Global fashion brands and conscious buyers are increasingly turning to deadstock fabrics—unused textile rolls from overproduction or canceled orders—as a way to cut waste and costs. But in China, where production volume is high and access can be opaque, sourcing these materials ethically poses both opportunity and risk.

This article explains how to ethically source deadstock fabrics from Chinese suppliers, including where to find them, how to verify authenticity, what certifications matter, and how to avoid greenwashing traps.

If you’re a startup designer, procurement officer, or sustainable sourcing agent, this guide will help you reduce environmental impact and find real value in China’s massive textile inventory.

Where Can You Find Reliable Deadstock Suppliers?

Ethical sourcing starts with trustworthy partnerships. In China, deadstock fabric is widely available—but only certain channels offer verified quality and sustainable handling.

The best sources for deadstock include verified suppliers at Keqiao Textile Market, Alibaba Gold Suppliers with clear surplus declarations, and manufacturers with export compliance transparency.

Can You Trust Keqiao Market Suppliers?

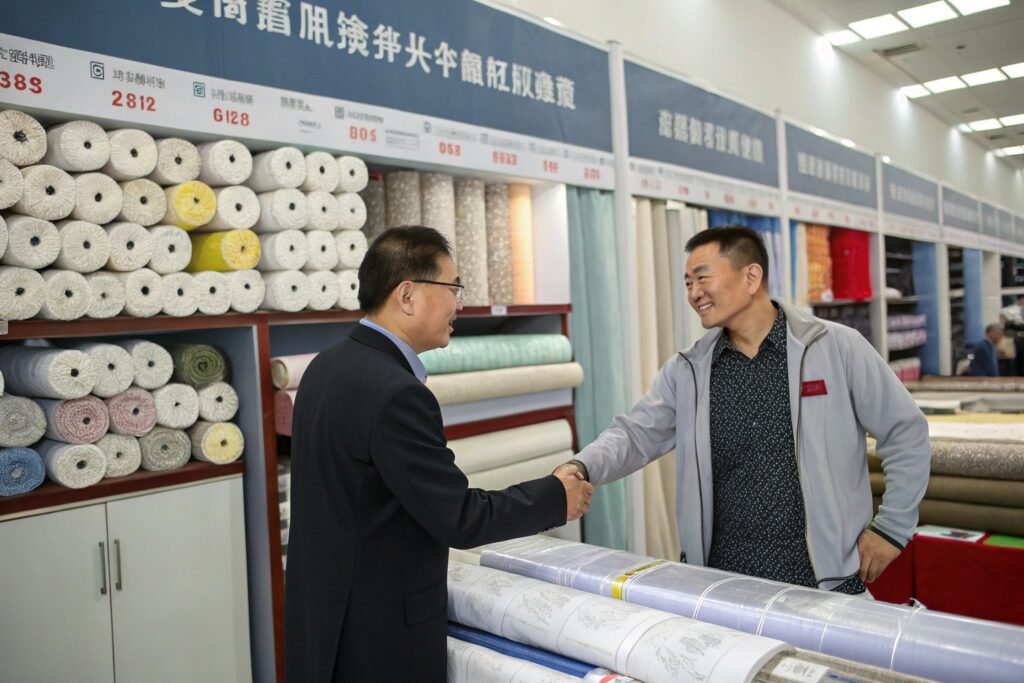

Keqiao, home to the largest fabric market in the world, is a hotspot for surplus and leftover stock. Many small traders here handle cancelled orders from export factories. While options are abundant, buyers must inspect labeling integrity, roll condition, and storage practices.

Working with suppliers based in Keqiao’s bonded zones also gives access to export-declared surplus—making it easier to trace fabric origin and legality.

Are Online Platforms Like Alibaba Reliable for Deadstock?

Some vetted Alibaba sellers now offer deadstock under “surplus inventory” categories. Look for those with video walkthroughs, transparent stock photos, and confirmed export histories.

However, ethical sourcing on these platforms requires extra scrutiny—such as requesting inspection reports or even virtual video audits to confirm deadstock status.

What Makes Deadstock Truly Ethical?

Not all surplus fabric is truly sustainable. Some are mislabeled, defective, or stored unsafely. To be ethical, deadstock must be unused, clean, properly stored, and not from exploitative labor systems.

Ethical deadstock is verified through clean origin, proper labeling, and alignment with international sustainability standards such as GRS or OEKO-TEX.

What Certifications Should You Look For?

While deadstock may not always carry full chain-of-custody certifications, many mills provide partial compliance, like:

- OEKO-TEX® Standard 100

- GRS (Global Recycled Standard)

- Internal test reports confirming no harmful chemicals (e.g., azo dyes)

Factories aligned with these programs often manage surplus under controlled conditions, making traceability possible even for leftovers.

How to Avoid Greenwashing?

Ethical claims can be misleading. Some suppliers may label ordinary overstock or even rejected fabric as “deadstock.” Request:

- Timestamped stock lists

- Video/photo records of warehouse conditions

- Third-party QC or SGS/ITS test reports

Transparency is key. Ethical sourcing relies more on evidence than labels.

How Can Small Buyers Access Deadstock?

Many believe deadstock is reserved for big brands. But in today’s digital era, even small buyers can tap into surplus materials—if they approach the right channels.

Small buyers can access deadstock through fabric agents, sample showrooms, B2B online platforms, or co-buying groups that split minimums.

What MOQ Should You Expect?

Deadstock fabrics are often in fixed quantities—like 200 to 2000 meters per color. But at Keqiao digital hubs, agents allow splitting lots or bundling colors for mixed orders.

Apps like FABSCRAP and WeChat groups run by sourcing intermediaries now share daily stock updates, ideal for capsule collections or test runs.

How to Handle Logistics for Small Quantities?

For small-volume buyers, shipping deadstock rolls via LCL sea freight or even express courier works. Some sellers offer packaging with QR inventory labels for easier customs clearance.

We support bundling different deadstock SKUs into one shipment, using our in-house packaging team and DDP logistics to reduce cost uncertainty.

What Are the Best Practices for Ethical Sourcing?

Beyond price and availability, true ethical sourcing involves a consistent decision-making framework, supplier vetting, and lifecycle awareness.

Best practices include pre-screening suppliers, demanding documentation, testing materials, and confirming worker welfare standards.

How to Build a Transparent Supplier Relationship?

Start with long-term communication—ideally in their preferred language (or with a bilingual agent). Ask direct questions about:

- Fabric origin and factory location

- Handling/storage process of surplus

- Their views on waste management

Tools like Sedex or BSCI audits can further assess human rights alignment.

Should You Combine Deadstock with Other Fabrics?

Yes, combining deadstock with made-to-order eco-textiles (like Tencel™ or recycled polyester) creates hybrid collections that scale. We often help brands match limited deadstock stock with repeatable eco-batch bases to ensure continuity and reduce waste.

Mixing allows both agility and accountability.

Conclusion

Deadstock fabrics present a smart, sustainable way to lower environmental impact and sourcing cost. But ethical deadstock sourcing from China requires more than just finding rolls—it demands traceability, supplier trust, and proper handling. As a fabric manufacturer with access to verified surplus and in-house QC, we help brands navigate this complex landscape. Whether you’re launching a capsule line or scaling sustainable SKUs, we’re ready to support your ethical sourcing journey.