Pilling can ruin the perception of fabric quality in seconds—one glance at those annoying fuzz balls and a buyer may walk away. As a fabric manufacturer, I’ve seen even experienced importers confused by the numbers in lab reports. But when we talk about long-term performance and customer satisfaction, understanding pilling test results is not optional.

Evaluating pilling test reports correctly allows buyers to assess fabric durability, choose suitable applications, and avoid costly complaints and returns.

If you're sourcing from China and reviewing test reports from suppliers like us, understanding how to interpret pilling grades, test methods, and real-world implications gives you the upper hand. Let’s unpack this together—straight from the source.

What Do Pilling Grades Actually Mean?

When a fabric supplier presents a test report showing “Grade 4-5” for pilling, what does that really mean for your final product? These numbers follow industry-wide scales but interpreting them requires some context.

Pilling grades range from 1 (severe pilling) to 5 (no pilling), with most export-quality fabrics rated between 3.5 and 5 depending on end use.

What Testing Standards Are Commonly Used?

Most reports you receive will follow one of these globally recognized standards:

- ASTM D3512 (Random Tumble Pilling)

- ISO 12945-1 (Martindale Method)

- ISO 12945-2 (Pilling Box Method)

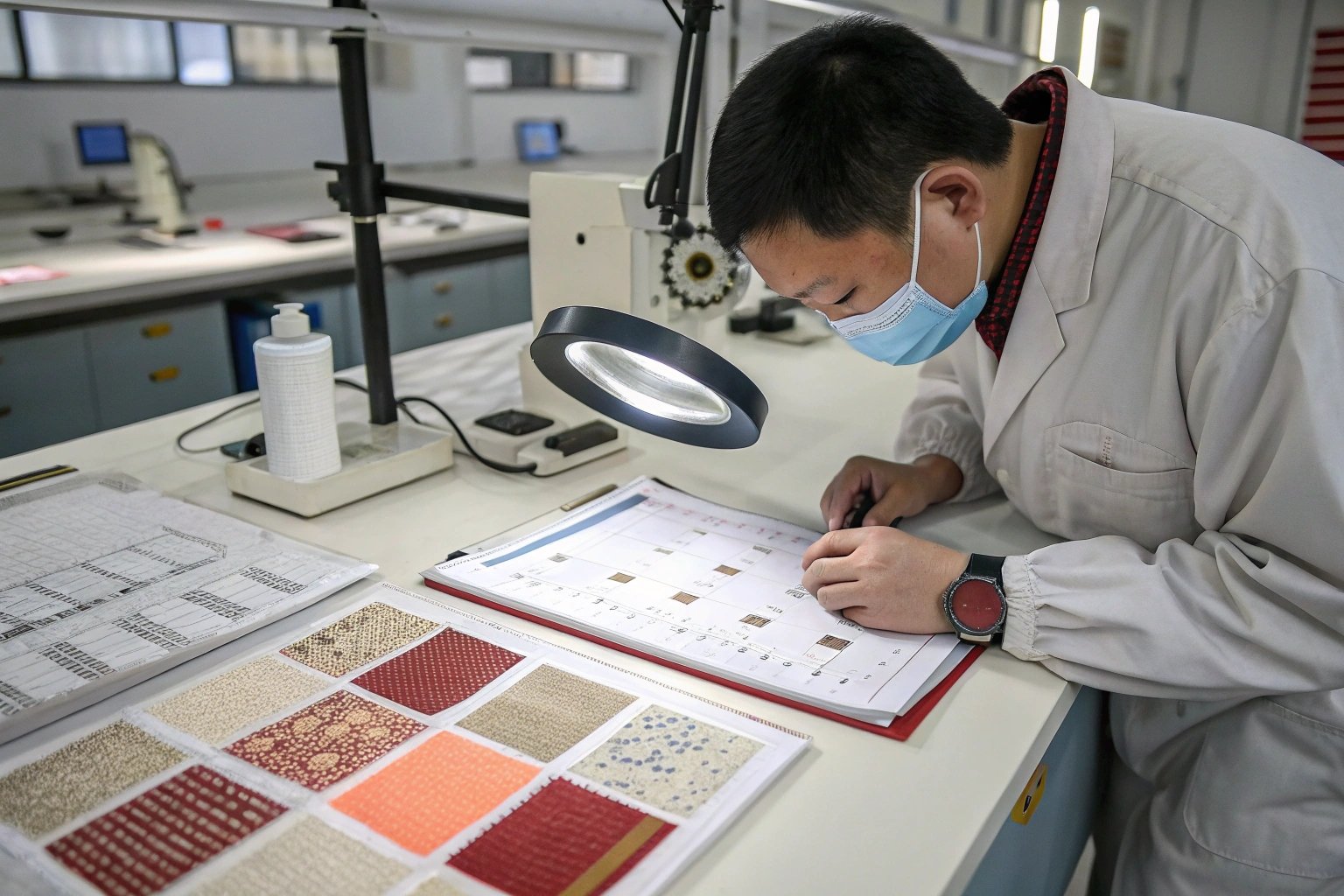

Our lab at Fumao Fabric uses CNAS-accredited procedures based on ISO 12945-2. The method simulates fabric rubbing over time and then grades pilling visually compared to control samples. Understanding the standard used helps you compare across suppliers fairly.

