Many buyers struggle with outdoor or high-use fabric fading after just a few months. Whether it’s fashionwear exposed to sun, car interiors, or marine upholstery, faded colors quickly damage product appeal and brand reputation. Frequent replacements drive up costs, and buyers lose confidence.

Solution-dyed fabrics offer superior fade resistance because color is locked into the fiber itself before it’s even spun into yarn. Compared to traditional dyeing, solution-dyeing delivers long-lasting vibrancy—even under intense UV exposure, repeated washing, or heavy outdoor use.

This article explains how solution-dyed fabrics work, why they outperform piece-dyed alternatives, and how sourcing them from China can reduce both fading and costs.

How Does Solution Dyeing Work Differently?

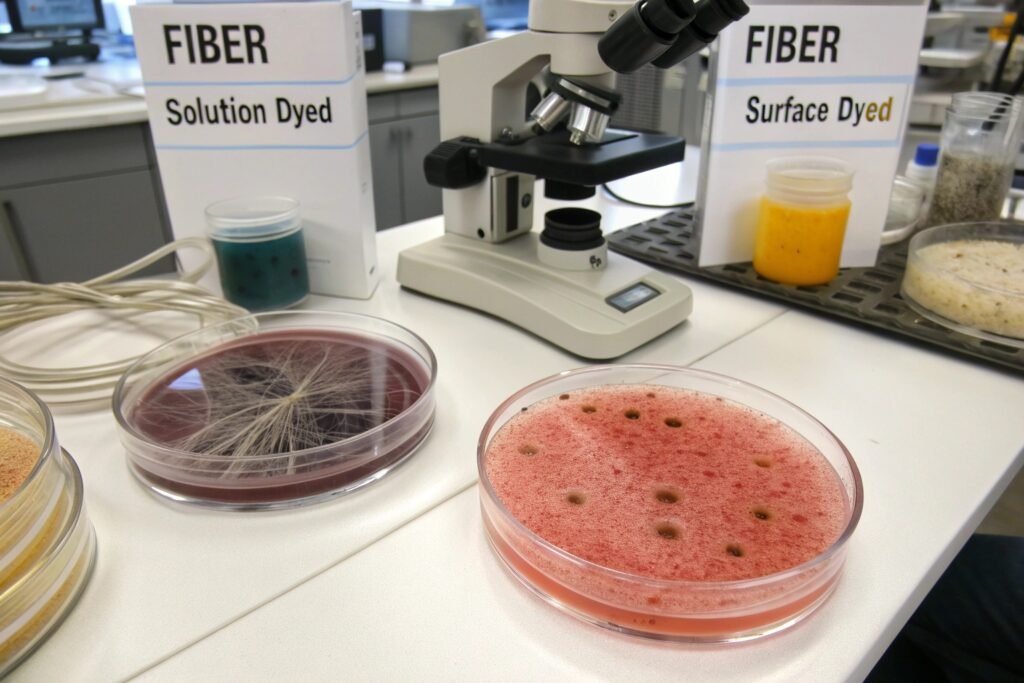

When it comes to achieving durable color, the process of how a fabric is dyed makes all the difference. Traditional dyeing methods apply color to the outer surface of a finished fabric. In contrast, solution dyeing infuses color into the polymer solution before the fiber is even formed.

In solution dyeing, color becomes part of the fiber itself—resulting in unmatched fade resistance, better colorfastness, and longer product life.

What’s the Technical Advantage of Solution Dyeing?

The color in solution-dyed fibers is evenly distributed throughout the entire cross-section. This means even if the surface gets abraded, the color remains consistent. Unlike piece-dyed fabrics, where UV or washing can strip or fade surface pigments, solution-dyed fibers maintain full saturation for years.

This method is especially useful for synthetic fibers like polyester, acrylic, and olefin. These are common in outdoor textiles, automotive fabrics, and uniforms—products that must withstand harsh sunlight or repeated washing.

Does It Affect the Feel or Flexibility?

No. Modern techniques allow solution-dyed fabrics to be just as soft and flexible as regular dyed fabrics. At our Fumao facility, we integrate the solution dyeing stage directly with the extrusion of synthetic fibers, ensuring consistent quality and performance without compromising drape or hand-feel.

