You're committed to building a sustainable fashion line, but navigating terms like "deadstock," "upcycled," and "post-consumer recycled" feels like walking through a minefield of greenwashing. Where do you actually find these materials at scale, verify their claims, and integrate them into a reliable production schedule? Is it even possible to build a consistent brand around inherently inconsistent materials?

The answer is a resounding yes—but it requires a completely different sourcing mindset. You're not just buying fabric; you're becoming a supply chain detective, a relationship builder, and a flexible designer. Success means moving beyond one-off "eco capsules" to systematic sourcing strategies that make sustainability a core, operational reality.

From our base in Keqiao, the world's textile clearinghouse, we see the entire lifecycle. Sourcing sustainable materials isn't about finding a secret website; it's about understanding the channels where excess flows and building trust within them. Let's map out a practical, actionable guide to sourcing deadstock and recycled fabrics for your 2025 line and beyond.

Where are the most reliable sources for deadstock fabric?

Deadstock (also called surplus or overstock) refers to first-quality, unused fabric that mills, manufacturers, or brands did not use. It's not waste; it's excess inventory. The key to reliable sourcing is tapping into the specific points in the supply chain where this excess systematically accumulates. It's about finding the "wholesalers" of leftover material.

Your approach must be multi-pronged. Relying on a single source is antithetical to the nature of deadstock, which is defined by its variability.

How to connect directly with mills and factories?

This is the gold standard for quality and traceability. You get fabric straight from the source, often with full knowledge of its composition and origin.

- Mills: Fabric mills overproduce to meet minimum dye lots or weave runs. They also have sample yardage and discontinued lines. Building relationships here is paramount. At Shanghai Fumao, for example, we maintain a regularly updated "surplus fabric list from mill overruns" for trusted clients. This fabric is pristine, with full test reports, but quantities are finite (usually 500-3000 meters per lot).

- Garment Factories: They over-order fabric by 3-10% as a buffer for cutting. After an order is complete, this leftover fabric, often cut into smaller "piece goods," is available. Connecting requires being on the ground or working with a local agent. In 2023, we helped a Berlin-based brand source high-end Italian suiting remnants from a jacket factory in Prato, Italy, for a limited-edition blazer line. The fabric was impeccable, but the patterns had to be adapted to smaller piece sizes.

What are the best digital platforms and physical markets?

For breadth and accessibility, these channels are indispensable.

- Digital B2B Platforms: Dedicated surplus markets have emerged. Platforms like Queen of Raw, Sourceful, or The Fabricker aggregate deadstock from various sources. They offer searchability but require diligence in verifying the seller's claims. Always request a physical swatch.

- Physical Wholesale Markets: Nothing replaces touching the fabric. In Asia, places like Guangzhou's Zhongda Market or specific warehouses in Keqiao have dedicated surplus sections. In Europe, London's Berwick Street Cloth Shop or Parisian dépôt-ventes are famous. The key is to visit regularly, as stock turns over quickly. A great resource is the Ultimate Guide to Global Fabric Markets for Designers, which lists many surplus hotspots.

- Brand-to-Brand Networks: Some organizations facilitate surplus fabric transfers between larger brands and smaller designers. This is a growing, ethical channel for high-quality materials.

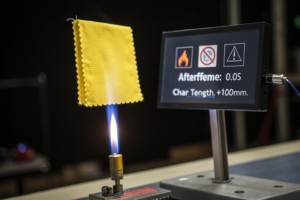

How to verify the authenticity and quality of recycled fabrics?

"Recycled" is a broad term covering everything from plastic bottles turned into polyester to factory scraps turned back into yarn. The risk of fraud or misrepresentation is high. Your brand's integrity depends on rigorous verification. Trust, but verify with certificates and forensic questioning.

The verification process for recycled content is more technical and documentation-heavy than for deadstock. It's a non-negotiable part of your costing.

Which certifications are non-negotiable for recycled content?

Never accept a supplier's word alone. Demand these third-party certificates:

- Global Recycled Standard (GRS): The most important. It verifies the percentage of recycled content (e.g., 50%, 100%) and tracks it through the supply chain via transaction certificates. It also includes environmental and social criteria. This is your baseline requirement.

- Recycled Claim Standard (RCS): A simpler standard that verifies recycled content only.

- OEKO-TEX® Standard 100: While not a recycled standard, it's crucial for ensuring the recycled fabric is free from harmful chemicals—especially important since the source material (e.g., post-consumer plastic) can be contaminated.

A supplier should be able to provide a GRS certificate for their company and a Transaction Certificate (TC) for your specific fabric shipment, tracing the recycled content back to its source. Last year, a client asked us to source GRS-certified 100% recycled nylon for swimwear. We provided the mill's certificate and the TC for the yarn batch, which gave them the confidence to market the line accurately.

What due diligence questions should you ask suppliers?

Go beyond the certificate. Ask pointed questions to uncover their true expertise:

- "What is the post-consumer vs. pre-consumer recycled content percentage?" Post-consumer (e.g., bottles, fishing nets) is generally considered more impactful than pre-consumer (factory off-cuts).

- "Can you explain the mechanical vs. chemical recycling process used?" Mechanical recycling (shredding and melting) is common for polyester but can weaken fibers. Chemical recycling (depolymerization) can produce virgin-quality fiber but is more expensive. Knowing this affects performance expectations.

- "What are the key performance differences (e.g., strength, dye affinity) compared to virgin fiber?" Recycled polyester (rPET) can have a slightly lower melting point and different dye uptake.

- "Can you provide test reports for strength, pilling, and colorfastness for this specific recycled fabric?" Performance can vary.

