You're developing a pair of high-performance leggings that must hold their shape through a marathon, or a medical compression sleeve that requires precise, consistent pressure. You know you need stretch, but you get samples that sag after a few wears or lose their grip. The problem isn't just about "having spandex"—it's about engineering and specifying the exact elasticity (stretch) and recovery (return) properties your product demands. How do you translate a functional need into a technical fabric specification that any mill can understand and execute?

Sourcing for elasticity is a precision science. It's not enough to ask for "stretchy fabric." You must define the direction of stretch, the percentage of elongation under a specific force, and the critical metric of how completely it snaps back—its recovery percentage. A 30% stretch with 70% recovery is a saggy disaster; 30% stretch with 95% recovery is performance-grade. The gap between them is in the fiber quality, knit construction, and finishing chemistry.

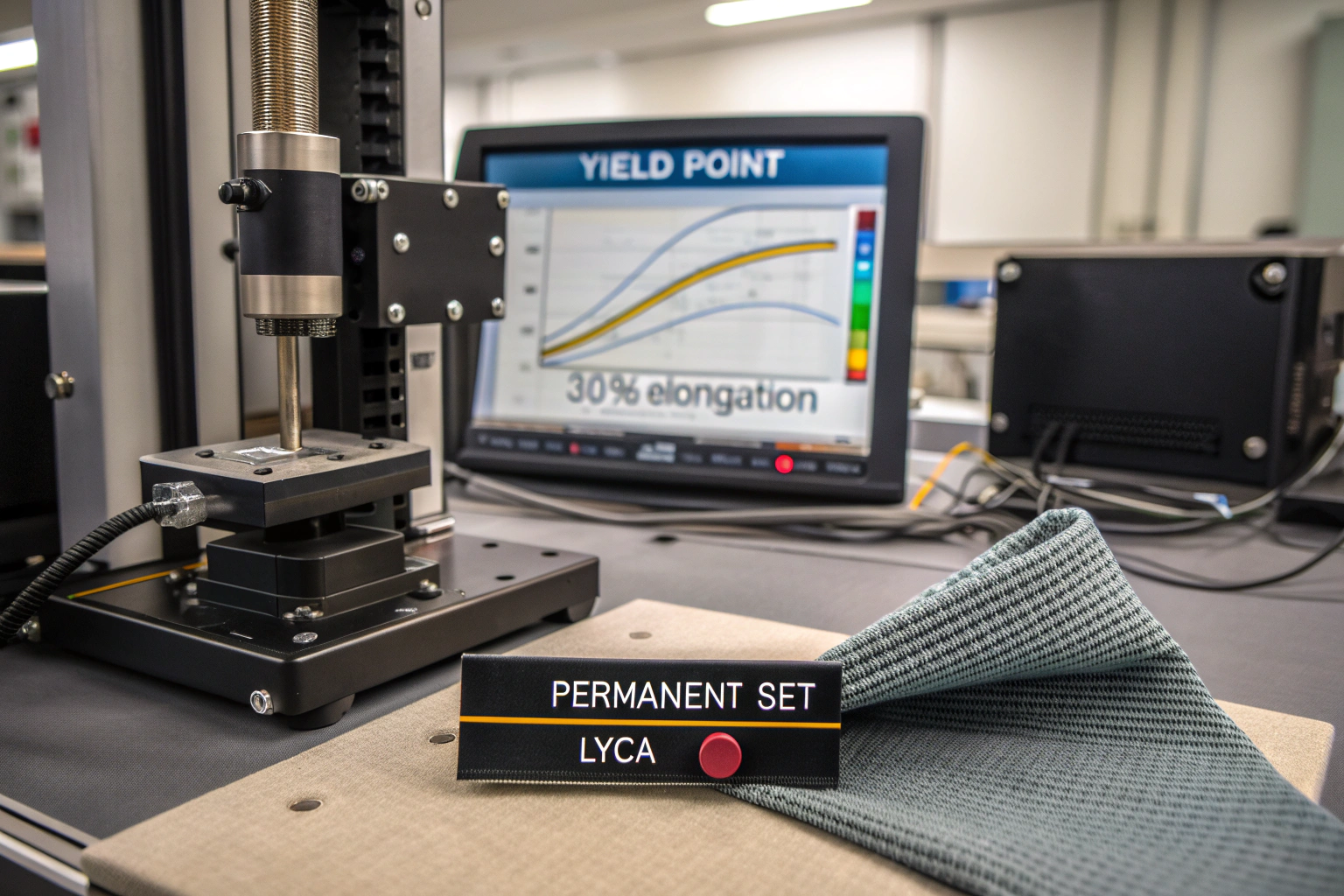

In our Keqiao lab at Shanghai Fumao, we run cyclic recovery tests daily for activewear, swimwear, and intimate apparel brands. The difference between a bestseller and a product return is often a 5% variance in recovery after 20 wash cycles. Let's build a technical framework to specify, source, and validate stretch fabrics with scientific accuracy.

