Blockchain is no longer just a buzzword in cryptocurrency—it’s revolutionizing industries that rely on transparency, speed, and traceability. As a textile manufacturer rooted in Keqiao, I’ve seen firsthand how fabric buyers today demand not just quality, but confidence. They want proof that what they ordered is what they receive, from the cotton field to the container ship.

Blockchain enhances fabric supply chain trust by creating a transparent, tamper-proof, and verifiable digital ledger across all stakeholders—from mills to fashion brands—offering end-to-end traceability, auditability, and faster dispute resolution.

At Fumao Fabric, we didn’t adopt blockchain because it was trendy. We did it because our buyers—whether large importers from Europe or fast-scaling fashion brands in the US—were tired of shipment errors, labeling inconsistencies, and vague fabric sourcing. They wanted proof and peace of mind. And blockchain gave us a way to deliver both.

What problems does blockchain solve in textile sourcing?

When fabric shipments go wrong—be it mislabeling, late delivery, or poor quality—trust breaks down fast. Buyers often have no way to trace what went wrong, or who’s accountable.

Blockchain technology solves key pain points in textile sourcing by delivering a decentralized, transparent record of every transaction and transformation along the supply chain.

How does blockchain prevent fabric mislabeling and fraud?

Fabric mislabeling is a common industry issue. A roll tagged as “organic cotton” may turn out to be blended. Buyers have historically depended on lab tests or blind trust. Blockchain eliminates this guesswork. Each stage—from yarn spinning to dyeing—logs immutable entries into the chain. Labels are digitally verified, not handwritten.

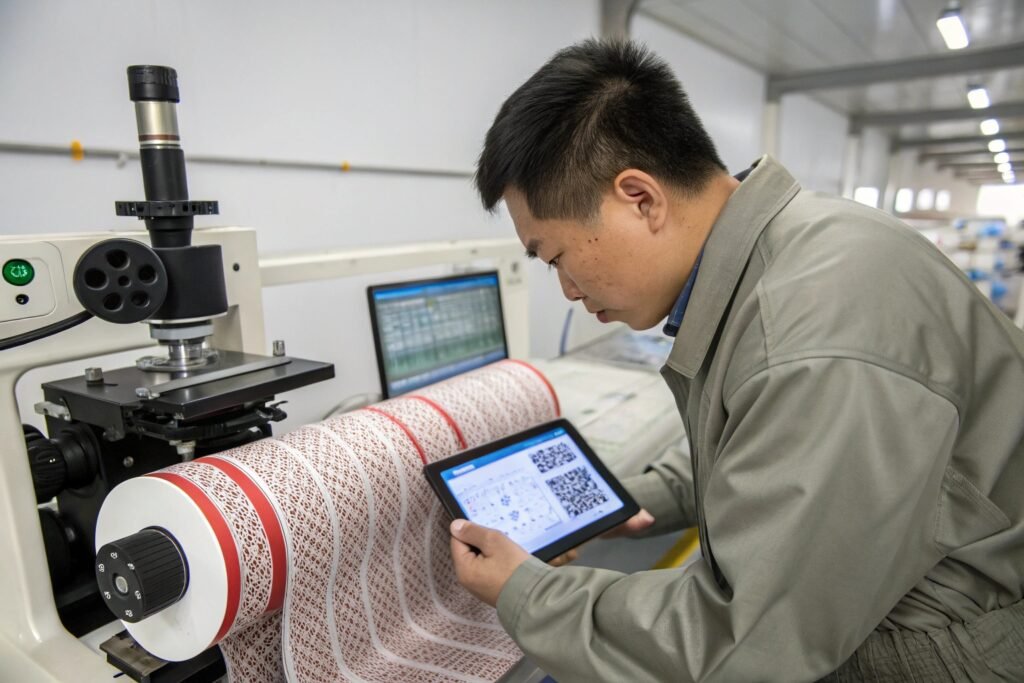

For example, we log QR codes at the weaving stage in Keqiao. These codes are scanned again at the dyeing house, printing facility, and inspection. This lets our American clients verify the process integrity from their laptops.

