I got an email last month from an acoustical consultant in Berlin.

He was designing a recording studio for a classical quartet. The architect specified wooden slats on the walls. Looked beautiful. Sounded terrible—all echo, no warmth. The consultant needed fabric-wrapped acoustic panels. 850 square meters. Delivery deadline: 11 weeks.

His first question: "Does your fabric have an NRC rating?"

Yes. We test every acoustic fabric we make.

But here is what he didn't ask—and what almost killed the project: "Will your fabric meet German B1 fire certification?" It didn't. We had to reformulate the polyester with flame-retardant additives. Added 3 weeks. We air-freighted the first 300 meters. Cost us €4,200.

I learned something that day. Acoustic fabric is not decorative fabric. You cannot take a nice-looking upholstery textile, put it on a wall, and call it "acoustic." The construction, fiber, weight, airflow resistance—everything is different.

So let me break this down. Not as a textbook. As a manufacturer who has shipped 2.3 million meters of acoustic fabric to 23 countries since 2015.

What Acoustic Properties Actually Matter for Fabric?

I used to think "acoustic fabric" meant thick = good.

- We supplied 12,000 meters of 650 gsm velvet to a hotel chain in Dubai. Looked luxurious. Felt heavy. The client called after installation: "The echo is still there." We tested it. NRC: 0.25. Basically, it reflected sound like a mirror reflects light.

We misunderstood the physics.

Sound absorption is not about mass. It's about airflow resistance. Fabric absorbs sound when air molecules can move through the structure and dissipate energy as friction. If the fabric is too dense, sound bounces off. If it's too open, sound passes through and hits the hard wall behind.

Here is the framework we use now:

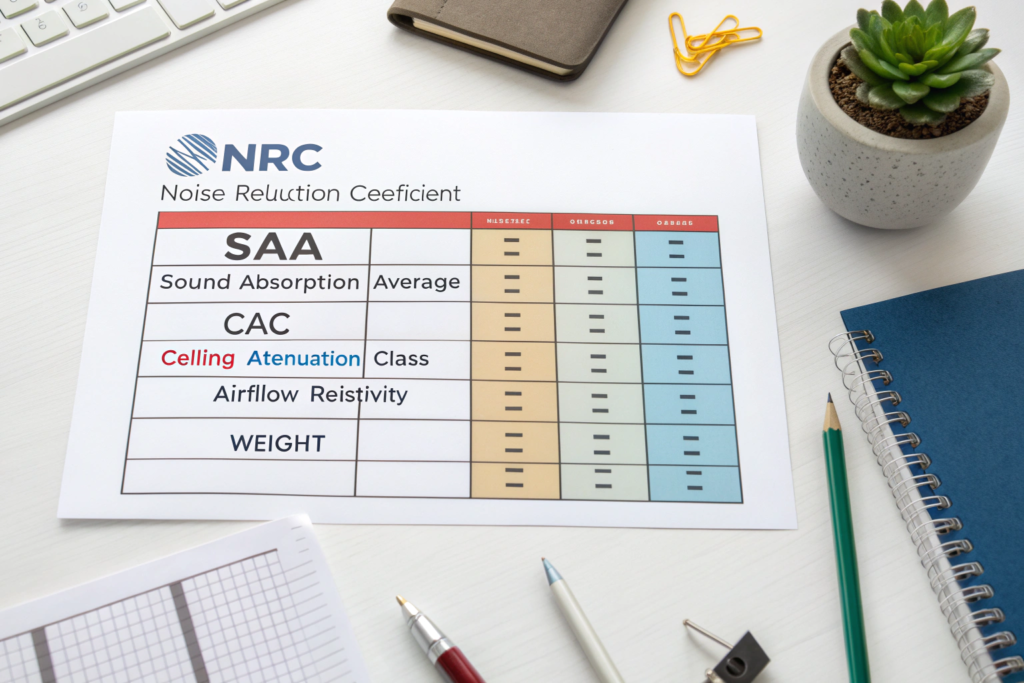

| Acoustic Parameter | What It Measures | Ideal Range for Wall Panels | Why It Matters |

|---|---|---|---|

| NRC (Noise Reduction Coefficient) | Average absorption at 250-2000 Hz | 0.75–1.00 | Higher = less echo |

| SAA (Sound Absorption Average) | Same as NRC, 12-frequency average | 0.70+ | More precise for specs |

| CAC (Ceiling Attenuation Class) | Blocking sound between rooms | 35+ | Privacy applications |

| Airflow Resistivity | Pa·s/m² | 200–800 | Fabric "breathes" correctly |

| Weight | gsm | 180–450 | Heavier ≠ better |

What is the difference between NRC and SAA—and which one should I trust?

