You've found a promising fabric supplier on Alibaba, their prices are competitive, and you're ready to start your first order. But then, the email chain stretches for days over a simple question about fabric weight. A sample arrives, but it's the wrong color. The production timeline you agreed on seems to slip every week. Sound familiar? What are the invisible barriers that turn a simple fabric order into a frustrating ordeal?

The core issue often isn't the supplier's capability—it's a breakdown in communication. Effective communication with a Chinese supplier isn't just about translating words from English to Mandarin; it's about bridging cultural, business, and technical expectation gaps. It's the single most critical skill for ensuring quality, on-time delivery, and a profitable partnership.

With two decades on the ground in Keqiao, I've been on both sides of these conversations. The most successful buyers treat communication as a strategic system, not an afterthought. They build clarity and trust from the very first message. Let's build that system for you, so your next sourcing experience is smooth, efficient, and successful.

How to structure your initial inquiry for maximum clarity?

Your first email sets the entire tone for the relationship. A vague inquiry like "Do you make wool fabric?" will get a generic, low-priority response (and likely a higher quoted price). A detailed, professional inquiry commands respect, gets a faster, more accurate response, and signals that you are a serious buyer worth investing time in.

Think of your initial contact as a filter. You want to filter in suppliers who can handle complex, quality orders and filter out those who can't or who rely on low-price, high-volume transactions with minimal service.

What essential details must be in your first email?

Always include these five pillars of information. This allows the supplier to immediately assess if they can help you and to provide a meaningful quote.

- Clear Product Description: Don't just say "cotton fabric." Specify: "100% Cotton, Mid-weight Twill Weave, for Men's Casual Trousers." If you have a similar fabric, describe it or provide a photo.

- Key Technical Specifications: List measurable data. E.g., "Fabric Weight: 250 GSM (+/- 5%). Width: 57/58". Composition: 97% Cotton, 3% Spandex."

- Intended Use: This is crucial for the supplier to recommend the right finish or quality grade. "For high-stretch activewear leggings requiring 4-way stretch and moisture-wicking finish" is infinitely more helpful than "for sportswear."

- Target Price Range: Be realistic. Stating "Target FOB Shanghai: $3.50 - $4.00 per meter" saves everyone time. It shows you've done your homework and are not just fishing for the absolute lowest number.

- Quantity & Timeline: Provide an estimated order volume (e.g., "First order 2,000m, with potential for 10,000m annually") and your ideal production window (e.g., "Need bulk fabric by October 2025 for Spring '26 production").

A well-structured inquiry immediately puts you in the top 10% of buyers. For example, a Danish brand's first email to us detailed a need for a GOTS-certified organic cotton poplin with specific pilling resistance for hotel uniform shirts, along with their annual volume. We could immediately assign a senior account manager and provide a compliant quote within 4 hours.

Why should you always request a physical swatch book first?

Before discussing price for a custom development, always request the supplier's standard swatch book or physical cutting samples of their nearest existing fabrics. This is non-negotiable.

- Verifies Actual Quality: Photos lie. You need to feel the hand, weight, drape, and see the true color.

- Establishes a Baseline: It gives you and the supplier a common reference point. You can say, "We like the hand of Sample #A-45, but need it in a heavier weight like #B-12."

- Tests Responsiveness: A supplier who is unwilling or slow to send a free swatch book is likely to be unresponsive throughout production.

When you receive the swatches, examine them carefully. Check the edge for fraying, rub it to test for color fastness preliminarily, and hold it up to the light to see density. This due diligence is the first step in building a reliable sourcing relationship with Asian textile mills.

How to master the art of the technical pack (Tech Pack)?

The Tech Pack is the universal language of manufacturing. It's the single source of truth that prevents 90% of errors. In the fabric world, a Fabric Tech Pack is just as critical as a garment tech pack. It translates your creative vision into unambiguous, measurable instructions that a factory can execute without guesswork.