A resourceful supplier will have this data. If they hesitate, consider it a red flag. For a deep dive, consult resources like the Textile Exchange's Preferred Fiber Materials Guide.

How to manage design and production with variable materials?

This is the creative and operational core of working with deadstock and recycled fabrics. You must design for availability, not the other way around. Your production plan must be agile, and your patterns must be adaptable. This constraint isn't a limitation; it's the birthplace of truly innovative, sustainable design.

Embrace a "craftsperson" mindset over a "mass-production" one. Each batch of fabric is a unique ingredient.

How to design a collection around limited yardage?

Adopt these strategies from successful sustainable brands:

- Modular & Less-Sized Design: Create styles that work across multiple fabrics and where color is less critical. Think unstructured blazers, wrap dresses, or unisex trousers. Use a limited color palette as a unifying theme.

- "Recipe-Based" Design: Instead of designing 3 dresses in 3 colors, design 1 dress that can be made in 9 different deadstock fabrics. Your tech pack becomes a "recipe" for construction, with flexibility on material.

- Zero-Waste Pattern Cutting: Integrate techniques that utilize irregular fabric widths or smaller pieces. This pairs perfectly with factory remnant deadstock. Educate your team or factory on implementing zero-waste patterns in small-scale production.

- Pre-Source, Then Design: The most effective method. Source your deadstock fabrics first, then design your collection around the specific yardages, colors, and textures you have secured. This reverses the traditional process but guarantees feasibility.

A New York-based brand we collaborate with operates on a "Seasonless Capsule" model. Each quarter, they select 8-10 deadstock fabrics from our surplus list. Their designer then creates 4-5 core styles that are adapted to each fabric's width and character, producing limited runs of 50-150 units per fabric. This is their entire business model.

What are the logistics of working with multiple small-batch fabrics?

Your production management needs an upgrade:

- Consolidated Cutting: To maintain efficiency, group all styles using Fabric A for cutting on one day, then all styles using Fabric B the next. This avoids constant machine re-threading and fabric changes.

- Detailed Yardage Tracking: You'll be working with 200m of this, 350m of that. Use a simple but rigorous tracking sheet or software to allocate every meter to a specific style/size, including a buffer for sampling and defects.

- Transparent Communication with Factory: Be upfront about the variable nature of the materials. Agree on a slightly higher defect tolerance if needed, and involve the cutting master early to plan the marker (layout) for optimal yield from each finite roll.

- Batch Labeling: Every garment must be traceable back to its specific fabric lot. This is for your own QC and for authentic storytelling to your customer.

What are the real costs and lead time implications?

The myth: sustainable materials are always more expensive. The reality: the cost structure is different. Deadstock can be cheaper per meter but costlier to manage. Recycled fabrics may have a fiber premium but offer consistency. Understanding the total cost of ownership is critical for your P&L.

Lead times are also inverted. With deadstock, you're racing against others for a finite resource. With recycled, you're waiting for a longer, more complex production pipeline.

Is deadstock fabric actually cheaper?

The answer is: it's complicated.

- Lower Unit Cost, Higher Management Cost: The fabric itself can be 20-50% cheaper than its virgin equivalent. However, you incur costs in:

- Sourcing Time: Hunting for the right material takes hours, not minutes.

- Testing & Validation: You must test each new lot.

- Lower Cutting Efficiency: Working with multiple, finite rolls reduces marker efficiency, potentially increasing fabric waste.

- Higher MOQ for Making-Up: A factory's minimum charge per style may be spread over fewer units, raising the cost per garment.

Your budget must include a "sourcing and complexity" line item of 5-10% to cover these hidden costs. The financial win comes from marketing it as a premium, limited-edition product that commands a higher retail price.

Why do recycled fabrics have longer lead times?

Recycled content adds steps to the supply chain:

- Collection & Sorting: Post-consumer waste must be gathered and meticulously sorted by color and polymer type.

- Processing: Turning bottles into chips or textile waste back into pulp takes time.

- Fiber Production: Spinning recycled fiber can be slower than virgin, as the feedstock is less uniform.

- Limited Mill Capacity: Not every mill is equipped to spin or weave with 100% recycled content, creating bottlenecks.

For a custom order of GRS-certified fabric, add 4-8 weeks to your standard lead time. For example, our lead time for a new development in standard polyester might be 6 weeks. For the same fabric in 100% GRS rPET, it's 10-12 weeks. Planning is everything. This is why forward-thinking brands at Shanghai Fumao are now placing commitments for their Fall/Winter 2026 recycled fabric cores in Q1 of 2025.

Conclusion

Sourcing deadstock and recycled fabrics successfully is a paradigm shift. It moves you from a linear, predictable supply chain to a dynamic, circular ecosystem. It requires proactive hunting across mill overruns and digital platforms, rigorous verification through certificates and technical dialogue, flexible design that celebrates material constraints, and a clear-eyed understanding of the unique cost and timeline structures. The reward is a genuinely sustainable product line with a powerful story and a resilient, future-facing business model.

This journey transforms you from a passive buyer into an active participant in the new textile economy. You're not just reducing waste; you're creating value from what already exists and driving demand for innovative recycling systems. The complexity is real, but so is the competitive advantage and customer connection it builds.

Ready to build your sustainable line on a foundation of integrity and innovation? At Shanghai Fumao, we bridge both worlds. We offer curated, traceable deadstock from our mill network and are a leading supplier of GRS-certified recycled polyester, nylon, and developing recycled cotton blends. We provide the verification, consistent quality in recycled lines, and the production savvy to help you manage variable materials. Let's make your sustainable vision a commercial reality. Contact our Business Director, Elaine, to start sourcing differently: elaine@fumaoclothing.com.