As a fabric supplier with over two decades in the textile hub of Keqiao, I’ve seen the demand for medical and hygiene textiles skyrocket. Customers often come to me confused, asking, "What fabric is truly best for my disposable gowns or reusable wipes?" They worry about protection, comfort, cost, and complex certifications. It’s not just about picking a material; it’s about balancing performance with real-world production timelines and supply chain realities.

The best fabrics for medical and hygiene products are non-wovens (like SMS and spunbond-meltblown-spunbond composites) for single-use protective gear, and high-performance wovens or knits (like tightly woven polyester-cotton blends and antimicrobial jersey) for reusable applications. The ultimate choice depends on the specific product’s barrier requirements, breathability needs, durability, and whether it’s designed for single-use or multiple uses. For instance, a surgical gown fabric must pass completely different tests than fabric for hygienic bed linens.

Let’s cut through the noise. I’ll break down the fabric options not just by type, but by the actual end-use. We'll look at the pros, cons, and the behind-the-scenes production knowledge that can make or break your project, especially when planning around China’s manufacturing cycles.

What Non-Woven Fabrics Dominate Single-Use Medical Products?

When we talk about disposable medical products—isolation gowns, drapes, masks, caps—non-wovens are the undisputed king. They are engineered for a specific, short life cycle, prioritizing barrier protection, fluid resistance, and cost-effectiveness. The magic isn't in the fiber alone, but in how the fibers are bonded together to create a fabric without weaving or knitting.

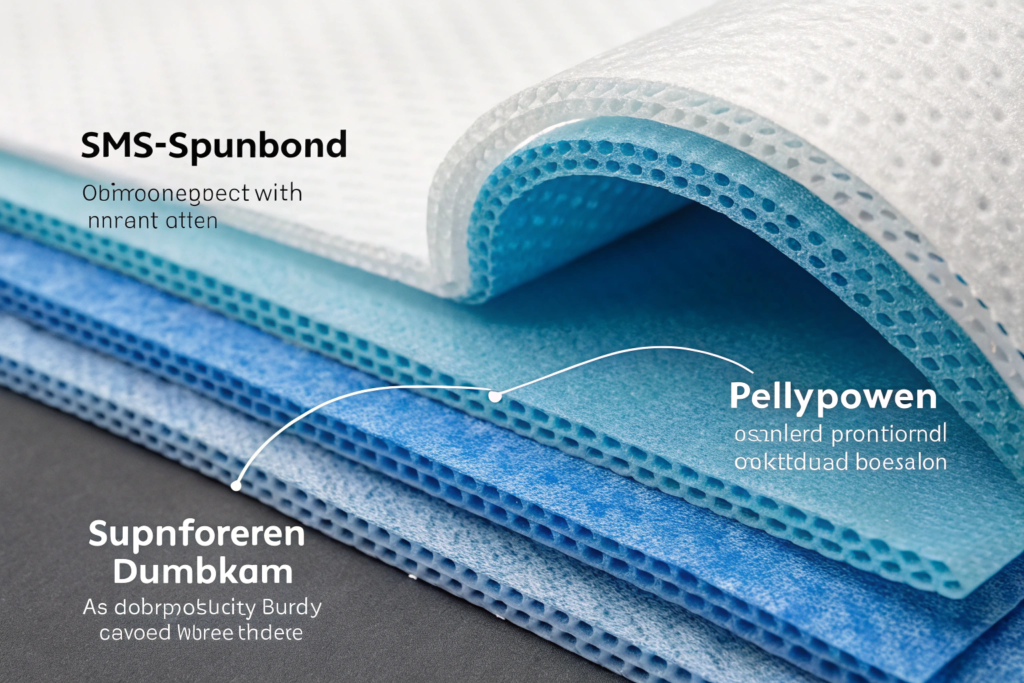

The key advantage is the ability to design the fabric's properties layer by layer. Think of it like a sandwich. A common and superior structure is SMS (Spunbond-Meltblown-Spunbond). The outer Spunbond layers provide strength and durability, the middle Meltblown layer is the workhorse for barrier and filtration, and the bottom Spunbond layer adds more strength and determines the feel against the skin. This combo creates an optimal balance that a single material can't achieve. For sourcing these critical materials, understanding how to evaluate spunbond polypropylene suppliers for medical grades is a fundamental step for any serious procurement professional.