What Industries Benefit Most from Solution-Dyed Fabric?

If your products are exposed to sun, moisture, or repeated cleaning, then solution-dyed textiles are the gold standard. They combine visual appeal with rugged durability.

Industries that benefit most include outdoor furniture, uniforms, transportation upholstery, marine gear, and children’s products—all of which demand color longevity.

Why Are Outdoor Products the Top Application?

Outdoor furniture and accessories are directly exposed to UV radiation and rain. Brands like Sunbrella popularized solution-dyed acrylic fabrics in cushions and awnings due to their unmatched fade resistance. At Fumao, we offer comparable alternatives using solution-dyed polyester at lower prices, serving global retailers and outdoor furniture OEMs.

Unlike traditional dyes that leach or bleed, our solution-dyed fabrics retain bold colors for up to 5 years in extreme outdoor use. They're also mold and mildew-resistant, further enhancing outdoor performance.

How Do Uniforms and Interiors Benefit?

Transportation seating—like buses, trains, and planes—needs fade resistance due to continuous use and cleaning. Similarly, uniforms for schools, medical, or hospitality sectors must withstand repeated industrial washing. Many of our clients in the contract textiles sector choose solution-dyed polyesters for this very reason.

How Do Solution-Dyed Fabrics Help Reduce Maintenance?

One of the biggest hidden costs for textile products is maintenance. Fading often leads to early replacement. Dirt and cleaning can accelerate wear, especially in dyed textiles where chemicals strip surface color.

Solution-dyed fabrics are easier to clean and maintain since their color won't fade with abrasion, UV, or bleach exposure—leading to fewer replacements and longer product lifespans.

Are They Stain-Resistant?

Yes. While not all solution-dyed fabrics are waterproof, they are generally more stain-resistant than traditional fabrics. At Fumao, we apply additional finishes like Teflon™ coating or PU lamination for customers needing outdoor or medical use. These treatments work synergistically with solution-dyeing for stain protection.

For example, a major hospital textile supplier we work with reported a 35% drop in fabric changeover costs after switching to solution-dyed hospital gowns due to bleach wash tolerance.

Can They Be Machine Washed Repeatedly?

Absolutely. The color doesn’t bleed, so there’s no cross-staining in mixed laundry loads. In fact, these fabrics hold up even under industrial laundering. They’re bleach-safe and retain vibrancy after hundreds of washes, ideal for uniforms, daycare bedding, and commercial interiors.

How to Source Affordable Solution-Dyed Fabrics from China?

Despite the high-tech nature of solution dyeing, prices have dropped significantly in recent years due to scale and innovation—especially in China.

To source affordably, buyers should look for manufacturers with in-house fiber extrusion and dyeing lines, long-term export experience, and sampling capabilities for low MOQs.

Which Chinese Regions Specialize in This?

Keqiao, Zhejiang is a powerhouse for synthetic fabric manufacturing. Our Fumao factory there integrates dyeing and spinning—removing the need for third-party color houses. This allows us to offer rapid color lab dips, fast sampling (within 48 hours), and consistent quality from fiber to finish.

You can verify certifications like Oeko-Tex® and CNAS compliance through our QR-based fabric traceability system—ensuring buyers that colors are safe, permanent, and sustainably developed. Learn more about textile eco-labels before placing large orders.

Is There a Minimum Order for Custom Colors?

Most factories will ask for 1000 yards per color, but we offer lower MOQs for certain shades already in stock. We recommend reaching out via our inquiry page with your desired Pantone code or reference fabric. Our team will respond within 24 hours and offer digital swatches or physical samples.

Conclusion

Solution-dyed fabrics aren’t just a technical upgrade—they’re a smart investment. Whether you're designing outdoor gear, uniforms, or commercial interiors, choosing this method reduces maintenance, increases color longevity, and boosts customer satisfaction. At Fumao, we combine solution dyeing with affordable pricing, fast development, and international-grade quality. If fade resistance matters to your market, then this is the fabric innovation worth embracing.