Can blockchain help trace ethical sourcing and sustainability claims?

Yes—and this is where blockchain shines. Buyers increasingly demand sustainability. But how do they verify a roll of recycled PET chiffon really came from certified waste?

Through blockchain, we connect certificates like GRS, OEKO-TEX, and CNAS lab tests directly to digital batches. Every buyer can see the factory name, fabric batch, and certifying body in one dashboard. For example, a U.S. startup sourcing our Tencel-blend satin now uses blockchain logs to showcase sustainability to their investors and customers via traceable QR codes.

How does blockchain support secure international payments?

Fabric buyers often face delays and confusion when paying suppliers abroad. Traditional methods—like wire transfers—are slow, opaque, and open to fraud.

Blockchain enables faster, safer international payments using smart contracts, reducing disputes and delays in fabric orders.

What are smart contracts and how do they work in textiles?

A smart contract is a self-executing agreement written in blockchain code. Once pre-agreed conditions are met—say, 10,000 meters of printed linen delivered—payment is released automatically.

This removes manual intervention, especially when we work with Alibaba partners or U.S. importers who use L/C. We've even piloted Ethereum-based smart contracts for express textile sampling orders under $5,000.

How do blockchain wallets reduce foreign currency risk?

Currency fluctuation and cross-border transaction fees eat into margins. With stablecoins like USDC or DAI, buyers can hold value in a blockchain wallet, pegged to USD. This eliminates surprises when paying for bulk orders or development fees.

We integrate this with our digital quoting system, showing customers real-time fabric costs, freight, and taxes. It builds the same level of trust you’d expect from global fintech firms.

How does blockchain improve fabric quality tracking?

Fabric quality is not just visual—it’s technical. Most disputes in B2B textile trade stem from unclear standards or unverifiable results.

Blockchain logs test results, defect reports, and approval stages on-chain, improving quality tracking and accountability in textile exports.

Can blockchain track real-time QC results?

Yes. We embed CNAS lab test results directly onto blockchain ledgers. Buyers can scan a roll and immediately see test values for GSM, shrinkage, pH, and lightfastness. This real-time quality data empowers U.S. and European customers to make faster decisions or trigger rechecks before shipments.

How does it streamline production approvals?

Sometimes the delay is not fabric production—but communication. A sample is sent, approved, forgotten, or miscommunicated. Blockchain stores time-stamped feedback, lab dips, and approval status per batch. This eliminates email threads and misfiled Excel sheets.

We’ve also developed blockchain-linked dashboards for certain fast-fashion buyers to approve up to 30 sample swatches in one click, with lab results embedded and visible through encrypted portals.

Why is blockchain crucial for customs and freight?

Fabric exports are data-heavy—packing lists, invoices, certificates, freight documents. Mistakes or delays at customs can mean lost sales or penalties.

Blockchain simplifies freight documentation and customs compliance by offering verifiable digital paperwork and smart logistics contracts.

How does blockchain speed up customs clearance?

Digital manifests linked to blockchain cut verification time. Instead of emailing PDFs or printing folders, we link shipping details, inspection reports, and origin certificates to a verifiable blockchain chain. This lets customs in the U.S., Europe, or Russia verify shipments instantly.

For high-volume clients, we integrate this into their ERP to auto-match fabric POs with shipping data, cutting customs wait time by up to 40%.

Can blockchain reduce logistics disputes?

Yes. Smart contracts in logistics auto-trigger status updates from fabric packaging to port arrival. If a shipment is delayed, the buyer sees it. If a carton is missing, the chain shows where it was last scanned. This transparency has helped us cut shipping disputes by 60%, and even boosted buyer retention, especially among 3PL-savvy brands.

Conclusion

Blockchain isn’t just a technology—it’s a new way to build trust. For fabric buyers navigating complex orders, overseas factories, and tight timelines, it offers clarity where there was once chaos. At Fumao Fabric, we’ve made blockchain part of our DNA—from sampling to shipping. And in doing so, we’ve earned the trust of hundreds of global partners who now see not just textiles—but truth—woven into every meter we ship.