How Do You Read the Test Sheet Accurately?

A good test report should clearly show:

- Test method used

- Machine brand/model (e.g., James Heal)

- Fabric weight and composition

- Number of cycles (e.g., 500, 1000, 2000)

- Visual grade (from 1 to 5)

Suppliers who leave out any of these details might be hiding weak performance. Always ask for a full test sheet like the one you can find in SGS sample reports.

Which Fabrics Are More Prone to Pilling?

Not all fabrics pill the same. Pilling depends on fiber type, yarn twist, weave structure, and finishes. If you're buying polyester knits, expect some pilling unless specially treated.

Short staple fibers, loosely twisted yarns, and brushed finishes increase the risk of pilling, especially in synthetic blends.

Are Natural Fibers Better Than Synthetics?

Not necessarily. While natural fibers like cotton and wool may pill less, it depends on their treatment. For example, low-twist yarns used in soft brushed cotton flannels tend to pill more than compact spun yarns in synthetic activewear. The key lies in construction—not just the fiber.

We work with both compact cotton yarns and anti-pilling polyesters, and our testing shows that treated synthetics can outperform untreated naturals in durability.

What Are High-Risk Fabric Constructions?

Fabrics with the following characteristics are more likely to pill:

| Risk Factor | Examples |

|---|---|

| Loose weave/knit | Single jersey, terry, fleece |

| Soft finishes | Brushed cotton, peach finish |

| Short fibers | Recycled cotton, viscose |

| Low twist yarn | Sweater knits, flannels |

Before finalizing your order, request that suppliers confirm whether anti-pilling finishes were applied. At Fumao, we offer enzyme washing or silicon coating for smoother surfaces.

What Pilling Grade Should You Accept for Different Uses?

Not every fabric needs a Grade 5. Over-specifying may add cost without functional gain. It’s better to match grade requirements to the product’s end-use.

For casualwear, a grade of 3.5+ is often sufficient, while premium brands may request 4 or higher for customer retention.

How Do Brands Determine Acceptable Grades?

Here’s a practical framework many brands use:

| Fabric Use | Recommended Pilling Grade |

|---|---|

| Casual T-shirts | 3–3.5 |

| Children’s wear | 3.5–4 |

| Office shirts | 4–4.5 |

| High-end fashion | 4.5–5 |

| Upholstery fabrics | 5 |

Many of our clients in the US retail sector request 4+ for adult garments and 3.5+ for babywear. We recommend balancing between cost and performance. You don’t need overengineering for a fast fashion product.

Should You Accept a “Range” in Grades?

It’s common to see a range like “Grade 4–5.” That means some test samples showed near-perfect results, while others showed slight pilling. This is generally acceptable for woven cottons or blends. But for high-performance wear, aim for consistent Grade 5.

Always cross-check the stated grade against other tests (abrasion, colorfastness) for a more holistic view. You can also request pre-shipment inspection by third-party labs for confirmation.

How to Communicate Effectively with Suppliers About Pilling?

Many disputes over fabric quality stem from poor communication about test expectations. As a supplier, I appreciate when buyers ask detailed questions instead of vague requirements.

Clear communication about testing standards, acceptable grades, and visual references reduces misunderstandings and ensures better fabric outcomes.

What Questions Should You Ask Before Ordering?

When sourcing, try these questions:

- What pilling test method was used?

- What’s the target pilling grade for this order?

- Was the test conducted on the exact bulk fabric?

- Are anti-pilling treatments applied?

- Can I receive a sample from the tested batch?

Our clients who ask these questions upfront rarely run into post-shipment issues. It creates a standard and sets expectations.

Can You Request Third-Party Testing?

Absolutely. In fact, we encourage it for high-volume or first-time orders. We often work with labs like SGS and ITS to verify consistency. Many buyers also request a pre-shipment inspection that includes pilling re-tests and visual grading.

At Fumao, our internal lab also offers photo-verified results and video documentation, giving clients a transparent view of what to expect. Building that trust makes future orders smoother and faster.

Conclusion

Reading pilling test reports is like reading a map—it guides your decisions, sets quality expectations, and protects your brand. Whether you're sourcing basics or premium apparel, knowing what Grade 4 vs. 5 actually means helps you make smarter choices. In a world where one poor review can hurt your product line, don’t leave quality to guesswork. As a manufacturer with CNAS-certified facilities and international clients, I know firsthand how crucial accurate testing and clear reporting are. Always dig deeper, and don’t hesitate to ask your supplier the tough questions.