How Does Fabric Structure Determine Protection Level?

Protection level isn't just about thickness; it's about pore size, hydrostatic pressure resistance, and breathability. Here’s a simple breakdown:

| Fabric Type (Non-Woven) | Typical Construction | Key Properties | Best For |

|---|---|---|---|

| Spunbond Polypropylene | Single layer, thermally bonded fibers. | Good strength, moderate breathability, basic barrier. | Medical caps, shoe covers, low-fluid exposure applications. |

| SMS Composite | 3-layer (Spunbond-Meltblown-Spunbond). | Excellent strength, high fluid barrier (≥ 50 cmH2O), good breathability. | The industry standard for Level 3-4 surgical/isolation gowns, drapes. |

| Flashspun Polyethylene (e.g., Tyvek®) | Very fine, continuous filaments bonded. | Exceptional dry particle and chemical barrier, low lint. | High-protection environments like cleanrooms, hazardous material handling. |

The choice here is critical. For example, in early 2023, a European distributor urgently needed Level 3 isolation gowns. They initially sourced a cheaper, dense spunbond fabric that failed the breathability test, causing clinician discomfort. We quickly pivoted to producing an SMS fabric with a precise meltblown weight, which passed both the barrier (ASTM F1670) and breathability (ASTM F1868) tests. The order was shipped within 25 days by leveraging a pre-scheduled production slot at our cooperative factory.

Why Are Material Certifications Like ISO 13485 Non-Negotiable?

You can have the best fabric, but without the right paperwork, it’s useless for the medical field. Certifications are your quality passport. ISO 13485 is the international standard for a Quality Management System (QMS) specific to medical devices. If a fabric mill has this, it means their entire process—from raw material inspection to storage and shipping—is documented and controlled for traceability.

Beyond the factory certification, the fabric itself needs validation. This is where test reports from accredited labs like SGS or Intertek come in. Key tests include:

- Resistance to Synthetic Blood Penetration (ASTM F1670): Simulates exposure to blood-borne pathogens.

- Resistance to Viral Penetration (ASTM F1671): A more stringent barrier test.

- Breathability (MVTR - ASTM E96): Measures moisture vapor transmission rate.

I recall a client from the US in late 2022 who learned this the hard way. They imported a container of surgical gowns, only to have them rejected at customs because the supplier could only provide a generic "quality report," not a lab-accredited test against the specific ASTM standards. The entire shipment was held up for weeks. At Shanghai Fumao, our in-house CNAS-accredited lab runs these tests as a standard part of our development process, and we provide the full, verifiable reports. It’s not an extra cost; it’s a necessity. For a deeper dive into compliance, the FDA's guidance on medical gowns is an essential resource for any importer.

Which Woven and Knitted Fabrics Are Ideal for Reusable Hygiene Textiles?

For products that are laundered and reused—surgical scrubs, patient gowns, barrier bedsheets, high-quality healthcare uniforms—woven and knitted fabrics take center stage. Here, the game changes from disposability to durability. The fabric must withstand industrial laundering (high temperatures, harsh detergents, abrasion) dozens, even hundreds of times, while maintaining its color, integrity, and protective properties.

The focus shifts to fiber blends and fabric construction. A classic and proven champion is a 65% Polyester / 35% Cotton tightly woven poplin or twill. The polyester provides strength, wrinkle resistance, and dimensional stability through washes. The cotton adds comfort, absorbency, and a natural feel against the skin. For superior performance, this blend is often treated with a Durable Water Repellent (DWR) finish or a permanent antimicrobial treatment.

What Makes a Fabric "Healthcare-Laundry Proven"?

It’s all about the technical specs that go beyond feel. When we develop reusable hygiene fabrics at Shanghai Fumao, we target these benchmarks:

- Tensile & Tear Strength (ASTM D5034/D5587): Must be high to resist ripping during use and laundering.

- Dimensional Stability (AATCC 135): Shrinkage must be controlled, typically under 3%, after multiple washes.

