You're designing a lingerie collection that needs to feel like a second skin—luxurious, supportive, and irresistibly comfortable. But when you start sourcing, you're met with a bewildering array of lace, elastics, sheer meshes, and powdery-soft fabrics. How do you navigate this specialized world to find materials that don't just look beautiful in a swatch, but perform perfectly on the body through wear and wash?

The secret lies in understanding that lingerie fabric is a system, not a single material. It's about the synergy between face fabric, lining, elastic, and hardware. Success requires a technical eye for stretch recovery, fiber content for breathability, and a tactile sense for what feels truly luxurious against sensitive skin. This is where textile engineering meets intimate apparel design.

From our work with brands ranging from boutique startups to large-scale manufacturers, we at Shanghai Fumao know that the wrong elastic or a non-breathable lining can doom an otherwise stunning design. Let's demystify the process and build a framework for sourcing fabrics that will make your intimates line not just beautiful, but technically brilliant and beloved by customers.

What are the essential fabric types for lingerie construction?

Lingerie fabrics fall into distinct functional categories: the beautiful outer face, the supportive and shaping base, the comfortable lining, and the functional elastics. Each category has non-negotiable performance criteria. Sourcing isn't about picking one perfect fabric; it's about assembling a compatible wardrobe of materials that work together.

Getting one category wrong can compromise the entire garment's fit, comfort, and durability. Let's define the core players in the intimates fabric system.

Why are lace, mesh, and satin the go-to face fabrics?

These materials provide the aesthetic signature and first-skin feel.

- Lace: The queen of lingerie. Not all lace is created equal.

- Leavers Lace: The gold standard. Made on antique-style looms, it has a fine, non-stretch background (the ground) with intricate, raised patterns. It's luxurious, expensive, and has minimal give.

- Raschel Lace: Knitted on modern machines, often with stretch (thanks to Lycra®). More affordable, versatile, and durable. Ideal for strappy details and areas requiring flexibility.

- Stretch vs. Non-Stretch: This is critical for pattern making. A non-stretch Leavers lace needs to be mounted on a stretch base fabric (like powernet) for a bra cup, while a stretch Raschel lace can be used more freely.

- Mesh & Tulle: These sheer fabrics provide coverage with a hint of mystery. For lingerie, you need stable, power, or stretch meshes that resist runs and provide light support. Standard craft tulle is too scratchy and unstable.

- Satin: For a smooth, lustrous look. In lingerie, you almost always use stretch satin (e.g., polyester or nylon with 15-20% Lycra®). It must have excellent recovery—the ability to snap back after stretching—to maintain shape in panties or bra cups.

A common mistake is sourcing a beautiful lace without considering its compatibility with the underlying cup fabric. The stretch properties must match, or the garment will pucker or distort.

What makes a good lining and powernet for support?

This is the hidden engineering that makes lingerie functional.

- Linings: Directly against the skin, they must be supersoft, breathable, and moisture-wicking. Common choices include:

- Cotton Jersey: Breathable and natural, but can lose shape. Often a 95% cotton, 5% Lycra® blend.

- Microfiber (Polyester or Nylon): The industry standard for feel. A finely woven, brushed microfiber feels "powdery" soft and has excellent durability and moisture management.

- Modal or Tencel™ Blends: Offer superior softness and breathability for premium lines.

- Powernet & Support Fabrics: These are the workhorses for bras, corsets, and shaping briefs. They are double or triple-knit meshes with high spandex content (often 20-30%).

- Function: They provide multidirectional control and memory. The higher the spandex content and the tighter the knit, the firmer the support.

- Weight: Ranges from light control for bralettes to heavy-duty for medical or high-impact sport support.

For a successful sourcing trip, always ask for the fabric's weight (GSM) and spandex percentage. A 180 GSM powernet with 28% spandex will behave very differently from a 120 GSM mesh with 15% spandex.

How do you select the right elastics and findings?

If the fabrics are the body of the lingerie, the elastics and findings are the bones and joints. They are the unsung heroes that ensure fit, comfort, and longevity. Cheap or poorly specified elastics will roll, dig in, lose recovery, and ruin an otherwise perfect garment. This is an area where cost-cutting is glaringly obvious to the wearer.

