You've found a fabric supplier who delivers good quality on time. The transaction is smooth. But then a crisis hits: a dye lot is wrong, a port shuts down, or you need an impossible sample in a week. Your "good" supplier goes radio silent or sticks rigidly to the contract, leaving you stranded. You realize you don't have a partner; you have a vendor. So, how do you transform a simple buyer-seller dynamic into a resilient, strategic alliance that can weather storms and create mutual growth?

Building a long-term relationship isn't about friendship; it's about orchestrated mutual dependency and value creation. It's a deliberate business strategy that moves beyond price haggling to shared goals, transparent operations, and joint problem-solving. The supplier becomes an extension of your R&D, your risk mitigation team, and your innovation pipeline. This doesn't happen by accident—it's built through specific actions and a shift in mindset from both sides.

From our position at Shanghai Fumao, the most successful and profitable partnerships we have are with brands that treat us as a strategic mills department, not a catalog. These relationships survive market crashes, tariff wars, and pandemics because they are built on a foundation deeper than any single order. Let's blueprint how to construct this kind of partnership.

Why is a strategic partnership more valuable than multiple vendors?

The traditional sourcing playbook involves pitting suppliers against each other for the lowest price on every order. This is a short-term tactic that creates long-term fragility. A strategic partnership, in contrast, is an investment in supply chain resilience, innovation speed, and total cost of ownership. It's the difference between renting a tool and co-owning the workshop.

The value isn't measured in cents per meter saved today, but in millions of dollars of risk avoided and opportunities captured over five years.

How does partnership reduce risk and create stability?

When you're just another order number, you're the first to be deprioritized in a crisis. A partner has your name on a shortlist for protection.

- Capacity Guarantees: A partner will reserve production capacity for you during peak seasons (like pre-Chinese New Year rush) because they trust your forecast. You avoid the 8-week lead time becoming 12.

- Priority Problem-Solving: When a quality issue arises, a partner mobilizes their technical team immediately for root-cause analysis and replacement, often absorbing part of the cost. A transactional supplier sends an email blaming the yarn mill.

- Financial Buffer: In times of raw material price spikes (e.g., cotton crisis), a partner may honor quoted prices for a longer period or offer more flexible payment terms to help you manage cash flow. They see your long-term value.

- Geopolitical Agility: When tariffs hit or a regional lockdown occurs, a partner with multiple facilities (like our network in Keqiao and Southeast Asia) can transparently pivot production to the optimal location with you, managing the logistics.

For example, during the Suez Canal blockage, a long-term partner brand needed fabric urgently. Because we had visibility into their full production schedule, we could airfreight a partial shipment from our reserved stock to keep their lines running, while reorganizing ocean freight for the rest—a cost we shared. A new vendor would have said, "Not our problem."

What are the innovation and co-development advantages?

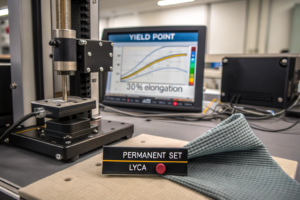

Your supplier's R&D lab is a resource you can't afford internally. A partnership unlocks it.

- Early Access: Partners get first look and exclusive periods on new sustainable fibers, performance finishes, and innovative weaves developed in the mill.

- Cost-Shared Development: Instead of you bearing the full $5,000 cost for a custom fabric development, a partner may co-invest, seeing it as a joint asset. The MOQ for that new fabric becomes lower because it's part of a shared roadmap.

- Shared Intellectual Property: You can develop truly unique fabrics with legal protection. We have partnerships where the brand owns the design, and we own the production process IP, creating a powerful, defensible moat for both.

A sportswear brand we've worked with for 8 years shares their 3-year trend and material roadmap with us. This allows our R&D team to proactively develop proof-of-concept samples around their themes, giving them a 6-month head start on competitors. That's partnership velocity.

What are the practical steps to initiate and deepen the relationship?

Turning a good supplier into a partner is a phased, intentional process. You can't walk in and ask for "partnership." You build it through demonstrated reliability, strategic communication, and shared investments. It's a courtship based on business integrity, not just volume.

Start by being the kind of client a supplier wants to invest in.

How to move from a first order to a strategic dialogue?

The foundation is laid in the first 6-12 months.

- Be a Model Client: Pay on time. Provide clear, complete tech packs. Give constructive feedback on samples. This seems basic, but 80% of buyers fail here, making you stand out.

- Share Your Business Story: In early conversations, go beyond the PO. Explain your brand's mission, your target customer, and your 2-year vision. This helps the supplier understand why you need certain qualities and where they can add value.

- Commit to Volume Predictability: Even if your volumes are small, offer a rolling forecast. "We plan to order this fabric every quarter in similar quantities." Predictability is more valuable than a single large, erratic order.

- Visit Them: If possible, go to their headquarters or factory. The cost of a trip to Keqiao is the best investment in trust you can make. You see their capability, meet the team, and shift from an email address to a person.

After a successful first year with a denim brand, we invited their head designer to our mill. Seeing our sustainable dyeing process and lab firsthand led to a co-development project for a new low-water wash technique—a conversation that never would have happened over email.

What should be in a partnership agreement beyond a contract?

A contract prevents problems; a partnership agreement enables growth. After establishing trust, formalize the framework.

- Joint Business Plan (JBP): An annual or bi-annual meeting to review: performance metrics (on-time delivery, quality pass rates), share sales forecasts, discuss innovation pipelines, and set mutual goals (e.g., "Reduce lead time by 10%," "Develop 2 new recycled fabrics").