- Colorfastness to Washing & Chlorine Bleach (AATCC 61/AATCC 172): Colors cannot fade or bleed, which is crucial for professional appearance and infection control protocols.

- Antimicrobial Efficacy (AATCC 100 or JIS L 1902): For treated fabrics, they must demonstrate a high reduction rate (>99.9%) of bacteria like S. aureus and E. coli even after 50+ washes.

We worked with a large nursing home chain in Australia in Q3 2023. They needed barrier bedsheets that could handle 150+ industrial washes without pilling, fading, or losing their fluid-resistant finish. We engineered a 60/40 Poly-Cotton twill with a proprietary fluorocarbon-free DWR finish and embedded silver-ion antimicrobial agent. After providing them with pre-production samples for their own wash-testing, they confirmed the fabric met their 150-wash cycle standard, leading to a steady quarterly order. The key was our integrated control from weaving to finishing.

How Do Functional Finishes Enhance Reusable Textiles?

The base fabric is just the canvas. The functional finishes are the masterpiece. Here are the critical ones:

- Antimicrobial Finish: This is not just for odor control; it's a critical infection prevention feature. Technologies like silver ions, zinc pyrithione, or quaternary ammonium compounds are bonded to the fiber. They disrupt the cell membranes of bacteria, preventing their growth on the fabric surface.

- Fluid-Repellent Finish (DWR): Creates a surface tension that causes fluids to bead up and roll off rather than soak in. The industry is rapidly moving away from traditional PFAS-based (C8) chemistry to safer, eco-friendly water repellent technologies for medical textiles that are fluorine-free but still effective.

- Anti-Static Finish: Crucial in environments with sensitive electronic equipment or where comfort is paramount.

Applying these finishes consistently at an industrial scale is where many factories struggle. The recipe, temperature, drying speed, and curing time must be exact. (Here’s a pro tip: always ask for a wash durability report for the finish, not just the virgin fabric). An inconsistent finish will wash out quickly, leaving you with a standard fabric. Our partnership with a dedicated coating and finishing factory allows us to monitor these parameters in real-time, ensuring every meter meets the spec.

How to Balance Performance with Cost and Sourcing Timelines?

This is the million-dollar question I get from buyers like Ron every day. You want Level 4 protection, EU-certified eco-material, a 4-week lead time, and a rock-bottom price. In the real world of manufacturing, you can pick three. Understanding the trade-offs and planning strategically is what separates successful projects from logistical nightmares.

Cost is not just the price per meter. It’s the Total Landed Cost: fabric cost + manufacturing + testing/certification + shipping + tariffs + inventory holding costs. A cheaper fabric that fails QC and causes a production delay can cost you ten times more in the long run. For example, opting for a slightly heavier GSM (grams per square meter) in an SMS fabric might increase the fabric cost by 5%, but it could boost your yield (number of gowns per roll) by reducing cutting waste and increase your pass rate on barrier tests, saving you money overall.

Why Should You Align Production with China's Manufacturing Calendar?

This is where most first-time importers stumble. Our industry has predictable rhythms:

- Peak Seasons (Mar-May, Aug-Oct): Factories are at 100-120% capacity. Lead times stretch by 1-2 weeks. This is the time to place orders for your core, forecasted inventory.

- Major Holidays (Chinese New Year, National Day): Chinese New Year is a 3-4 week full stop. The rule is: all pre-production (fabrics, trims, tech packs) must be confirmed and in the factory at least 6 weeks before the holiday. A smart European fashion brand we work with now completes their fabric order with us by early December for CNY production, so the garment factory can start sewing the day after reopening.

- Slower Periods (Jun-Jul, Nov-Dec): This is your window for rapid prototyping, small-batch testing, and negotiating better prices. Factories have more bandwidth. We pushed a development project for a US startup for compostable non-woven fabrics from PLA in July 2023, and from sample to first bulk delivery took just 5 weeks.

How Can a Local Partner Mitigate Supply Chain Risks?

Partnering with a supplier who acts as your eyes and ears on the ground is invaluable. Your partner should:

- Manage Multi-Factory Production: For a complex order like isolation gowns, the non-woven fabric, the lamination for reinforcement, the sewing, and the packaging might happen in four different specialized factories. A partner like Shanghai Fumao coordinates this entire chain.

