits. Lab tests confirm resistance above level 4 on the Martindale pilling scale.

Is It Suitable for Dyed or Printed Fabrics?

Absolutely. Compact yarn's even surface allows better dye penetration and reduced blotchiness. We use reactive and disperse dyes on compact-based jerseys and fleece. In sublimation printing, compact yarn ensures crisp edge retention. See digital textile printing trends for use cases.

Where Can You Source Compact Yarn Knit Fabrics?

Not every mill offers compact yarn—weaving with it requires special frames, tight controls, and higher-grade fiber input. But growing demand from Europe and the US is expanding global supply chains.

China, India, and Turkey are leading compact yarn suppliers, with many Keqiao-based mills (including us at Fumao) offering knit fabrics made from compact cotton, modal, bamboo, and recycled blends.

What Are Typical MOQ and Lead Times?

Most compact yarn knits require MOQs of 300–500 meters per color for custom dyeing. We keep stock greige available in single jersey, interlock, and pique textures. Sample lead times range from 2–5 days for lab dips and 10 days for finished rolls. Our express logistics channel supports air consolidation shipping for fast delivery.

If you’re a small brand testing premium basics, we offer pre-finished rolls with low-MOQ colorways and swatch kits. We also support DTY and ring-spun compact yarn sourcing for those making their own fabrics.

Are Certifications Available?

Yes. Our compact yarn fabrics can meet OEKO-TEX® Standard 100, GRS (Global Recycled Standard), and REACH compliance. We provide full traceability reports, lab test data, and physical inspection records. Clients receive digital reports via shared Google Drive folders.

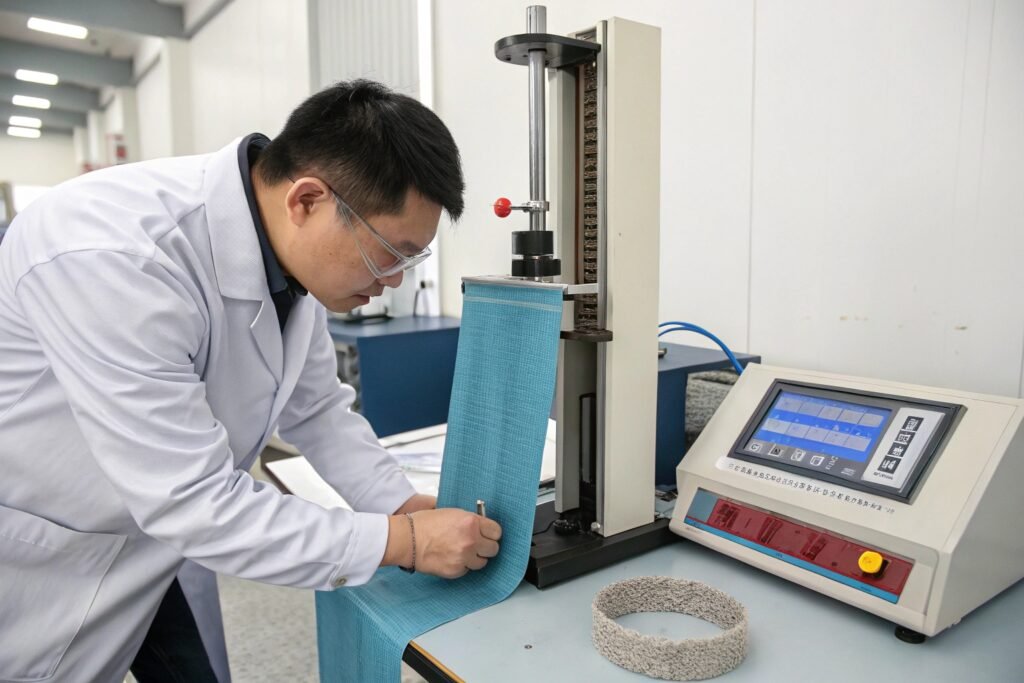

What Testing Should Be Done to Verify Pilling Resistance?

Claims mean nothing without data. Testing is critical to verify that your knit fabric really resists pilling under real-world use.

Request pilling test results (ASTM D3512 or ISO 12945-2), fabric surface scans, and abrasion resistance metrics before placing bulk orders. Look for scores of 4 or above to ensure high-performance output.

What Testing Methods Are Industry Standard?

The most common are:

- Martindale Pilling Test (ISO 12945-2): Simulates rubbing under tension.

- ICI Pilling Box (ASTM D3512): Uses cork lining to mimic washing-related pilling.

We also perform yarn hairiness testing (Uster Hairiness Index) and yarn strength verification. Reports are issued via SGS or ITS upon request.

How Do We Support Testing for Custom Projects?

At Fumao, we offer free lab testing on all compact yarn knit prototypes. Results are shared within 72 hours. For large projects, we offer a “lab-to-bulk” system, where shade, strength, and pilling specs are tracked across every roll using QR codes. This data helps buyers meet retailer compliance and reduce quality claims post-delivery.

Conclusion

Compact yarn weaving is one of the most reliable ways to fight pilling and elevate your knitwear quality. Whether you're designing for performance, fashion, or sustainability, choosing the right yarn structure ensures long-term customer satisfaction. At Fumao, we help buyers source certified compact yarn knits with low MOQs, fast sampling, and lab-backed quality. Don’t settle for scratchy, fuzzy fabrics—choose durability with design.