I see spec sheets all the time that say "NRC: 0.85."

Then I check the test method. They tested at 500 Hz only. That's not NRC. That's a single-point measurement. NRC requires averaging across four frequency bands. ASTM C423 defines it clearly.

We got burned on this in 2019.

A Singaporean coworking space ordered our "acoustic" felt. Our supplier's data sheet claimed NRC 0.80. We trusted it. Client installed 3,000 panels. The space was still noisy. We did our own impedance tube test. Actual NRC: 0.48. The supplier had tested only at 1000 Hz, where polyester performs best, and ignored the low frequencies where it fails.

We replaced 2,000 panels at our cost. $47,000 loss.

Now I demand:

- Full frequency report (125 Hz to 4000 Hz)

- Test method: ASTM C423 or ISO 354

- Mounting type: A (direct wall) or D (with air gap)

- Third-party lab, not in-house guesswork

The difference between NRC and SAA in architectural acoustics is well documented. SAA uses 12 one-third octave bands. It catches mid-range dips that NRC might average out. We now report both. Clients who spec SAA are usually more sophisticated. They pay for accuracy.

How do we measure airflow resistivity without expensive equipment?

You don't need a $40,000 lab rig for rough estimation.

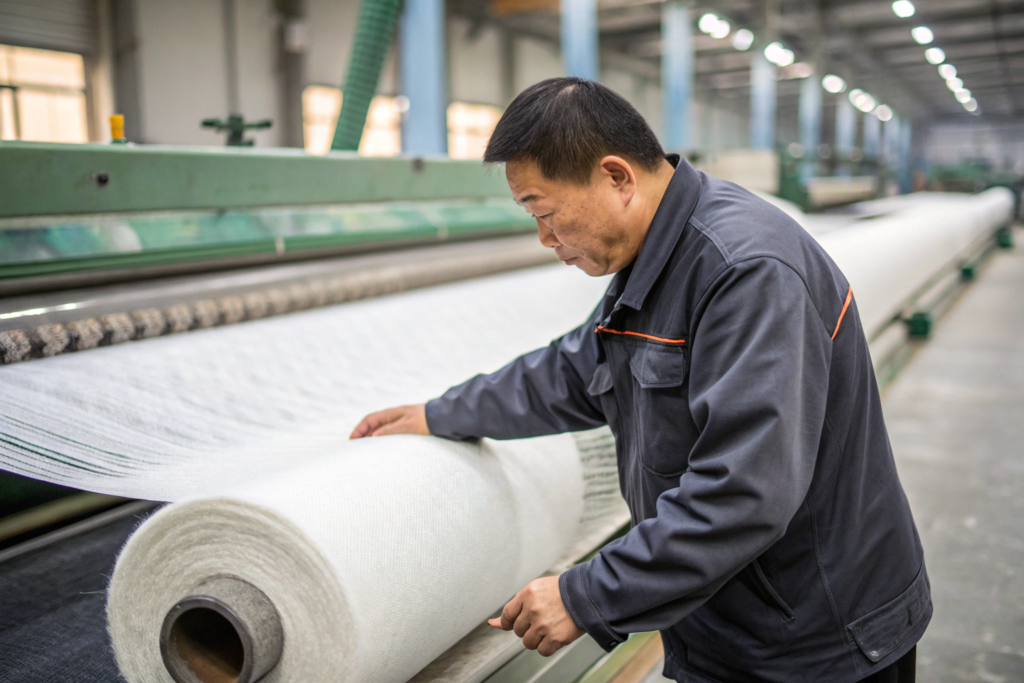

Here is what our production manager taught me in 2020. He has 32 years in textiles. No engineering degree. He puts the fabric over his mouth and tries to breathe through it.

