You're designing a technical backpack for high-altitude treks or a waterproof jacket for Pacific Northwest trails. You need a fabric that can withstand abrasive granite, torrential rain, and UV degradation while weighing less than a water bottle. With hundreds of "high-performance" fabrics on the market, how do you decode the specs to find the material that won't fail when your customer is miles from the trailhead?

The best outdoor fabrics aren't chosen; they are engineered for a specific set of environmental and mechanical stresses. It's a triage of priorities: water protection vs. breathability, durability vs. weight, packability vs. insulation. The perfect fabric is the optimal compromise for a given activity, where a wrong choice means a soaked, frozen, or torn garment that can turn an adventure into an emergency.

At Shanghai Fumao, our technical textiles lab in Keqiao tests fabrics against simulated monsoons, abrasion from rock faces, and weeks of UV exposure. We've learned that the difference between a good and a great outdoor fabric lies in the microscopic details of its coating, the density of its weave, and the integrity of its lamination. Let's move beyond brand names and build a functional framework for selecting the right technical fabric for your gear.

What are the essential properties of outdoor fabrics?

Outdoor fabrics are defined by a core set of measurable performance attributes. Unlike fashion textiles, where aesthetics lead, here function dictates form. You must start by defining the non-negotiable performance thresholds for your product's intended use. These properties often exist in tension with one another; improving one can degrade another.

Understanding these trade-offs is the first step in speaking the language of technical textiles and specifying what you truly need.

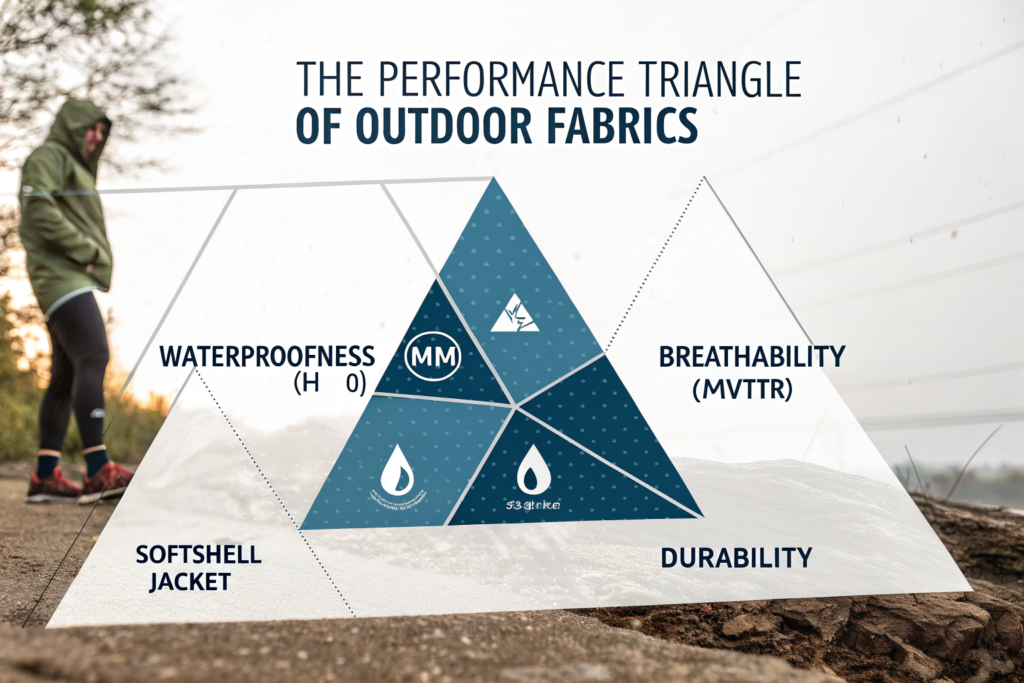

How do waterproofness, breathability, and durability interact?

This is the "Holy Trinity" of outdoor fabrics, especially for apparel.

- Waterproofness: Measured in millimeters of water column (mm H₂O). It indicates the pressure of water the fabric can withstand before leaking. A minimum of 10,000mm is considered waterproof for heavy rain. 20,000mm+ is expedition-grade.

- The Trade-off: Higher waterproofness often comes from thicker coatings or denser laminates, which can reduce breathability and increase weight.