A great tech pack demonstrates your professionalism and makes it easy for the supplier to say "yes, we can do this" or "no, we need to adjust this parameter." It eliminates "he said, she said" disagreements later.

What are the non-negotiable elements of a fabric tech pack?

Your fabric tech pack should be a digital document (PDF) containing:

- Visual Reference: High-resolution photos of the desired fabric or a physical swatch taped to the page (for color).

-

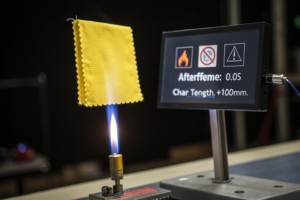

Detailed Specification Table: Parameter Your Requirement Tolerance Test Method Composition 65% Recycled Polyester, 35% Cotton +/- 1.5% AATCC 20A Weight (GSM) 210 g/m² +/- 5% ISO 3801 Width 150 cm (finished) +/- 1 cm - Color & Dye Pantone 19-4052 TCX (Classic Blue) Delta E < 1.0 Spectrophotometer Key Performance Colorfastness to Washing: Grade 4+ AATCC 61 (2A) Finish DWR (Durable Water Repellent) Spray Test: 90+ AATCC 22 - Certification Requirements: Clearly list required certificates (e.g., GRS Certificate with Transaction Certificate, OEKO-TEX Standard 100, Class I for babywear).

- Packaging & Labeling Instructions: How should the fabric be rolled? Polybagged? What information must be on the roll label?

How to use lab dips and strike-offs effectively?

This is the iterative, collaborative phase of communication.

- Lab Dips: These are small swatches dyed to match your specified color (usually Pantone). Your feedback should be precise: "Lab Dip #2 is very close. Please adjust to be slightly less green and 5% deeper." Use a daylight lamp for evaluation.

- Strike-Offs/Sample Yardage: This is a 1-3 meter sample of the full fabric—weave, weight, and finish—in your approved lab dip color. Test this rigorously: wash it, rub it, stretch it. This is your final approval before bulk production. Never approve a strike-off with comments like "it's okay." It must be perfect. Any comment like "the hand is a bit stiff" should be addressed with a finishing adjustment before bulk.

In 2023, a US outerwear brand provided us with a tech pack for a recycled nylon shell fabric that included a video of the desired "dry-touch" rustle sound. This unusual but specific detail helped our finishing team perfectly calibrate the coating process. That's next-level communication.

How to navigate cultural and business norm differences?

Communication styles and business expectations can differ significantly. What you consider direct, your Chinese counterpart might perceive as rude. What they consider a polite avoidance of "no," you might see as evasiveness. Bridging this gap is essential for building trust—the true currency of business in China.

This isn't about stereotypes; it's about practical adjustments to your communication style that yield better outcomes. Respect and patience are your most valuable tools.

Why is building guanxi (relationship) more important than a contract?

In the West, the contract is king. In China, the relationship (guanxi) is the foundation upon which the contract sits. A supplier with a strong relationship will move mountains for you when problems arise; a supplier with only a contractual connection will do the bare minimum.

- Invest Time: Have video calls. Show your face. Ask about their team, their factory. Share appropriate details about your brand.

- Be Patient: Decisions may take longer as they involve more people and consensus-building.

- Show Respect: Understand major Chinese holidays (Chinese New Year, Golden Week). Sending a simple greeting during these times is appreciated.

- Visit if Possible: Nothing builds guanxi faster than a face-to-face meeting, sharing a meal, and touring the factory together. It transforms you from an email address into a partner.

A long-term client from Australia makes a point to have a 15-minute video call with her account manager at Shanghai Fumao every quarter, not to discuss urgent orders, but just to check in. This relationship meant that during a port strike delay last year, our team personally drove her fabric to a different port to catch an earlier vessel—an effort far beyond any contract clause.

How to interpret common responses and avoid misunderstandings?

Learn to read between the lines and ask clarifying questions.

