You've finalized your design, placed your fabric order, and your production calendar is set. Then, the email arrives: "Due to yarn delays, production will be pushed 2 weeks." Or worse, your finished fabric is sitting at a congested port while your factory's lines sit idle. These delays aren't just inconvenient—they erode margins, miss critical market windows, and damage client relationships. So, how do you build a supply chain that's resistant to the endless list of things that can, and do, go wrong?

Avoiding delays isn't about finding a single magic bullet; it's about implementing a system of proactive defense. It requires treating your fabric supplier not as a vendor, but as a strategic partner in risk mitigation. From the molecular level of raw material sourcing to the final container load, every step holds potential bottlenecks that must be managed before they become crises.

From our nerve center in Keqiao, we see the domino effect of delays daily. The brands that navigate this successfully are those who plan for complexity, communicate with precision, and build buffers into every timeline. Let's deconstruct the major risk points and build a practical playbook for keeping your fabric—and your entire production schedule—on track.

What are the most common causes of production delays?

Delays rarely come out of nowhere. They are the symptom of a breakdown in one of the fundamental pillars of the manufacturing process: material flow, capacity management, or quality control. Identifying these root causes is the first step to building preventative measures.

Think of production as a relay race. If the first runner (raw material) is late, every subsequent runner (yarn, fabric, finishing) is thrown off. Your job is to ensure every handoff is seamless.

How do raw material shortages and quality issues cascade?

This is the origin point of most significant delays. The global supply of key fibers (cotton, polyester staple, wool tops) is subject to volatility from weather, politics, and logistics.

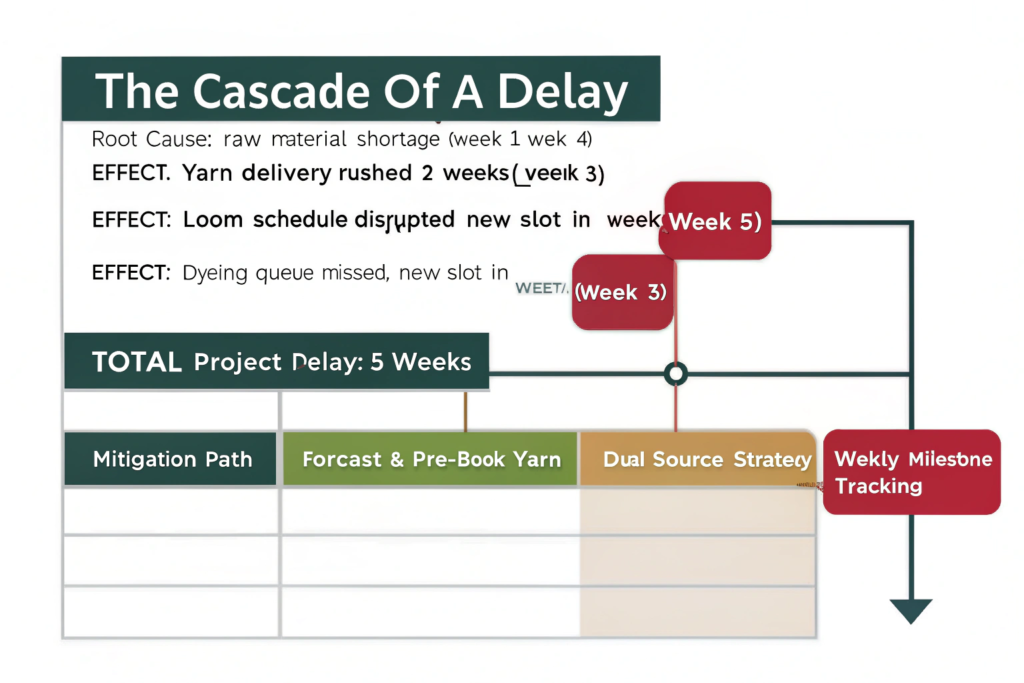

- The Domino Effect: A drought in a key cotton region drives up prices and slows supply. Your supplier's usual yarn source runs out. They must find a new spinner, whose yarn may have a different dye affinity, leading to lab dip rejections and re-work. A 2-week yarn delay can easily become a 5-week fabric delay.

- The Mitigation Strategy: Work with suppliers who have strong upstream partnerships and transparent yarn sourcing. Ask: "What is your primary and secondary source for this fiber? Do you hold safety stock of key yarns?" At Shanghai Fumao, for critical projects, we often pre-book yarn capacity 3-6 months ahead based on our clients' forecasts. This locks in both supply and price.