- Breathability: Measured in grams per square meter per 24 hours (g/m²/24h), or more accurately, as Moisture Vapor Transmission Rate (MVTR). It quantifies how much sweat vapor can escape. A good benchmark is 15,000 g/m²/24h+.

- The Trade-off: Highly breathable membranes can be more delicate and expensive. Extreme breathability can sometimes come at a minor cost to ultimate waterproofness.

- Durability: Encompasses:

- Abrasion Resistance: Measured by Martindale or Taber tests. Critical for packs, knees, and shoulders.

- Tear Strength: Measured in Newtons (N). Prevents small punctures from becoming large rips.

- The Trade-off: Ultra-durable fabrics (e.g., high-denier Cordura®) are heavier and less packable.

For a 3-season hiking jacket, you might target 10,000mm waterproofness, 15,000g breathability, and a 4,000+ Martindale abrasion rating. A heavy-duty expedition backpack might prioritize 1,000D Nylon with a 100+ N tear strength and sacrifice packability.

Why is weight-to-strength ratio and packability critical?

Every gram counts when carried on your back for days.

- Weight-to-Strength: This is the engineering holy grail. Ripstop nylon is a classic example—a grid of thicker threads woven into a lighter fabric to stop tears with minimal weight penalty. High-tenacity yarns (like those used in Dyneema® or certain nylons) offer incredible strength at a very fine diameter.

- Packability: The ability of a fabric (and the garment made from it) to compress into a small space. This is influenced by fabric thickness, stiffness, and the memory of insulation (if any). Ultralight down-proof nylon shells (e.g., 7D-15D) excel here but sacrifice some durability.

- The Calculus: You must define the minimum acceptable durability for the use case, then find the lightest fabric that meets it. An ultralight tent inner wall might use 10D nylon, while the high-wear floor uses a 70D fabric with a silicone coating.

What are the key fabric technologies and constructions?

Outdoor fabrics are built in layers, each with a dedicated function. The magic is in how these layers are assembled. The two primary technological paths are Laminated Membranes and Densely Woven/Coated Fabrics. Choosing between them defines the character and capability of your final product.

This is where material science meets practical design. The construction determines not just performance, but also manufacturing complexity and cost.

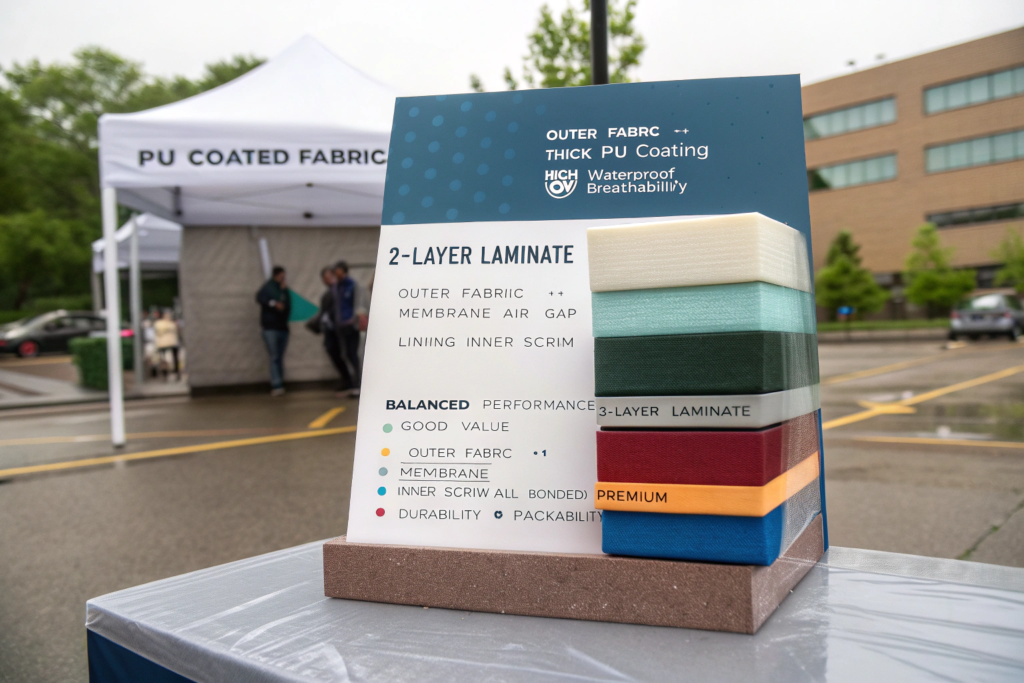

What's the difference between laminated (2L/3L) and coated fabrics?