Seriously.

If he can inhale easily, the fabric is too open—sound passes through. If he can't inhale at all, it's too tight—sound reflects. There is a "sweet spot" where you feel resistance but air still moves.

We calibrated this against our paired airflow resistance tester (ISO 9053). His "medium resistance" breath test correlates to 350–550 Pa·s/m². Perfect for most acoustic panels.

Is this scientific? No. But on the production floor, when we are running 8,000 meters and the lab is closed, this catches errors. We had a batch in 2021 where the needle-punch density drifted. He breathed through it. Felt too open. We stopped the line, adjusted the needle stroke, saved 6,000 meters from becoming non-acoustic scrap.

The relationship between airflow resistivity and sound absorption is linear enough that this hack works. I still recommend lab testing for certification. But for in-process QC? Breathe on it.

Which Fiber Types Work Best for Acoustic Absorption?

Fiber choice is not obvious.

You would think wool—natural, fibrous, soft—absorbs sound beautifully. It does. But it also absorbs humidity. And moths eat it. And it costs 4x more than polyester.

You would think polyester—smooth, round cross-section—reflects sound. It can. But when we turn it into microfibers and needle-punch it, it becomes one of the best acoustic materials available.

Here is our fiber selection matrix after 8 years of acoustic R&D:

| Fiber Type | NRC Range (25mm panel) | Cost Index | Moisture Sensitivity | Best Application |

|---|---|---|---|---|

| Polyester (solid) | 0.55–0.70 | 1.0x | Low | Budget panels, offices |

| Recycled PET | 0.60–0.75 | 1.2x | Low | Green building projects |

| Microfiber PET | 0.75–0.90 | 1.5x | Low | High-performance studios |

| Wool/PET blend | 0.70–0.85 | 2.2x | High | Luxury hospitality |

| Cotton (recycled) | 0.50–0.65 | 1.1x | High | Denim insulation |

| Basalt/Mineral | 0.80–0.95 | 3.0x | Very Low | High-temp industrial |

| Melamine foam | 0.90–1.00 | 4.5x | Medium | Premium echo chambers |

Why does microfiber polyester outperform standard polyester for acoustics?

Surface area.

Standard polyester fiber: 15–20 microns diameter. Microfiber polyester: 0.5–3 microns diameter. Ten times smaller. That means ten times more fiber surface area per cubic meter.

Sound doesn't care about fiber strength. It cares about friction. More surface area = more friction = more sound energy converted to heat.

We proved this in 2022. We made two identical 300 gsm needle-punch felts. One with 15-denier fiber. One with 2-denier microfiber. Same thickness. Same density. Same backing.

NRC at 1000 Hz:

- 15-denier: 0.62

- 2-denier microfiber: 0.89

That is a 43% improvement. Zero extra material cost. Just different fiber.

The trade-off? Microfiber felts are harder to needle-punch. The fine fibers break more easily. Our needle breakage rate went up 18% when we switched. We had to slow the line from 8 meters/minute to 6.2. Labor cost increased. But the acoustic performance justified it.

We now offer "Acoustic Micro" grade. 100% microfiber PET, 320 gsm, NRC 0.85 on 25mm panel. It's our bestseller for recording studios and home theaters. The acoustic performance of microfiber nonwovens matches what we see in production.

Can recycled polyester achieve the same acoustic performance as virgin?

Yes. But you must control the melt flow.

Recycled PET flakes come from bottles. Different bottles have different intrinsic viscosities. Some are from soda bottles (higher IV). Some are from water bottles (lower IV). When you melt and respin them, the fiber diameter consistency suffers.

In 2021, we ran a trial: 100% rPET microfiber felt. The acoustic test results were all over the place. One sample: NRC 0.82. Next sample from same roll: NRC 0.67. Inconsistent fiber diameter caused inconsistent airflow resistivity.

We fixed it by blending.