- Case Example: In early 2024, a surge in demand for GRS-certified recycled polyester caused a global shortage of chips. Because we had forecasted this with several of our sustainable brand partners, we had already secured contracted volumes with our recycling partner. Their production proceeded on time, while competitors faced 8+ week delays.

Why is inefficient communication the silent killer of timelines?

A delay itself is often less damaging than the surprise of a delay. Poor communication turns a manageable setback into a crisis.

- The "Black Box" Problem: When you send an order into a factory and hear nothing for weeks, you have no visibility. Is it on schedule? Has a problem arisen? This lack of transparency prevents you from activating contingency plans.

- The Solution - Structured Updates: Demand a weekly production status report, not just an email saying "it's fine." This report should include:

- Photo/video evidence of the production stage (e.g., yarn on cones, fabric on the loom, fabric in the dye bath).

- Confirmation of key milestones (e.g., "Yarn received," "Weaving completed 40%").

- Any anticipated issues for the coming week.

- The Language of Precision: Vague terms are the enemy. Replace "soon" and "almost done" with dates and percentages. "Fabric will be off the loom by EOD Friday, March 15th" or "Dyeing is 70% complete."

Establishing this communication protocol upfront is non-negotiable. It transforms your supplier from a passive order-taker into an accountable project manager.

How to plan your order timeline with built-in buffers?

The most dangerous plan is an optimistic one. A realistic timeline isn't the supplier's quoted "best-case" lead time; it's that lead time plus strategically placed buffers for the known unknowns. This is called "schedule resilience."

Your goal is to create a timeline that can absorb shocks without breaking. This requires a fundamental shift from asking "How fast can you do it?" to "What is a reliable date, and where are the points of flexibility?"

What is a realistic lead time from order to ship?

As a rule of thumb, take the supplier's standard lead time and add 20-30% for a reliable planning date.

- Standard Fabric Production (Woven/Knit): 8-12 weeks from order confirmation to FOB port is a robust planning figure for a new order. This includes:

- Yarn procurement/transfer: 1-2 weeks

- Weaving/Knitting: 2-3 weeks

- Dyeing/Finishing: 2-3 weeks

- QC, packing, documentation: 1 week

- Buffer: 2 weeks (distributed across the above stages)

- Complex or Custom Fabrics: For fabrics requiring custom yarn development, jacquard looms, or special finishes (e.g., mercerization, coating), 12-16 weeks is more realistic.

- The Critical Path: Always identify the single longest, most inflexible part of the process (often custom yarn spinning or loom setup for complex patterns) and build your schedule backwards from its completion date.

We provide clients with a visual Gantt chart timeline at the order confirmation stage, highlighting these critical paths and buffer zones. This shared document becomes the single source of truth for the project.

How to use forward booking and phased payments to secure capacity?

In a seller's market, capacity is a commodity you must purchase in advance.

- Forward Booking (Capacity Reservation): For seasonal or large orders, negotiate and pay a deposit to reserve production slots on specific loom or dyeing lines months in advance. This guarantees your place in the queue. This is standard practice for major brands.

- Phased Payments Tied to Milestones: Structure your payments to align with progress and maintain leverage. A common structure is:

- 30% deposit with order confirmation.

- 40% upon approval of pre-production sample (PP sample) and evidence bulk production has started.

- 30% balance upon completion, before shipment, after passing final inspection.

- The Leverage: This payment schedule ensures the supplier has a financial incentive to hit milestones. If production hasn't started, your second payment isn't released, protecting your capital.

A European brand we work with now places their capacity reservations for Fall/Winter fabrics in January, with final designs and colors confirmed in March. This locks in their slot and shaves 3 weeks off the peak-season crunch.

What are the best strategies for navigating logistics bottlenecks?

Your fabric is finished, passed QC, and packed. Now it enters the most unpredictable phase of its journey: global logistics. Port congestion, vessel space shortages, rail strikes, and customs inspections are wildcards that can add weeks of delay. You must manage this phase as actively as you managed production.

Logistics is not your forwarder's problem alone; it's a shared risk that requires shared strategy and constant monitoring.

How to choose the right Incoterm and forwarder relationship?

Your choice of Incoterm defines who controls the journey and when risk transfers.

- FOB (Free On Board) [Recommended for Control]: You own the goods once they're loaded on the ship at the origin port. You (or your designated freight forwarder) control the choice of shipping line, route, and destination logistics. This gives you maximum visibility and control.