- "Maybe" or "We will try" often means "No, but I don't want to disappoint you directly." Follow up with: "I understand this may be difficult. What would be the closest alternative you can do reliably?"

- "No problem" can sometimes mean "I acknowledge your request," not "I guarantee it." For critical items, get written confirmation: "Great, so to confirm, you can deliver the strike-off by March 10th. Please send the courier tracking number once it's shipped."

- Avoid Confrontation in Public: Never blame or criticize openly in a group email or call. Address issues privately with your main contact. Public "loss of face" can severely damage the relationship.

- Use Simple, Clear English: Avoid idioms, slang, or complex sentences. "Please make the blue less green" is better than "Can you tweak the hue to be less chartreuse-leaning?"

Resources like the guide to Chinese business culture by HBR can provide deeper cultural context for Western entrepreneurs.

What are the best practices for ongoing order management?

Once the order is placed, communication shifts to proactive management. Your goal is to prevent fires, not fight them. This requires a disciplined system of check-ins, documentation, and escalation protocols. Silence is not golden; it's a red flag.

Establish a clear communication rhythm and stick to it. This predictability reduces anxiety for both parties and ensures small issues are caught before they become big problems.

How to set up a clear milestone payment and update schedule?

Link payments to verifiable, physical milestones and demand regular updates.

- Milestone Schedule Example:

- Deposit (30%): Upon order confirmation and Tech Pack sign-off.

- Second Payment (40%): Upon your written approval of the bulk pre-production sample (PP sample) and receipt of photo/video evidence that bulk fabric production has started.

- Balance (30%): Upon completion, before shipping, after you receive final inspection reports and shipping documents.

- Update Cadence: Agree on a weekly update every Friday, for example. The update should include: 1) Photos of the production line, 2) Status against the timeline, 3) Any anticipated issues.

This system protects your capital and gives you leverage. Never pay 100% upfront. The sample approval milestone is your most critical quality checkpoint.

When and how should you conduct a pre-shipment inspection?

Even with the best communication, a final physical check is essential. You have two options:

- Hire a Third-Party Inspection Company (SGS, BV, Intertek): This is the gold standard for objectivity. They will check quality, quantity, measurements, and packaging against your Tech Pack and report defects impartially. The cost is usually $300-$500 and is worth every penny for orders over $5,000.

- Conduct a Remote Video Inspection: If a third-party is not feasible, schedule a live video call with your supplier at the factory warehouse. Ask them to show you random rolls, measure the fabric, check labels, and demonstrate color consistency across rolls. Record the call.

In one case, a remote inspection for a client revealed that the roll labels had the wrong lot number. We caught it before shipment and re-labeled everything, preventing a customs documentation nightmare for them. This is the power of vigilant, ongoing communication. For a deeper understanding, research the key steps in a fabric pre-shipment inspection.

Conclusion

Effective communication with your Chinese fabric supplier is a multifaceted discipline. It begins with a meticulously detailed initial inquiry that separates you from the crowd, relies on the universal language of a comprehensive tech pack to eliminate ambiguity, and is sustained by an understanding of cultural nuances that builds invaluable trust (guanxi). It culminates in a disciplined system of milestone-based management and rigorous final verification. This end-to-end approach transforms a potentially fraught transaction into a smooth, reliable, and collaborative partnership.

Mastering this process does more than just get you fabric; it builds a resilient supply chain asset. A supplier who understands your standards, respects your professionalism, and values your relationship becomes an extension of your own team—a partner in innovation and problem-solving, not just a vendor.

Ready to transform your supplier communications from a source of stress into a competitive advantage? At Shanghai Fumao, we are built for this kind of partnership. Our bilingual account managers, standardized tech pack processes, and proactive update systems are designed to provide the clarity, transparency, and reliability you need. Let's communicate clearly from the start. Contact our Business Director, Elaine, to begin a truly effective partnership: elaine@fumaoclothing.com.