Now our "Green Acoustic" grade is 70% rPET / 30% virgin PET. The virgin fiber stabilizes the melt spinning. Fiber diameter variation drops from ±2.1 microns to ±0.8 microns. Acoustic consistency? ±0.03 NRC across the roll.

Is it 100% recycled? No. But it's 70%. And it performs identically to 100% virgin. LEED points still count it. The GRS certification requirements for recycled acoustic materials accept blends. We just disclose the percentage.

We have shipped 1.1 million meters of Green Acoustic since 2022. Mostly to European corporate offices with net-zero commitments. They pay a 15% premium. They don't compromise on sound.

How Does Fabric Construction Impact Sound Absorption?

I had a client in 2020 who insisted on woven acoustic fabrics.

He said: "Nonwovens look cheap. I want woven texture. Herringbone. Basket weave."

We made him a woven jacquard acoustic fabric. 380 gsm. Beautiful. Installed in a Miami law firm lobby. Looked like expensive upholstery.

Sounded like a cafeteria.

We tested it. NRC: 0.31. The weaving process compresses yarns tightly. Air can't move through. Sound reflects.

Here is the hierarchy of acoustic construction:

- Nonwoven needle-punch — Best. Random fiber orientation, high porosity, excellent friction.

- Nonwoven thermal-bond — Good. Slightly less airflow than needle-punch, but smoother surface.

- Knitted spacer — Good for thin applications. Air gap inside traps sound.

- Woven open mesh — Fair. Only works if >40% open area.

- Woven tight construction — Poor. Decorative only.

Why do needle-punched nonwovens outperform woven fabrics for sound absorption?

Fiber orientation.

In a woven fabric, 90% of fibers lie parallel to the surface. Sound hits them, and most energy reflects. The fibers are like a wall of parallel logs.

In a needle-punched nonwoven, fibers are oriented randomly. Many fibers are perpendicular to the surface. Sound waves hit those vertical fibers tip-first. The wave penetrates. Friction happens along the entire fiber length.

We visualized this in 2021.

We took cross-sections of both constructions under microscope. Woven: clean layers, like plywood. Nonwoven: tangled forest, fibers pointing in every direction. The tangled forest absorbs. The plywood reflects.

We also tested needle density. Standard: 150 punches/cm². We tried 200 punches/cm². NRC dropped 7%. Too many needles over-compressed the web. Reduced porosity. We now run acoustic grades at 130–160 punches/cm² depending on weight.

The effect of needle-punch density on acoustic nonwovens is well studied. We keep our parameters within the optimal zone. Clients don't care about punch density. They care that the echo disappears.

When should we specify thermally bonded nonwoven instead of needle-punch?

Needle-punch has texture. Some architects hate it.

Thermal bonding uses heat to melt the outer layer of bicomponent fibers. The surface becomes smoother. You can print on it. You can laminate it. You can make it look like solid-colored felt, not "industrial batting."

Trade-off: Acoustic performance drops 8–12%.

In 2023, we supplied 22,000 meters of thermally bonded acoustic fabric to a Korean automotive interior supplier. Headliners for electric sedans. Needle-punch would have left fiber marks on the foam backing. Thermal bonding gave a clean surface for adhesive.

NRC dropped from 0.78 to 0.69. Still passed their spec (0.65 minimum). The smoother surface was worth the loss.

So my rule: If the fabric is visible and will be touched by humans daily, specify thermal bond. If it's hidden behind grille cloth or in plenum spaces, needle-punch is better and cheaper.

The comparison between needle-punch and thermal bond acoustic performance shows the trade-off clearly. We offer both. We let the client choose based on aesthetics vs performance.

What Certifications and Compliance Issues Affect Acoustic Fabric Sourcing?

Acoustic fabric lives on walls.

Walls have fire codes. Ceilings have fire codes. And increasingly, floors have fire codes.

Fabric that isn't flame-retardant certified cannot be installed in commercial buildings.

Full stop.

In 2018, we shipped 15,000 meters of beautiful wool-blend acoustic felt to a hotel in Singapore. No FR treatment—wool is naturally smolder-resistant, we thought. Singapore Civil Defence Force inspected. Failed the vertical burn test. The hotel had to rip out every panel and replace them. The supplier (us) paid for the replacement fabric. $128,000.