What are the key technical terms and metrics for stretch?

Before you can specify, you must speak the language. The textile industry uses standardized terms and test methods to quantify stretch behavior. Confusing these terms leads to miscommunication and failed prototypes. Think of this as learning the vocabulary of fabric mechanics.

Elasticity is not a single property; it's a system of interdependent behaviors under tension and release.

What do elongation, modulus, and recovery actually mean?

- Elongation (Stretch %): The maximum percentage a fabric can be stretched before it yields or breaks. It's measured in specific directions:

- Coursewise (Widthwise) Stretch: Most common in weft knits (like jersey).

- Walewise (Lengthwise) Stretch: Less common, but critical for certain applications like compression sleeves.

- Bias Stretch (45° angle): Often the greatest stretch direction.

- How it's Measured: A strip of fabric is clamped and extended at a constant speed until a specified force is reached (e.g., 15 Newtons). The increase in length is reported as a percentage. "30% stretch" is meaningless without the force parameter.

- Modulus: This describes the "feel" of the stretch—how much force is required to stretch it. It's the slope of the stress-strain curve.

- Low Modulus: Stretches easily with little force (e.g., a loose, comfortable t-shirt).

- High Modulus: Requires significant force to stretch (e.g., a strong powernet for shapewear).

- Recovery (or Growth): The most critical metric. This measures how much the fabric permanently deforms after being stretched and released.

- Measured as "Permanent Set %": After cyclic stretching (e.g., 500 cycles at 30% elongation), the fabric is relaxed. If it grows from 10cm to 10.3cm, it has a 3% permanent set, meaning 97% recovery.

- Poor Recovery (<90%): Fabric bags out, loses shape.

- Good Recovery (95%+): Essential for athletic wear, swimwear, and any product requiring shape retention.

For a yoga legging, you might specify: "Fabric must achieve 40% coursewise elongation under 10N force with ≤5% permanent set after 500 stretch cycles (ASTM D2594)." This is an unambiguous, testable spec.

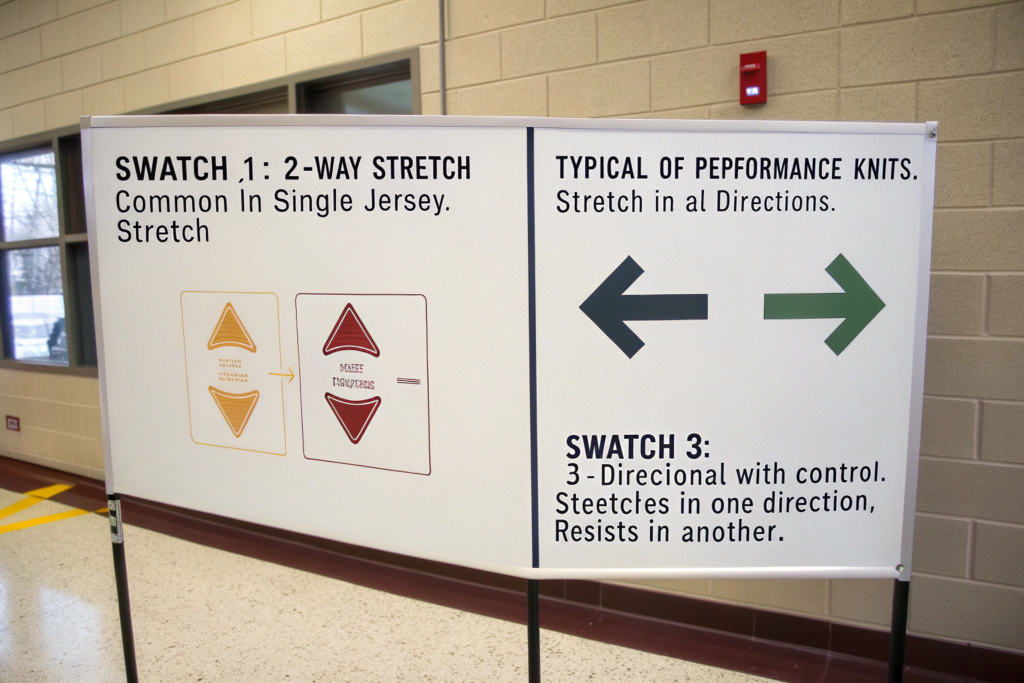

How are 2-way vs. 4-way stretch different in construction?

This refers to the directions in which the fabric stretches significantly.

- 2-Way Stretch: Fabric stretches significantly in one direction only (usually widthwise). Common in many basic knit jerseys. Achieved with weft knitting and spandex only in the coursewise direction.