- EXW (Ex Works): You take control at the supplier's factory door. This requires you to manage all China-side trucking, port logistics, and customs export—a complex task unless you have a strong local agent.

- The Forwarder Partnership: Don't just get quotes; partner with a forwarder who has a dedicated China desk and strong relationships with carriers. They can provide "space guarantee" bookings (not just standby) and have better insight into port congestion.

- The Digital Trail: Ensure your forwarder provides real-time container tracking (not just vessel tracking) and proactive alerts for any gate-in or customs hold issues.

Why is documentation accuracy your last line of defense?

A single error on a commercial invoice or packing list can trap your container in customs for weeks.

- The Critical Docs: Commercial Invoice, Packing List, Bill of Lading, and Certificate of Origin (crucial for tariff purposes). For fabrics, the Harmonized System (HS) code must be precise (e.g., 5208.11 for unbleached cotton poplin vs. 5208.12 for bleached).

- The Process: Implement a documentation review protocol where your team cross-checks every field against the order details before the supplier submits them to the carrier. A discrepancy in weight or value is a red flag for customs.

- Pre-Clearance: In some corridors, your forwarder can begin the destination customs clearance process while the vessel is still at sea, shaving days off the dwell time.

We've integrated with digital documentation platforms that allow our clients to review and approve packing lists and invoices digitally, with a full audit trail, reducing errors and speeding up the process by 3-5 days.

How can technology and partnerships prevent last-minute surprises?

In the 21st century, flying blind is a choice. Technology platforms exist to provide supply chain transparency, and strategic partnerships can turn your supplier into a proactive ally rather than a reactive link. Leveraging both is the final layer of your delay-prevention armor.

The goal is predictive awareness: seeing a problem coming before it arrives, so you can adjust.

What role does real-time tracking and data sharing play?

Visibility = Control.

- Supplier Portals/PLM Integration: Leading mills and suppliers offer client portals. At Shanghai Fumao, our portal provides a dashboard showing: order status, QC report uploads, estimated completion dates, and even photos from the factory floor. This kills the "check-in" email.

- IoT and Tracking: For high-value shipments, smart shipping tags can provide real-time location, temperature, and humidity data. While not standard for all fabric, it's valuable for sensitive materials like woolens or coated fabrics.

- Data-Sharing Agreements: Share your sales forecasts (even if approximate) with your key fabric supplier. This allows them to plan their raw material purchases and capacity, making your actual orders faster and more reliable. They become an extension of your planning department.

Why is a true partnership better than multiple bids?

Constantly switching suppliers for the lowest price is a high-risk strategy for delay. A deep partnership with one or two core suppliers offers stability.

- The Partnership Dividend: A valued, long-term partner will:

- Prioritize your order when capacity is tight.

- Be honest about challenges early, so you can plan.

- Invest in processes that benefit you (e.g., faster sampling, specialized finishes).

- Go the extra mile during a crisis (e.g., trucking fabric to a different, less congested port).

- The Cost of Fragmentation: Managing multiple new suppliers multiplies your risk of communication errors, quality inconsistencies, and logistical headaches. Consolidating volume with a capable partner often yields better pricing and reliability than spreading it thin.

Our most successful clients treat us as their Mills & Materials Department. We attend their seasonal line reviews, understand their calendar pressures, and manage the complexity of their fabric portfolio so they don't have to. This deep integration is the ultimate buffer against delay.

Conclusion

Avoiding delays in fabric production and shipping is a deliberate discipline of proactive risk management. It requires understanding and mitigating the cascade that starts with raw material volatility and poor communication. It demands building realistic, buffered timelines and using financial tools like forward booking to secure capacity. It necessitates actively managing logistics through informed Incoterm choices and impeccable documentation. Finally, it is supercharged by leveraging technology for real-time visibility and cultivating deep, strategic partnerships that prioritize your success over transactional gain.

This holistic approach transforms your supply chain from a fragile sequence of hopeful handoffs into a resilient, predictable, and manageable engine. It moves you from being a victim of circumstances to being the architect of your own reliability.

Tired of delays dictating your success? At Shanghai Fumao, we are built to be your partner in predictability. Our integrated supply chain, transparent tracking systems, and partnership ethos are designed to deliver not just fabric, but on-time certainty. Let's build a schedule you can trust. Contact our Business Director, Elaine, to plan your next season with confidence: elaine@fumaoclothing.com.