Never assume. Always test.

Here is the compliance matrix we use today:

| Market | Standard | What It Tests | Our Solution |

|---|---|---|---|

| USA | NFPA 701 | Vertical flame spread | Inherent FR polyester or topical treatment |

| USA | Cal TB 117 | Smolder resistance (upholstery) | FR backcoating |

| EU | EN 13501-1 | B-s1,d0 (non-combustible) | Modacrylic blends or FR additives |

| UK | BS 5867 | Flame retardancy for curtains | Wash-durable FR finish |

| Marine | IMO FTPC Part 8 | Smoke and toxicity | Low-smoke FR polyester |

| Aviation | FAR 25.853 | 12-second vertical burn | Aramid blends |

Can we achieve EN 13501-1 B-s1,d0 with 100% recycled polyester?

No. Not yet.

We tried in 2022. German architectural spec. Required B-s1,d0 for a museum acoustic installation. We formulated 100% rPET with 14% liquid FR additive. Passed the single-flame source test (EN 11925). Failed the main SBI test (EN 13823). FIGRA (Fire Growth Rate) was 185 W/s. Spec required <120 W/s.

The recycled feedstock had trace contaminants. Different melt points. The FR additive didn't distribute evenly.

We switched to 50% rPET / 50% virgin PET with modified FR chemistry. FIGRA dropped to 98 W/s. Passed. Client accepted the blend.

So the honest answer: If you need the highest fire classification, virgin polyester or modacrylic blends are still more reliable. Recycled content may require derating.

We maintain current EN 13501-1 certification records for all acoustic grades. If a specifier asks, we send the third-party test report within 2 hours. Not a self-declaration. Actual Notified Body documentation.

How do we comply with California Proposition 65 for acoustic wall panels?

Prop 65 is a trap for unwary importers.

It doesn't ban chemicals. It requires warning labels if certain chemicals are present above "safe harbor" levels. Many acoustic fabrics use antimony trioxide as a synergist in FR systems. Antimony is on the Prop 65 list. Reproductive toxin.

In 2020, a client shipped our acoustic panels to a school in Los Angeles. The receiving inspector saw "antimony" on the MSDS. Rejected the shipment. Client had to apply Prop 65 warning stickers to 2,800 panels. Delayed installation by 3 weeks.

Now we offer antimony-free FR for all acoustic fabrics shipped to California.

We use a phosphorus-based system. More expensive (+$0.22/m). Zero antimony. Zero lead. Zero phthalates. Same NFPA 701 pass rate. The Prop 65 compliance guidance for textile imports changes frequently. We subscribe to updates. We don't guess.

At Shanghai Fumao, we pre-label any order destined for California. We don't wait for the client to ask. We assume they need it. Saves everyone headaches.

How Do Factory Seasons and Lead Times Impact Acoustic Panel Production?

Acoustic fabric is not a commodity.

You cannot call us on Monday and ask for 20,000 meters of FR-certified, NRC-tested, color-matched felt by Friday. Even if you offer double freight.

Why? Because acoustic fabric requires specialized production lines.

Our needle-punch lines run 24/7 during peak seasons. March–May: office fit-outs in Europe. August–October: hotel renovations in the Middle East. Both want delivery "before the season." Both wait their turn.

Here is the reality of acoustic fabric lead times:

| Fabric Type | Sample Development | Bulk Production (10k m) | With FR Certification | With GRS Certification |

|---|---|---|---|---|

| Standard PET felt | 5–7 days | 18–22 days | +5 days | +10 days |

| Microfiber acoustic | 7–10 days | 22–28 days | +5 days | +10 days |

| Wool blend | 10–14 days | 25–32 days | +7 days | N/A |

| Custom color match | 10–15 days | +7 days to bulk | +5 days | +10 days |

Add 14–21 days if you order during peak season. We don't hide this. We publish it.

How do we secure acoustic felt inventory before Chinese New Year?

CNY is brutal for nonwovens.