- 4-Way Stretch (or Multi-Directional Stretch): Fabric stretches significantly in both length and width, and often on the bias. This is the hallmark of high-performance activewear, swimwear, and compression garments.

- How it's Made: Through specific warp knit constructions (like powernet, satinet) or circular knits using spandex in both the warp and weft directions. The knit structure itself is engineered for omnidirectional movement.

A sports bra requires true 4-way stretch to accommodate complex chest movement, while a t-shirt might only need 2-way stretch.

What fibers and constructions deliver specific stretch performance?

The stretch character is born from the marriage of fiber and structure. Spandex (Lycra®, elastane) is the engine, but the surrounding fibers and how they're knitted or woven determine the durability, handfeel, and ultimate recovery of the fabric.

You are building a composite system: the elastane provides the power, the companion fibers provide the strength and aesthetics, and the construction dictates the direction and feel.

What is the role of spandex (Lycra®) type and percentage?

Not all spandex is the same. Its denier (thickness) and inherent properties are chosen for the job.

- Spandex Denier: Finer denier (e.g., 20D, 40D) is used for lightweight, soft stretch in garments like t-shirts or lingerie. Heavier denier (e.g., 70D, 140D) is used for high-power applications like swimwear, athletic leggings, or compression wear, where strong, resilient stretch is needed.

- Spandex Percentage: This is a careful balance.

- 2-5%: Light, comfortable stretch for everyday knits.

- 10-20%: Moderate to strong stretch for activewear basics.

- 20-30%+: High-power stretch for performance sportswear, shapewear, and compression garments.

- The Trade-off: Higher spandex content improves recovery but increases cost, can affect moisture management, and may lead to a hotter, less breathable fabric if not constructed properly.

- Spandex Brand & Quality: Generic elastane can degrade faster with exposure to chlorine, sweat, or UV light. Branded fibers like Lycra® T862 (for chlorine resistance in swimwear) or Lycra® Sports Technology offer guaranteed performance benchmarks. Always specify the brand and type if you have critical needs.

We developed a running legging fabric using 88% Polyester, 12% Lycra® Xtra Life (a high-durability variant). The specific Lycra® type was chosen for its exceptional resistance to degradation from sweat and repeated washing, which was the key to maintaining recovery over the garment's lifespan.

How do knit structures (jersey, rib, powernet) affect elasticity?

The knit pattern is the chassis that holds the engine.

- Single Jersey: The basic knit. Offers good 2-way stretch. Recovery depends heavily on spandex quality and finishing.

- Rib Knit (1x1, 2x2): Has excellent crosswise stretch and recovery due to its alternating knit-and-purl structure. Used for cuffs, collars, and bodysuits where high recovery is needed to maintain tight fit.

- Interlock: A double-knit, more stable, with less stretch but better recovery than single jersey of the same composition. Used in polo shirts where a crisp look with some give is needed.

- Powernet: A warp knit structure. The gold standard for controlled, high-modulus stretch with exceptional recovery. The spandex is laid in under high tension during knitting, creating a powerful "spring-back." Used in shapewear, medical compression, and high-support activewear.

- Satinet/Microfiber Knits: Dense, fine-gauge warp knits that offer 4-way stretch with a smooth, sleek hand. Common in premium swimwear and athleisure.

Specifying the construction is as important as the fiber mix. For a compression sock, you would source a graduated compression powernet, not a jersey.

How to test and validate stretch specifications before bulk order?

Your approved handfeel sample might feel perfect, but will 10,000 meters of fabric perform the same? Without rigorous, standardized testing, you are gambling. The pre-production validation phase is where you convert subjective "feel" into objective, reproducible data that becomes your quality contract with the mill.

This process protects you from the most common and costly failure in stretch fabrics: inconsistent performance in bulk.

What are the essential physical and lab tests?

Never skip these. They should be performed on both your approved prototype fabric and the mandatory Pre-Production (PP) sample from the bulk dye lot.

- Stretch & Recovery Test (ASTM D2594 / ISO 20932-1): The benchmark. The fabric is cyclically stretched to a specified elongation (e.g., 30%) for a set number of cycles (e.g., 100). The permanent set is measured. This simulates garment wear.

- Tensile Strength & Elongation at Break (ASTM D5034): Measures the force needed to break the fabric and its maximum stretch. Ensures basic durability.

- Growth Test (for certain applications): The fabric is stretched to a specified extension, held for a set time (e.g., 30 minutes), released, and measured after recovery. This is key for items under constant tension, like socks or waistbands.

- Wash Testing (AATCC 135): Perform stretch and recovery tests after 5, 10, and 20 home launderings. This reveals if recovery degrades over time due to spandex fatigue or poor dyeing/finishing chemistry.