- Conduct In-Process Quality Checks (IPQC): Our QC team doesn’t just inspect the final product. They check the fabric roll at the weaving mill, the color consistency after dyeing, the finish application, and the cut pieces before sewing. This prevents a single point of failure from ruining an entire batch.

- Navigate Logistics and Tariffs: Since 2018, US tariffs have been a major pain point. Our solution has been diversification: for US-bound medical textiles, we often recommend producing in our partner facilities in Southeast Asia or using tariff-engineered fabric constructions. We handle the export documentation, consolidated shipping strategies for textile importers, and customs clearance instructions, turning a headache into a checkbox.

What Are the Sustainable Trends Shaping the Future?

The trend is irreversible: the future of medical and hygiene textiles is green. It’s driven by hospital sustainability mandates, consumer awareness, and brand responsibility. The challenge is achieving eco-credentials without compromising performance. This is where advanced material science comes in.

We are moving beyond "recycled polyester" into next-gen biopolymers. Materials like Polylactic Acid (PLA), derived from corn starch or sugarcane, can be engineered into non-wovens that are compostable under industrial conditions. Similarly, cellulose-based fibers from sustainably managed forests are being used to create flushable and biodegradable wipes substrates. The key for buyers is to look for credible, third-party certifications like OK Compost Industrial (TÜV AUSTRIA) or the Forest Stewardship Council (FSC) label.

Are Biodegradable Non-Wovens Truly Practical Today?

Yes, but with clear boundaries. Current-generation PLA non-wovens are excellent for lower-acuity products like exam gowns, patient drapes for non-sterile procedures, and certain wipes. Their strength and barrier properties are constantly improving. However, for the highest-level surgical barriers where absolute reliability is non-negotiable, traditional PP-based SMS is still the benchmark. The industry is in a transition phase. A practical strategy is to start integrating biodegradable options into lower-risk product lines to build experience and meet sustainability KPIs, while relying on proven materials for critical applications. Research institutions like The Nonwovens Institute are excellent sources for staying updated on these material advancements.

How Does a "Circular Economy" Model Work for Medical Textiles?

For reusable textiles, the circular model is about extending life and responsible end-of-life. This involves:

- Design for Longevity: Using the high-durability fabric blends we discussed.

- Design for Recyclability: Using mono-material constructions (e.g., 100% polyester knit) that are easier to recycle than complex blends.

- Take-Back Programs: Some pioneering European healthcare groups are working with suppliers to collect end-of-life textiles (like worn-out scrubs and linens) to be mechanically recycled into industrial wiping cloths or insulation material.

Implementing this requires close collaboration from the fiber producer, the fabric mill, the garment maker, and the end-user. It's complex, but it's the definitive endgame. As a supplier deeply invested in this future, Shanghai Fumao has allocated significant R&D resources, including a ¥550M green investment fund, to partner with clients who want to pioneer these solutions. Our development team can guide you through the available options, performance trade-offs, and credible certification pathways for sustainable medical textiles.

Conclusion

Choosing the best fabric for medical and hygiene products is a strategic decision that hinges on the product's intended use, performance requirements, and total lifecycle cost. There is no universal "best" fabric, but there is an optimal fabric for your specific application. For single-use, high-barrier protection, look to multi-layer non-wovens like SMS with full ASTM test reports. For durable, reusable items, focus on robust woven or knitted blends enhanced with durable functional finishes. Remember to factor in the real-world rhythms of manufacturing and align your planning with industry cycles to secure capacity and timely delivery.

Ultimately, success in this field depends on a partnership built on technical expertise, transparent communication, and verified quality. It's about finding a supplier who doesn't just sell you fabric, but who provides a solution grounded in real-world production knowledge and a commitment to your product's success from the first lab dip to the final shipment.

Ready to translate this knowledge into a successful product line? Partner with a supplier who understands both the science of fabric and the realities of global supply chains. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how Shanghai Fumao can co-create the precise, reliable, and cost-effective textile solutions your medical or hygiene brand needs. Let's build something better, together.