Specifying elastics is a technical exercise in width, composition, modulus, and recovery force. It requires working closely with a specialized supplier or a mill that offers trim solutions.

What are the different types of lingerie elastic?

Each elastic has a specific job. The main categories are:

- Plush-Backed Elastic (Picoot or Picot Elastic): This has a soft, brushed (plush) backing on one side and a decorative picot edge on the other. It's designed for comfort at the leg and waist openings of panties, where it sits directly against the skin. The plush prevents chafing.

- Fold-Over Elastic (FOE): A versatile elastic that can be folded over a fabric edge and stitched, creating a clean, finished binding in one step. Often used for straps, bralettes, and bikini edges. It comes in many finishes (matte, shiny, decorative).

- Strapping & Non-Roll Elastic: Used for bra straps and underband elastics. They are designed to stay flat and not twist. "Non-roll" features a special knit or treatment to prevent curling. They have specific recovery strength to provide support without stretching out.

- Clear Elastic (Polyurethane): Used for invisible seam stabilization, especially in areas of tension like shoulder seams or side seams. It's not for decorative edges.

A critical specification is the elastic's "modulus"—its resistance to stretching. A high-modulus elastic for an underband provides firm support, while a low-modulus plush elastic for a leg opening offers gentle containment.

How to choose hooks, rings, and sliders?

Hardware must be strong, smooth (to not catch on fabrics or skin), and corrosion-resistant.

- Material: Stainless steel is standard for durability and nickel-free safety. Zinc alloy can be used for more decorative, lower-stress applications.

- Finish: Ensure the finish (matte, shiny, painted) is durable and won't chip with washing.

- Sizing: Hooks & eyes come in specific widths (e.g., 10mm, 12mm). Rings and sliders must match the width of your strapping.

- Testing: Always request SALT SPRAY TEST reports for metal findings to ensure rust resistance. For snap fasteners, check the pull-through strength.

In 2023, we worked with a sustainable brand that needed GOTS-certified organic cotton elastics. The challenge was finding a supplier who could produce elastics with the necessary recovery while meeting the organic standard for the rubber/spandex component—a niche but growing segment of the market.

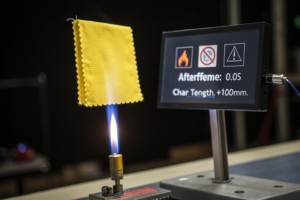

What are the key performance and compliance factors?

Lingerie lives in a demanding environment: body heat, moisture, constant movement, and frequent washing. Performance testing isn't a luxury; it's a prerequisite for customer satisfaction and brand reputation. Furthermore, as intimate apparel, it is subject to strict safety and chemical regulations.

Your sourcing checklist must include both physical performance benchmarks and regulatory compliance certificates. This is where you move from a designer to a product developer.

How to test for durability, comfort, and colorfastness?

Before bulk ordering, your fabric and trim system must pass these tests:

- Stretch & Recovery (ASTM D2594): The most critical test. Fabric is cyclically stretched to a specified percentage (e.g., 50%) for a set number of cycles (e.g., 500). The percentage of permanent set (how much it doesn't recover) should be very low (<10-15%). Poor recovery means sagging garments.

- Colorfastness to Perspiration (AATCC 15) & Washing (AATCC 61): Essential for intimates. Dyes must not migrate onto skin or other garments.

- Dimensional Stability (AATCC 135): How much does the fabric shrink after washing? This must be factored into pattern grading.

- Pilling Resistance (ASTM D4970): Especially important for brushed fabrics like microfiber linings.

- Hand Feel & Wash Durability: Subjectively, does the fabric remain soft after 5, 10, 20 home launderings? Does the plush on elastic flatten out?

We advise clients to create a wash-test protocol for their prototype. Wear it, wash it (following care instructions), and repeat. Note any changes in fit, feel, or appearance. This real-world test often reveals issues lab tests miss.

What are the compliance regulations (CPSIA, REACH, OEKO-TEX)?

Intimate apparel has direct and prolonged skin contact, making chemical safety paramount.

- OEKO-TEX® Standard 100, Class I: This is the minimum baseline requirement for babywear and items with direct skin contact. It tests for over 100 harmful substances. For lingerie, Class II (for articles worn close to the skin) is also common. This certification should cover all components: fabric, thread, elastics, and findings.