- Key Account Management Structure: Designate single points of contact on both sides with decision-making power. At Fumao, our strategic partners have a dedicated Account Director and direct access to our technical and logistics managers.

- Transparent Costing Models: Move away from line-item haggling. Discuss an open-book costing model for key fabrics, where you understand the cost drivers (yarn, dye, labor) and share the goal of mutual margin improvement through efficiency, not squeezing.

- Exclusivity & Capacity Agreements: For truly proprietary developments, you might negotiate a period of exclusivity. In return, you guarantee a minimum volume, allowing them to confidently invest in specialized equipment.

This structured yet collaborative framework is what separates a partner from a preferred vendor.

How to maintain and grow the relationship over time?

A partnership is a living thing; it requires active nourishment. Complacency or taking the relationship for granted leads to erosion. The goal is to increase the "switching cost" not through contracts, but through embedded value that makes leaving inconceivably costly for both parties.

This is done through continuous improvement, shared learning, and expanding the scope of collaboration.

How to conduct effective joint business reviews?

The JBP meeting is the heartbeat of the partnership. It should be data-driven and forward-looking.

- Prepare a Scorecard: Review quantitative metrics: OTD%, Quality AQL results, Communication response time. Also review qualitative points: "How did we handle the crisis in Q3?" "What innovation project delivered the most value?"

- The "Win-Learn-Change" Framework:

- Win: What worked brilliantly? Celebrate it.

- Learn: What challenge did we face, and what did we learn from it?

- Change: Based on our wins and learns, what will we do differently next quarter?

- Set 3-5 Shared Objectives: Examples: "Achieve 98% OTD for SS25 season." "Qualify and source a new bio-based fiber together." "Reduce sampling lead time to 7 days."

These reviews transform the relationship from reactive to proactive and strategic.

How to expand collaboration into new areas?

Once the core fabric supply is solid, explore adjacent value.

- Supply Chain Financing: Partner with your supplier's bank or financial arm for inventory financing or factoring at better rates, improving your cash flow.

- Sustainability Audits & Reporting: Invite them to collaborate on your ESG reporting. They can provide verified data on water savings, carbon footprint, and recycled content for your products, adding credibility.

- Exclusive "Maker" Programs: Develop a sub-brand or capsule collection that is co-branded or exclusively manufactured with your partner, telling a powerful story of craftsmanship and partnership to your end-consumer.

- Problem-Solving Beyond Fabric: Use their local expertise. Need a new sewing factory in Vietnam? Logistics help in Shanghai? A true partner will make trusted introductions within their network.

We have a partner who was entering the European market and needed help with REACH compliance documentation. Our lab team worked directly with theirs to build the technical dossier, not just supply the compliant fabric. That's deep integration.

What are the warning signs of a deteriorating relationship?

Even the best partnerships need monitoring. Ignoring red flags can lead to a catastrophic, costly breakup. The signs are often subtle shifts in behavior and communication, not sudden failures.

Vigilance is part of stewardship. Catching issues early allows for course correction before the trust is broken.

How to spot communication breakdowns and eroding trust?

- Defensiveness & Blame-Shifting: When issues arise, the response is "your tech pack was unclear" or "the yarn mill is at fault," with no ownership or collaborative solution-finding.

- Declining Proactivity: They stop offering ideas, sharing market intelligence, or alerting you to potential problems ahead of time. Communication becomes purely transactional and reactive.

- Lack of Transparency: They become vague about costs, production status, or challenges. Requests for clarification are met with hesitation.

- Personnel Instability: Your main point of contact changes frequently, or you can never get through to decision-makers, getting stuck with junior staff.

When is it time to recalibrate or even exit?

Not all relationships are salvageable. Consider a formal recalibration or exit if:

- Repeated Core Failures: Consistent misses on quality, delivery, or documentation after clear agreements and attempts to correct.

- Strategic Misalignment: Their business direction shifts away from your needs (e.g., they stop investing in sustainable practices, which is core to your brand).

- Unethical Behavior: You discover falsified certifications, subcontracting without approval, or other integrity breaches.

- The "Partnership" is One-Sided: You are investing all the effort, transparency, and loyalty, but receiving only transactional service in return.

The end of a partnership should be handled with the same professionalism as its beginning. Conduct a formal off-boarding, fulfill contractual obligations, and provide clear, factual feedback. Burning bridges in a tight-knit industry like textiles is a poor long-term strategy.

Conclusion

Building a long-term relationship with your fabric supplier is a deliberate strategic investment that pays dividends in risk mitigation, innovation speed, and total cost efficiency. It begins by transitioning from a transactional, price-focused dynamic to one of demonstrated reliability and strategic dialogue, potentially formalized through joint business plans and transparent costing. This partnership is maintained through regular, data-driven reviews and expanded by collaborating on sustainability, financing, and exclusive development. However, it requires vigilant stewardship to spot and address early warning signs of erosion, ensuring the alliance remains mutually prosperous and resilient.

Ultimately, the strongest supply chain is not the one with the most suppliers, but the one with the fewest, deepest partnerships. In an unpredictable world, your fabric supplier should be a pillar of stability and a engine of growth, not a point of vulnerability.

If you are ready to move beyond transactional sourcing and build a fabric partnership that drives your brand forward, the conversation starts with a commitment to mutual value. At Shanghai Fumao, we are structured to be that partner, offering dedicated strategic account management, co-development initiatives, and complete supply chain integration. Let's discuss what a true partnership can look like. Contact our Business Director, Elaine: elaine@fumaoclothing.com.