At our CNAS-accredited lab, we provide clients with a Stretch Performance Profile for their PP sample, showing graphs of load vs. elongation and a table of recovery percentages after multiple cycles and washes.

How to create a fail-proof tech pack for stretch fabrics?

Your tech pack is your legal and technical bible. For stretch fabrics, it must include a dedicated "Mechanical Properties" section.

- Specification Table Example:

| Property | Test Method | Your Requirement | Tolerance | Notes |

|---|---|---|---|---|

| Coursewise Elongation | ASTM D2594 @ 15N | 40% Minimum | ±5% | For comfort stretch |

| Permanent Set (after 100 cycles @ 30%) | ASTM D2594 | ≤ 4% | - | Critical for shape retention |

| Walewise Elongation | ASTM D2594 @ 15N | 20% Minimum | ±5% | For 4-way movement |

| Fabric Weight (GSM) | ISO 3801 | 210 g/m² | ±5% | |

| Spandex Content | AATCC 20A | 18% (±1%) | Specify brand (e.g., Lycra®) | |

| Recovery after 10 Washes | AATCC 135 + D2594 | ≥ 92% |

- Reference Sample: Physically attach a swatch of the approved fabric to the tech pack. This is the gold standard for handfeel and color.

- Finishing Instructions: Specify any heat-setting or relaxation processes required, as these can dramatically affect final dimensions and stretch.

This level of detail eliminates "he said, she said" and gives the mill a clear target to hit. It also gives your QC team a checklist for incoming inspection.

What are common sourcing pitfalls and how to avoid them?

Even with good specs, the path is mined with potential errors in communication, supplier capability, and cost engineering. The most common mistakes come from assumptions and a lack of supply chain transparency.

Forewarned is forearmed. Knowing these pitfalls allows you to navigate around them.

Why does "fabric relaxation" cause massive sizing issues?

This is the #1 surprise for brands new to stretch knits. Fabric fresh off the knitting machine is in a tense, unstable state. It must go through a controlled relaxation and heat-setting process to stabilize its dimensions and stretch properties. If you cut patterns based on un-relaxed fabric dimensions, your finished garments will shrink unpredictably after the first wash or steam.

- The Solution: Always demand the mill provide the finished, relaxed fabric width and shrinkage data (per AATCC 135). Your pattern maker must use these finished dimensions. Ask the mill: "What is the finished and stable width of this fabric after full relaxation?" The answer should be a single number (e.g., "150cm"), not a range.

How to avoid inconsistent quality across large rolls?

In a 10,000-meter order, the first and last 500 meters can behave differently if the production process drifts.

- Pitfall: Variations in spandex tension during knitting, dyeing temperature, or finishing can cause batch-to-batch differences in weight, stretch, and recovery.

- The Mitigation:

- In-line Monitoring: Partner with mills that have real-time monitoring of spandex feed tension and fabric weight.

- PP Sample from Bulk Dye Lot: As stated, this is non-negotiable. Test it rigorously.

- Roll-by-Roll Spot Checks: Agree that your QC or a third-party inspector can perform spot elongation tests on random rolls from the bulk shipment before it leaves the factory. Specify the AQL (Acceptable Quality Level).

A client once received a legging fabric where the recovery dropped from 96% to 88% mid-order. The cause was a faulty tensioner on one knitting machine that wasn't caught. Our solution was to implement a statistical process control (SPC) chart for spandex tension for all their future orders, preventing recurrence.

Conclusion

Sourcing fabric with specific elasticity and recovery is a disciplined exercise in applied textile engineering. It begins with mastering the precise language of elongation, modulus, and recovery, and translating functional needs into unambiguous technical specifications using standardized test methods. This knowledge then guides the selection of the right spandex type, percentage, and knit construction—whether it's a soft jersey or a high-power powernet—to deliver the desired mechanical performance. The entire process is safeguarded by rigorous pre-production validation through physical and lab testing, culminating in a detailed tech pack that serves as the quality contract. Finally, awareness of common pitfalls like fabric relaxation and production drift allows for proactive mitigation strategies, ensuring consistency from the first meter to the ten-thousandth.

This end-to-end, data-driven approach transforms stretch fabric sourcing from a risky gamble into a predictable, reliable component of product development. It ensures that the performance promised in the design phase is the performance delivered to the end customer, wear after wear.

If your product's success hinges on precise stretch and recovery—whether for athletic performance, medical efficacy, or lasting comfort—you need a partner who speaks this technical language fluently. At Shanghai Fumao, our technical textiles team specializes in developing, testing, and supplying engineered stretch fabrics with guaranteed performance data. From the first sample to bulk delivery, we ensure your specs are met with scientific precision. Contact our Business Director, Elaine, to specify your next project with confidence: elaine@fumaoclothing.com.