When building a clothing line, you quickly realize that fabric costs add up fast—especially for large volumes. But one material seems to balance price, performance, and availability better than most: poly-cotton.

Blended fabrics like poly-cotton are popular not just because they’re cheaper—but because they reduce waste, resist wrinkles, and support global scalability.

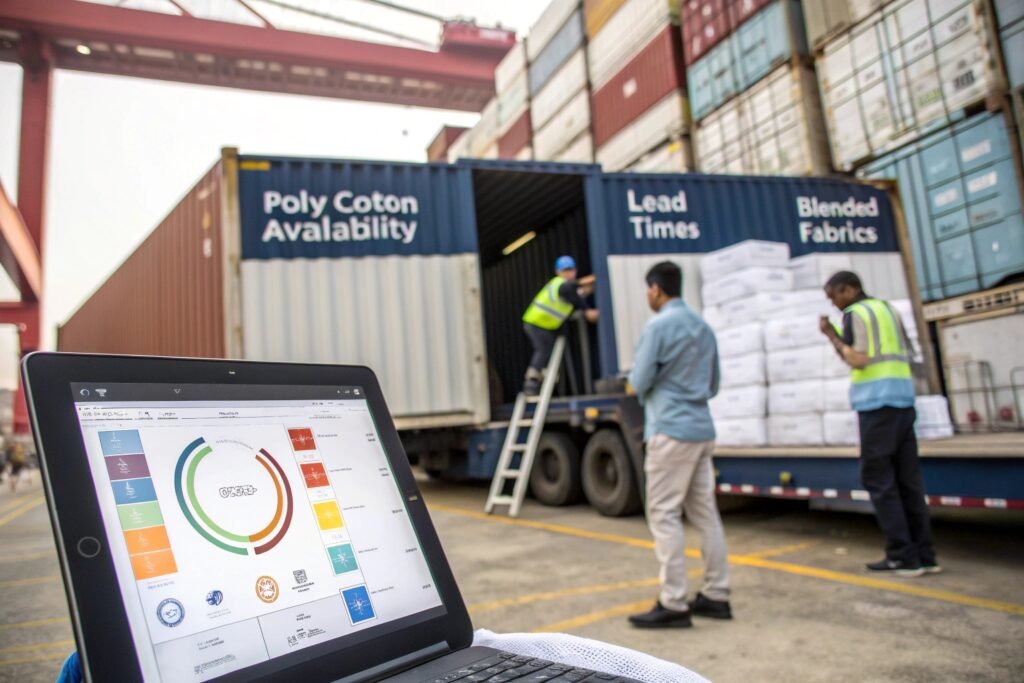

At Fumao Fabric, we supply millions of meters of poly-cotton to international brands seeking reliable, affordable options for t-shirts, uniforms, children’s wear, and fashion basics. Let me break down exactly why poly-cotton and other blends are so cost-effective—and how to source them wisely.

What Is Poly-Cotton and How Is It Made?

Poly-cotton is a hybrid material that combines natural cotton fibers with synthetic polyester filaments, spun together to form a single yarn. The result? A textile that’s both breathable and strong.

Most poly-cotton blends range between 50/50 and 65/35 (poly/cotton), though variations like 80/20 exist for performance-focused garments.

How Is the Blending Process Done?

Blending happens at the yarn stage. Raw cotton is cleaned and carded, then blended with melted polyester filaments. These are twisted together into yarn and woven or knitted as usual. The blend ratio determines final texture, drape, and feel.

Read about fiber blending techniques or see spinning processes from a textile education site.

What Are the Common Applications?

- T-shirts and polos

- School uniforms

- Workwear

- Bedsheets and pillowcases

Blends are chosen for their performance-price balance. At Fumao, 65/35 is our most popular blend for global buyers needing both durability and softness.

Why Is Poly-Cotton Cheaper Than 100% Cotton?

Raw cotton prices fluctuate with global crop yields, but polyester remains more price-stable. Blending the two lowers cost per meter and minimizes production loss due to shrinkage or dye failure.

Poly-cotton offers a predictable, affordable alternative to 100% cotton—especially when cotton prices spike.

What Are the Cost Benefits?

| Fabric Type | Avg. Price (USD/meter) | Shrinkage Rate | Dye Yield |

|---|---|---|---|

| 100% Cotton | $2.40 – $3.20 | High (3–5%) | Moderate |

| 65/35 Poly-Cotton | $1.80 – $2.20 | Low (1–2%) | Strong |

Source: Based on Textile Exchange fiber benchmarks and Fumao bulk order pricing.

How Does Polyester Reduce Costs?

Polyester is cheaper to produce and doesn’t absorb water like cotton, reducing dye costs and processing time. Poly-cotton blends also need less ironing and last longer in wash cycles, minimizing product returns.

Learn more from OECD fabric cost reports or view live pricing charts at Cotlook Index.

How Do Blends Improve Supply Chain Efficiency?

Blended fabrics are often more scalable than pure fibers. With fewer rejections in QC and better production yield, brands can move faster from sampling to delivery.

Poly-cotton’s durability, dye affinity, and global availability make it easier to manage high-volume sourcing.

What Are Lead Times for Blends?

In our Keqiao facility, standard turnaround times are:

- Stock poly-cotton: 5–7 days

- Custom dyed 65/35: 12–15 days

- Printed poly-cotton: 15–20 days

Compare that to sourcing organic cotton or special fibers like modal, which may take 25–45 days. See real lead time benchmarks at WTiN’s market data or Fibre2Fashion sourcing insights.

How Does QC Benefit from Blends?

Because poly-cotton is more stable dimensionally, there’s lower risk of shrinkage issues. Our lab testing at Fumao shows pass rates above 98% for blended orders, saving clients money on reprocessing or shipment delays.

What Are the Functional Advantages of Blended Fabrics?

Blended fabrics aren’t just cheaper—they’re smarter. Poly-cotton outperforms pure cotton in durability, wrinkle resistance, moisture control, and abrasion resistance.

That’s why it’s trusted in school uniforms, factory uniforms, hospital wear, and affordable fashion lines.

How Do Poly-Cotton Blends Perform in Real Use?

- Wrinkle Resistance: Holds shape better after wash

- Moisture Management: Cotton absorbs sweat, polyester dries it

- Strength: Higher tensile resistance than 100% cotton

- Fade Resistance: Polyester holds color better over time

See detailed comparisons on Sewport’s fabric performance charts or performance lab results from AATCC.

What Fabrics Are Commonly Blended with Cotton?

Besides polyester, brands also blend:

- Spandex: for stretch (e.g., 95/5 cotton-spandex)

- Viscose: for silky drape

- Modal: for softness

- Acrylic: for warmth

Each blend serves a specific market purpose. At Fumao, we offer over 50+ cotton-blend constructions, supporting MOQ as low as 300m for new designs.

Conclusion

Blended fabrics like poly-cotton offer the best of both worlds: the softness and breathability of cotton with the durability and price efficiency of polyester. They’re not only cost-effective but supply chain-friendly, performance-enhancing, and globally scalable. If you’re looking to build a fabric program that delivers both margin and quality, poly-cotton should be your go-to. At Fumao, we’ve helped hundreds of clients reduce their fabric costs without compromising garment appeal—through the strategic use of smart, reliable blends.