Why? Because staple fiber production stops. Recycled PET flake collection stops. Even trucking stops.

Our strategy: Pre-produce the felt, store it greige.

We run our needle-punch lines at 95% capacity in November–December. We produce standard weights: 300 gsm, 400 gsm, 500 gsm. White only. We stockpile 500,000+ meters in our climate-controlled warehouse.

Then in January–February, when the client finally approves the color, we piece dye it. Dyehouses run limited schedules during CNY, but they run. We have contracts with three dyehouses that keep one line open specifically for our acoustic felts. We pay 25% premium. Worth it.

In 2023, this saved a Swedish client.

They ordered 18,000 meters of navy acoustic felt on January 15. CNY started January 22. We pulled greige felt from stock. Shipped to dyehouse January 17. Dyeing finished January 20. Heat-set and finished January 21. Loaded container January 22—the last truck out of Keqiao before the holiday.

They got fabric. Their competitors didn't.

The inventory hedging strategies for acoustic nonwovens are not complicated. Just expensive. We carry the cost. Clients benefit.

What is the realistic timeline for custom acoustic color development?

Color matching acoustic felt is harder than color matching woven fabric.

Why? Because needle-punch felt has depth.

Light hits the surface fibers, penetrates between fibers, reflects off fibers at different depths. The perceived color is a blend of surface and subsurface reflections. A spectrophotometer reads it differently than the human eye.

We learned this in 2021.

A Japanese architect specified "warm gray." We delivered a lab dip. Delta E 0.4. Perfect. They installed 8,000 panels. Then the architect visited the site. "This is too blue," he said.

We measured again: Delta E 0.6. Still within tolerance. But against the concrete floor and the oak ceiling, the gray looked cold. The spectrophotometer didn't see what the eye saw.

Now our acoustic color development protocol includes:

- Standard lab dip (Delta E < 1.0)

- Large mock-up (1m x 1m) viewed in client's actual lighting environment

- If possible, installation of 5 panels on-site before bulk production

- Approval sign-off that includes "visual acceptance" clause, not just numbers

This adds 10–14 days. It eliminates 90% of post-installation color complaints.

We also maintain a digital color library of 1,200+ acoustic felt shades. Clients can browse, select, and we ship greige-stock-dyed colors in 12 days. Custom colors take longer. But the library keeps growing.

Conclusion

The best fabric for sound absorption is not one fabric.

It is the fabric that balances NRC target, fire safety, budget, aesthetics, and delivery timeline. Sometimes that means microfiber polyester at 320 gsm with EN 13501-1 certification. Sometimes that means recycled PET felt at 400 gsm with antimony-free FR for a California school. Sometimes that means wool blend for a luxury hotel lobby that will never host a fire inspection anyway.

I have made every mistake in this article.

I shipped acoustic fabric that didn't absorb because I confused weight with performance. I trusted a supplier's NRC claim without verifying the test frequency. I assumed wool was safe from fire codes. I matched a color to Delta E 0.4 and still got rejected because the lighting made it look cold.

Those mistakes cost us. Hundreds of thousands of dollars. But they also taught us how to do it right.

Today, at Shanghai Fumao, we do it right.

We test every acoustic production lot in our own impedance tube. We maintain third-party certifications for FR, GRS, and OEKO-TEX. We stockpile greige felt before Chinese New Year so our clients don't miss their installation windows. We offer antimony-free FR for California without being asked.

We are not a trading company that happens to sell acoustic fabric. We are a manufacturer that engineered our entire nonwovens line around acoustic performance.

So if you are specifying fabric for a recording studio, a corporate headquarters, a hotel, or a home theater—talk to us.

Email Elaine, our Business Director, directly: elaine@fumaoclothing.com.

Tell her what you are building. Tell her your NRC target. Tell her your fire code jurisdiction. Tell her your deadline.

She will connect you with our acoustic textiles team. We will pull the fiber samples. We will run the impedance tube test. We will develop the color mock-up. We will build the production schedule that accounts for the peak season backlog and the dyehouse lead times.

We won't promise you the cheapest felt. We will promise you sound absorption that performs, fire safety that complies, and delivery that meets your installation date.