- US CPSIA (Consumer Product Safety Improvement Act): Mandatory for children's items (e.g., girls' training bras). It strictly limits lead and phthalate content.

- EU REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Restricts SVHCs (Substances of Very High Concern), including certain AZO dyes and nickel releases.

- California Prop 65: Requires warnings if products contain chemicals known to cause cancer or reproductive harm above safe harbor levels.

Always request OEKO-TEX or similar test reports for each component from your supplier. At Shanghai Fumao, we provide a full component compliance dossier for our lingerie fabric packages, which is a major value-add for brands selling in regulated markets like the EU and North America.

How to source effectively and manage small MOQs?

Lingerie brands, especially emerging ones, face the "small batch paradox": they need high-quality, specialized materials but in quantities far below traditional textile MOQs. Navigating this requires a shift in strategy—from shopping at generic fabric markets to building partnerships with specialized mills and trim suppliers who cater to the intimate apparel industry.

Your goal is to find suppliers whose business model aligns with your scale, without compromising on quality or compliance.

Where to find specialized lingerie fabric suppliers?

- Trade Shows: The most efficient way. Premier events like Interfilière (in Shanghai, Paris, New York) are dedicated exclusively to lingerie, swimwear, and athleisure suppliers. Here, you'll find mills showcasing the latest lace innovations, elastic technologies, and molding techniques all under one roof. It's invaluable for seeing, touching, and building relationships.

- Specialized B2B Platforms & Agents: Look beyond Alibaba. Some platforms and agents focus specifically on sourcing lace and elastics from specialized Chinese mills. They consolidate small orders from multiple brands to meet mill MOQs. Their expertise in the category is worth the potential premium.

- Direct Mill Relationships: For core fabrics (like your standard powernet or microfiber), building a direct relationship with a mill like Shanghai Fumao can be advantageous. We offer small-batch programs with lower MOQs (e.g., 300-500m per color) for development and initial production runs.

A practical tip: at the beginning, source stock fabrics and laces instead of fully custom developments. The MOQs are lower, lead times are shorter, and you can still create unique products through design and fabrication.

How to manage sampling and low MOQ production?

- The Sampling Budget: Be prepared to pay for quality samples. For a custom lace, a "strike-off" (a small sample of the design) can cost $200-$500. This is a necessary R&D cost. Always get physical lace strikes; digital prints are not representative.

- Consolidate Your Palette: Design your collection around a coordinated fabric story. Use the same base powernet, lining, and elastic in multiple styles. This allows you to meet MOQs by aggregating yardage across the collection.

- Communicate Your Growth: Be transparent with suppliers. "Our first order is 500m, but our 12-month forecast is 5,000m if the quality and partnership work." This can motivate them to offer better terms.

- Trim Kits: For elastics and findings, consider ordering a "starter kit" with a small amount of many different components for prototyping, before committing to bulk rolls of each.

One of our most successful startup clients operates on a pre-order model. They finalize designs using our stock fabric library, launch pre-sales, and only then place the bulk fabric order. This minimizes inventory risk and ensures their MOQ is exactly aligned with demand.

Conclusion

Sourcing fabric for lingerie and underwear is a masterclass in balancing art and engineering. It requires a deep understanding of specialized materials—from the aesthetic allure of lace and satin to the hidden support of powernet and the critical comfort of plush elastics. Success hinges on specifying not just for beauty, but for performance: stretch recovery, breathability, durability, and rigorous chemical compliance. Furthermore, it demands a strategic approach to sourcing, leveraging trade shows and specialized partners to access high-quality materials at viable, small-batch quantities.

This process transforms you from a designer into a product developer, building a technical specification package that ensures every component, from the outer lace to the inner hook, works in harmony to create intimate apparel that is beautiful, functional, trustworthy, and comfortable enough to be worn every day.

Ready to source the foundation for your next iconic lingerie collection? At Shanghai Fumao, we specialize in the technical fabrics and trims that power the intimate apparel industry. From OEKO-TEX certified microfibers and a range of powernets to connections with leading lace suppliers, we provide the material solutions and compliance support for brands at every stage. Let's discuss how we can assemble the perfect fabric system for your designs. Contact our Business Director, Elaine: elaine@fumaoclothing.com.