- Laminated Fabrics (The High-Performance Standard): These bond a waterproof-breathable membrane (like ePTFE - Gore-Tex, PU, or TPU) to an outer shell fabric.

- 2-Layer (2L): Membrane bonded to the inner side of the outer fabric. Usually requires a separate, loose hanging liner inside the garment for protection. More affordable, slightly less durable, and can feel less "crisp."

- 3-Layer (3L): Membrane sandwiched between the outer fabric and a thin inner scrim (protective layer). This creates a single, robust, and highly packable fabric. It's the premium choice for high-end shells and gloves. Offers the best durability-to-weight ratio.

- Coated Fabrics: A layer of waterproof polymer (like PU or PVC) is directly applied to the back of the fabric.

- Pros: Generally more affordable, excellent waterproofness, and can be very durable.

- Cons: Lower breathability. The coating can degrade with flexing and abrasion over time ("cracking").

- Best For: Budget rainwear, simple shells, gear where breathability is less critical (like rain covers, simple tents).

For a mountain guide's hard-shell jacket, a 3L lamination with a robust face fabric (e.g., 40D-70D Nylon) is the standard. For a stuffable emergency rain poncho, a lightweight PU-coated polyester is perfectly adequate.

When should you use ripstop, ballistic, and Oxford weaves?

The weave pattern is the first line of defense against the elements.

- Ripstop: Identified by a grid pattern of thicker reinforcement threads. Designed to localize tears. Used in everything from ultralight tents and wind jackets to premium down apparel. Denier ranges from ultralight (7D) to durable (30D-70D).

- Ballistic Nylon: Originally for flak jackets. A very tight, thick 2x2 basket weave (often 1050D or higher). Extremely abrasion-resistant but stiff and heavy. Used in the most demanding backpack and luggage panels.

- Oxford Weave: A basket weave (typically 2x1 or 2x2) that creates a textured, robust fabric. More flexible and packable than ballistic. Common in mid-weight gear bags, duffels, and some softshells (e.g., 600D Polyester Oxford).

In 2023, we developed a custom 30D ripstop nylon with a matte, printed camouflage pattern for a hunting gear brand. The ripstop grid was integrated into the print design, maintaining the aesthetic while providing essential tear resistance in brush.

Which fibers dominate the outdoor industry?

At the molecular level, the choice of fiber determines a fabric's baseline personality: its strength, elasticity, resistance to UV and chemicals, and how it manages moisture. Nylon and Polyester are the two titans, each with distinct advantages. Blending them or using specialized high-performance fibers addresses specific weaknesses.

This is the "raw ingredient" decision that everything else builds upon.

Why is nylon favored for durability and polyester for weather resistance?

- Nylon (Polyamide):

- Strengths: Superior abrasion resistance, tear strength, and elasticity (better recovery from stretching). Softer hand feel.

- Weaknesses: Absorbs water (can feel wet and heavy), less UV-resistant (degrades in sunlight over time unless treated).

- Best For: High-wear areas (backpack bottoms, knee patches), climbing ropes, softshells where stretch is key.

- Polyester:

- Strengths: Excellent UV resistance, hydrophobic (dries incredibly fast, doesn't absorb water), retains strength when wet.

- Weaknesses: Less abrasion-resistant than nylon of the same denier, less elastic (more prone to permanent deformation).

- Best For: Outer shells of rainwear (where staying dry is key), tents and awnings (constant sun exposure), insulation (hollow-core fibers for synthetic fills like PrimaLoft®).

A classic application is a backpack with a nylon body for durability and polyester panels in high-sun/wet areas. A tent might use a polyester rainfly for UV resistance and a nylon floor for abrasion resistance.

What are the roles of specialized fibers like Dyneema® and Cordura®?

These are not new fibers, but branded, engineered versions of existing ones with guaranteed performance specs.

- Dyneema®/Cuben Fiber (Ultra-High-Molecular-Weight Polyethylene - UHMWPE): The king of strength-to-weight ratio. It's lighter than water and stronger than steel by weight. Used in ultralight backpacking packs, sailing sails, and the most extreme weight-saving gear. It is expensive and can have challenges with lamination and seam sealing.

- Cordura®: A branded high-tenacity nylon known for exceptional abrasion resistance. It's not a single fabric but a certification of performance. You can get Cordura® in various deniers (e.g., 500D, 1000D) and weaves. It's a guarantee of durability.

- Kevlar®/Aramid: Used in extreme cut and heat resistance applications, like chainsaw chaps or fire-resistant gear. Too stiff and expensive for general outdoor use.

For sourcing, it's crucial to understand that using these branded fibers often requires licensing and purchasing from authorized yarn suppliers. We guide our clients through this process to ensure authenticity and performance.

How to source and specify technical outdoor fabrics?

Sourcing outdoor fabric is a technical procurement exercise. You're not just buying a commodity; you're specifying a performance component. This requires detailed technical data, a clear understanding of the supply chain, and often, a willingness to pay for testing and certification.

Your relationship with the mill or converter must be collaborative and technical. They should function as an extension of your R&D team.

What technical data should you demand from a supplier?

Never accept a fabric based on marketing claims alone. Demand these test reports from an accredited lab:

- Hydrostatic Head Test (ISO 811 or AATCC 127): Proof of waterproofness (mm H₂O).

- Moisture Vapor Transmission Rate (MVTR) Test (ISO 15496 or ASTM E96): Proof of breathability.

- Martindale/Taber Abrasion Test (ASTM D4966): Proof of durability.

- Tear Strength Test (ASTM D5587): Measured in Newtons.

- UV Resistance Test (AATCC 16 or ISO 105-B02): For colorfastness and fiber degradation.

- DWR Durability Test (AATCC 22 or 193): Shows how many washes the water-repellent finish will last.

A reputable supplier will have this data on file for their standard fabrics. For custom developments, budget for this testing as part of your R&D cost.

How to navigate the supply chain for laminates and coatings?

The supply chain for high-tech laminates is complex and tiered.

- The Layers:

- Fiber Producer (e.g., nylon/polyester chips).

- Yarn Spinner (creates the high-tenacity yarn).

- Weaver/Knitter (creates the face fabric).

- Membrane Producer (e.g., manufacturers of ePTFE, PU, or TPU film).

- Laminator/Coater (bonds the membrane or applies coating to the fabric).

- Finisher (applies DWR, calendaring, etc.).

- Your Sourcing Strategy:

- Option A: Work with a Vertical Mill/Converter: A company that controls or tightly integrates most of these steps (like Gore-Tex fabric partners or major mills like Toray). This offers consistency and simplicity.

- Option B: Work with an Integrator (like Fumao): We manage the complexity for you. We source the face fabric from our weaving partners, work with our chosen laminators, and conduct the final finishing and QC in-house. This offers flexibility and customization at a lower MOQ than going directly to a vertical giant.

For a startup developing a new tent line, we acted as the integrator: sourcing a custom-width UV-stabilized polyester, managing the silicone coating process with a specialist, and conducting the final seam-sealability tests, all with an MOQ they could handle.

Conclusion

Selecting the best fabrics for outdoor and adventure gear is a rigorous exercise in applied engineering, not aesthetic selection. It begins by defining the non-negotiable performance thresholds for waterproofness, breathability, and durability, understanding the inherent trade-offs between them. This leads to a fundamental choice between laminated membrane systems for high-performance, breathable protection and coated fabrics for cost-effective, robust waterproofing. The foundation is laid by the choice of fiber—nylon for supreme durability and elasticity, polyester for weather resistance and quick drying—augmented by specialized fibers like Dyneema® for ultimate strength-to-weight. Finally, successful sourcing requires demanding validated technical data and navigating a multi-tiered supply chain, often best done through a knowledgeable integrator who can translate performance specs into production-ready fabric.

This process ensures that the materials you choose are not just suitable, but are objectively engineered to enhance the safety, comfort, and performance of the end-user in demanding environments. It transforms a fabric from a component into a core feature of the product's value proposition.

Ready to engineer the fabric foundation for your next generation of outdoor gear? At Shanghai Fumao, our Technical Textiles Division specializes in sourcing, developing, and testing high-performance fabrics for the outdoor industry. From managing custom laminations to providing full test dossiers, we provide the expertise and supply chain access to turn your most demanding specs into reality. Contact our Business Director, Elaine, to begin: elaine@fumaoclothing.com.